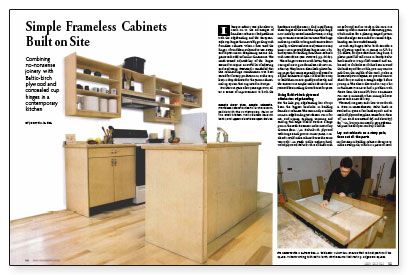

Simple Frameless Cabinets Built on Site

Combining no-nonsense joinery with Baltic-birch plywood and concealed cup hinges in a contemporary kitchen.

Synopsis: A Massachusetts builder shows how simple kitchen cabinets can be made on site with no specialized tools and without complicated joinery. Parts for these contemporary frameless cabinets are made from Baltic birch plywood, joined with a tongue-and-groove joint made on the tablesaw.

I have to admit I was a bit slow to catch on to the advantages of frameless cabinets. I had problems with the edgebanding and the European-style cup hinges that inevitably go along with frameless cabinets. When I first tried the hinges, I found them awkward to use. Setup and layout meant deciphering arcane diagrams with odd, unfamiliar dimensions. The much-touted adjustability of the hinges seemed to require an awful lot of adjusting and readjusting. Frustrated, I concluded that this cabinet-hinge combination was best suited for factory production or, at the very least, a shop dedicated to the 32mm cabinet-making system that originated in Europe.

But that was quite a few years ago. Now, after a series of improvements to both the hardware and the user, I find myself using these hinges all the time. The clip-style hinge, now made by several manufacturers, is a big improvement over earlier versions. This hinge makes it possible to hang and remove doors quickly, without tedious readjustment every time. I incorporated these hinges into a hybrid system for building face-frame cabinets with inset doors.

These hinges were so much better, they encouraged me to give frameless cabinets another try. They have a clean look that seems especially well suited to a spare architectural style. I looked for a way to build them on site quickly and easily, and the answer was simple: Make cabinet boxes just as I’d been making drawer boxes for years.

Using Baltic-birch plywood eliminates edgebanding

For the little guy, edgebanding has always been the biggest headache in building frameless cabinets. The commonly available iron-on edgebanding just doesn’t cut it for me, and ripping, applying, trimming and sanding thin strips of solid stock is a huge pain in the neck. Because I make most of my drawers from 1/2-in. Baltic-birch plywood with tongue-and-groove corner joints, I realized I could make cabinet boxes the same way with 3/4-in. stock. Unlike ordinary hardwood plywood, Baltic birch is all birch with no softwood and no voids in the core. It is made up of thin veneers of alternating grain, which makes for a pleasing striped pattern when the edges are sanded or routed. Edgebanding can be avoided entirely.

As with cup hinges, Baltic birch can take a bit of getting used to. It comes in 5-ft. by 5-ft. sheets, so if you don’t have long arms, a plastic panel lift will come in handy. Baltic birch tends to warp if left unused and unbraced, so if it looks as if it has been around the lumberyard for a while, you may want to pick from the middle of the stack. It also is, notoriously out of square, so you will want to check for (or make) a straight edge before you rip it. The sheets also tend to vary a bit in thickness. I’ve never had a problem with sheets from the same lift, but I sometimes run into a mismatch when mixing leftover pieces with a new delivery.

For more photos and details, click the View PDF button below: