A Stair in the Air

Southern yellow-pine treads hide welded-steel brackets that make these stairs appear to float in space.

Synopsis: This unusual staircase uses welded steel frames to support the treads. Steel supports are hidden from view so treads have no visible means of support.

I have the best client in the world. He likes only the simplest designs for the projects he commissions. And let no degree of complexity stand in the way of those projects.

One particularly interesting project was the stairway in his new home on Nantucket. John, a k a “best client,” claimed that a standard set of stairs supported with framework underneath not only would destroy the character of the hallway entry but that a closed-in stairwell would also make the hallway narrow and claustrophobic. So John suggested eliminating risers between the stairs to let more light pass through.

I’ve always been intrigued with the idea of stringerless stairs and ways of supporting tread load by other means. So I suggested going one step further and getting rid of the stringers as well. The stair would then be reduced to its three basic elements: treads, handrails and balusters. Could it be any simpler?

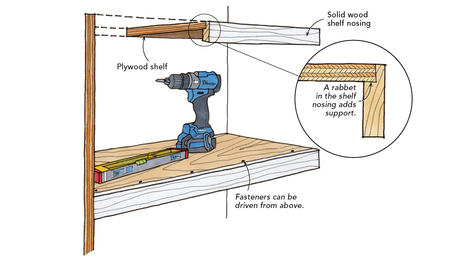

Engineering support

Several designs of stringerless stairs use steel cantilevered from a wall. But most of these designs have an angle brace under the tread to transfer the load back to the wall. We agreed that this brace interfered with simplicity, the visible steel brackets adding another structural element. Plus, we wanted to keep the treads to a minimal thickness and keep all the structural elements hidden. What to do?

Lucky for me, John, in his role as “best client,” has wonderful taste in wine, and we decided to drink some, and have dinner, too. Have I mentioned that any candidate vying for position as best client in the world should have a gracious spouse who is a talented cook? At dinner, we let the wine and food help us to explore our options.

Before I go any farther, I should explain that John is an engineer, the kind who drinks coffee before he goes to sleep. The next morning, John called with a potential solution. He described a system of steel brackets made of flat bar stock that could be attached to the wall framing and be buried in the treads and balusters. The top of each bracket would be bolted to the nose of the tread above while the bottom of the bracket was bolted to the heel of the tread below. The idea sounded reasonable to me.

That afternoon, a fax arrived at my office with the load-deflection calculations, a finite-element stress analysis with bending modes and, of course, graphic interpretations in a gray scale. Unfortunately, I don’t have a color fax. Does anyone?

For more photos, drawings, and details, click the View PDF button below: