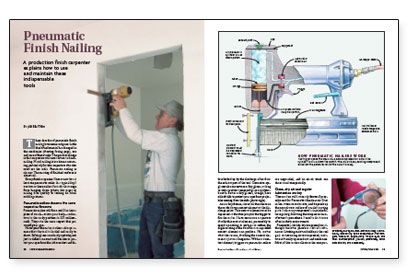

Pneumatic Finish Nailing

A production finish carpenter explains how to use and maintain these indispensable tools.

Synopsis: This article explains how pneumatic finish nail guns work and how they are used on a typical job site. It includes a discussion of safety, tips for maintenance and repair, a discussion of the various types of fasteners and their purpose, and techniques for specific carpentry tasks.

Three decades of pneumatic finish nailing have come and gone. Little that’s fundamental has changed in the mechanics, use and care of these tools. The greatest change is that carpenters will never return to hand-nailing. Hand-nailing is too time-consuming, particularly for trim carpenters who also must set the nails. Pneumatic nailing is cleaner. The marring of finished surfaces is almost nil.

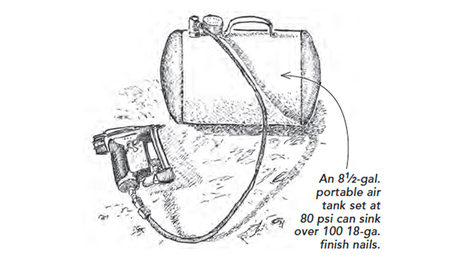

Every finish carpenter I know now has at least one pneumatic nailer. In a typical day, I use two or three nailers for tasks that range from hanging doors to nailing base quickly to tacking on small molding returns.

Pneumatic nailers deserve the same respect as firearms

Pneumatic nailers will fire a nail 2 in. into a piece of wood — or into your body — and return to the ready position in 125 milliseconds. They rate the same respect that you would give a gun.

Never point the nailer at others. Always assume that the tool is loaded and ready to shoot. Safety glasses are clearly a priority, not just to deflect an errant nail but also to protect your eyes from the airborne dust and debris kicked up by the discharge of air from the exhaust port of the tool. Corrective eyeglasses also can serve as safety glasses, as long as they are either tempered glass or polycarbonate. Better safety glasses, though, have side shields to protect your eyes from projectiles coming from the side.

As a safety feature, almost all the nailers on the market have a contact element at the discharge point. This contact element must be depressed at the time you pull the trigger to fire the nailer. I have seen some carpenters disable this contact element, presumably to speed up nailing or perhaps to reduce the slight marring of the wood that an unpadded contact element can produce. No matter what the reason, disabling the contact element is just too dangerous. Without a contact element, triggers on pneumatic nailers are unguarded, and an errant touch can shoot a nail unexpectedly.

Clean, dry air and regular lubrication are key

These nailers will last nearly forever if properly cared for. Pneumatics like clean air. Dust in the airstream is abrasive, and it speeds up the normal wear and tear of a nailer’s moving parts. I clean my compressor’s air-intake filter regularly, following the compressor manufacturer’s procedures. I tend to do it more often in dusty environments.

For more photos, illustrations, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Makita Top-Handle Jigsaw (4350FCt)

Metabo HPT Impact Driver (WH18DBDL2)

Spyder Stinger Spade Bit