Exterior-Trim Details That Last

Flexible caulk joints combined with a drainage path for moisture keep vulnerable trim elements rot-free.

Synopsis: A restoration carpenter explains how to use foam backer rod, caulk and nylon-filament erosion mat to protect exterior trim from water damage. Includes sources for hard-to-find supplies, such as polysulfide sealant.

The old saying “It’s better to be lucky than smart” certainly applies to New Orleans, Louisiana. Considering the rot-acceleration chamber that passes for a climate here, it’s remarkable that New Orleans has more 19th-century houses than any other city in the country. Although it’s tempting to credit the skill of old-time carpenters who built things to last, the only reason all these houses are still standing is luck. When the first Europeans arrived, almost every acre of land in New Orleans was concealed beneath a massive canopy of old growth cypress trees. Clearing the land for development released a seemingly unlimited supply of one of the heartiest building materials on the planet.

The old-timers didn’t worry about back priming, drainage planes or caulking. They just nailed together two pieces of wood and walked away; no fungus was going to take a bite out of a 2,000-year-old chunk of cypress. Do that with the fast-growth sapwood we have to work with today, and you can be sure the forces of decay will start moving in before the extension cords are rolled up.

Caulk is the first line of defense

Among all the places where rot can secure a foothold in exterior woodwork, caulked joints are probably the most vulnerable. Seasonal changes in temperature and humidity cause wooden trim elements to expand and contract. Unless caulk has the flexibility to accommodate this movement, sooner or later, the bead will crack, and water will seep in. From that point on, the caulk actually does more harm than good because it allows water to soak into the wood while it restricts air circulation that would promote drying.

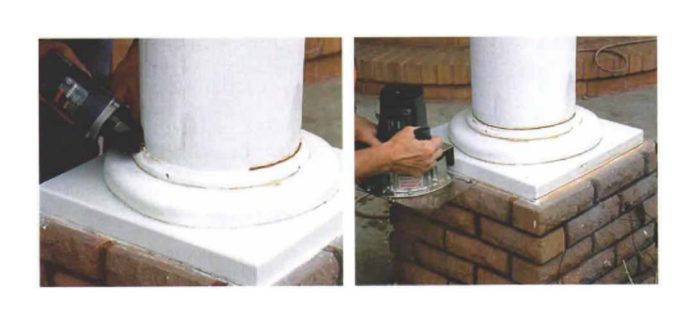

My approach to protecting vulnerable exterior trim is twofold: First, I try to create a caulk joint that can weather many seasons of expansion and contraction. I’ve been around long enough to know that even the best caulk joint will eventually fail, however, so as often as possible, I also build a path for moisture to escape when that happens.

Backer rod gives caulk the freedom to move

There are two ways to create a caulk joint that can handle expansion and contraction: Either reduce the amount of movement, or increase the ability of caulk to move. I do both. Certain species of wood, such as pressure-treated southern yellow pine, are inherently unstable, so I try not to use them when given a choice. For exterior trim, I prefer to use the highest-quality kiln-dried lumber I can find; in my area, that’s either mahogany, Spanish cedar or all-heart redwood. I also fully prime every piece of trim, and I assemble permanent (crackproof) miter joints using biscuits and marine epoxy.

For more photos and details on exterior trim that lasts, click the View PDF button below.