Bending PVC Without Kinks

This simple technique lets you bend PVC pipe without any kinks.

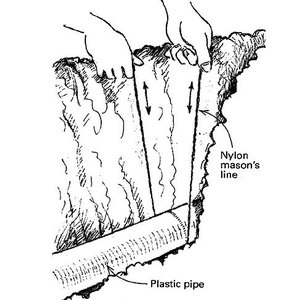

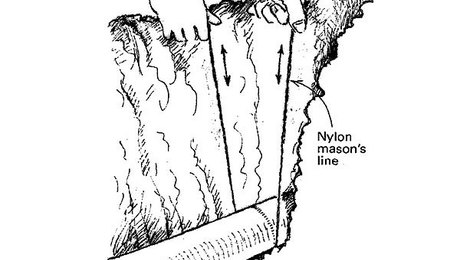

I was having one of those days when even the simplest tasks bring out the worst words in my vocabulary. I had just finished hand-digging a trench up to the house foundation wall and was attempting to install a roll of 3/4 in. PVC pipe. The pipe was rated at 160 psi, so it was the stiff, thick-walled variety. I needed the pipe to exit the trench vertically at an exact spot and, naturally, be plumb as it did so.

This simple task soon degenerated into what seemed like a wrestling match against a snake with an attitude. Everything I tried, including heating the pipe, wouldn’t allow it to make the necessary 90° turn without kinking. It was clearly time to consider my options.

I could dig the trench deeper to give the pipe more room to make a smooth bend, but I vetoed that idea in another flurry of oaths. I thought about cutting the pipe and installing an elbow fitting, but abandoned the idea because the area was to be covered with concrete and I wanted to avoid any opportunities for future leaks. The elbow idea, though, did lead to a final solution.

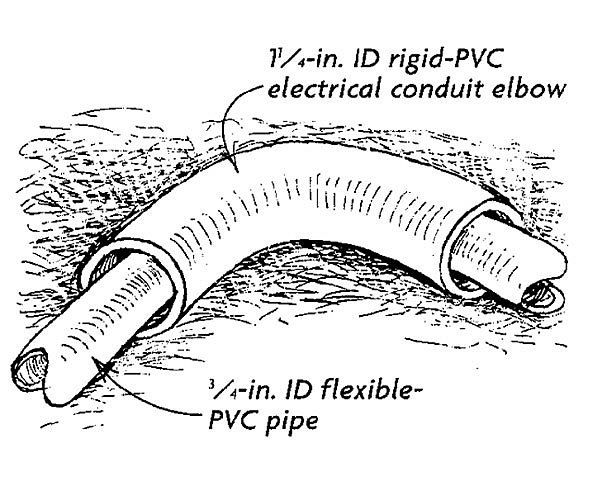

I rummaged through my supplies and pulled out a 1-1/4-in. dia. PVC electrical-conduit elbow. It was fairly easy to push the 3/4-in. line through the larger diameter elbow. As shown in the drawing, this gave me the 90° turn I needed without kinking the pipe.

I set the bent pipe in its final position, encased in its conduit sleeve, and carefully backfilled the trench. Since that discovery, I’ve used this technique several times with good results: smooth bends, no kinks and better language.

— Andy Beasley; Hillside, CO. Edited by Charles Miller.

From Fine Homebuilding #140

RELATED STORIES

Got a Tip?

Do you have any great tips like this one on bending PVC without kinks? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at [email protected], or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

View Comments

Interesting idea, but how does Andy know the 3/4" pipe was not kinked? Did he cut the 1-1/4" pipe off - to check the condition of the 3/4" pipe? It appears that there would be no other way, short of snaking a camera through, to see if the 3/4" pipe was kinked.

Plus, if Andy did not want to use an elbow, he would have to heat and push multiple feet of 3/4" pipe through - to achieve a seamless pipe.