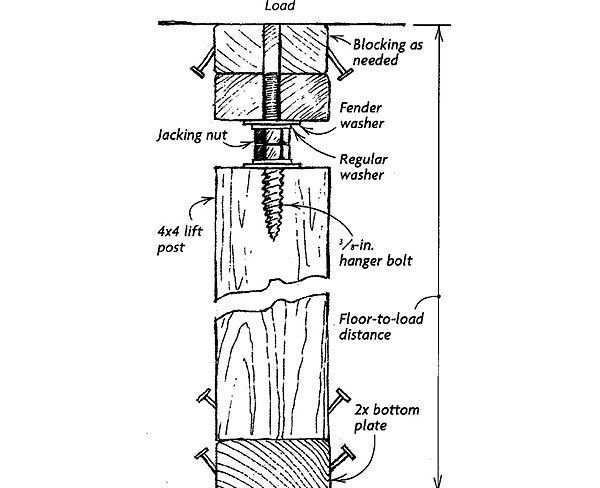

A fully threaded 3/8-in. hanger bolt, a 4×4 post and a few pieces of 2×4 block can be combined to create a short-travel screw jack in just a couple of minutes. As shown in the drawing, the hanger bolt is screwed into the end of the post with the machine-thread end sticking out. A nut, a regular washer and a fender washer bear on top of the post, spreading the load from above. The jacking is accomplished with a second nut (the jacking nut), also topped off with a regular washer and a fender washer to distribute the jacking force over a larger area.

A couple of pieces of 2x blocking are nailed to the load to transfer the lifting force. Clearance holes are drilled in the blocks to accommodate the machinethread end of the hanger bolt.

First, the machine-screw end of the lift post is inserted into the blocks, and once it’s fully seated, a piece of 2x is slipped under the post and secured to the floor. With the setup that is shown here, I made the lift post 5-1/4 in. shorter than the floor-to-load distance. Once I’ve plumbed the lift post, I drive a couple of toenails through its base into the 2x bottom plate to keep the post from becoming dislodged if it is bumped. Because the hanger bolt has fine threads, turning the jacking nut lifts the load slowly, allowing for accurate height adjustments.

Obviously, this type of jack is not meant as a replacement for a house jack. And you should always install redundant supports to keep a load from falling should the jack support fail. That said, however, I’ve had excellent results using these jacks for tasks such as supporting a roof load on a one-story house when installing a header for a large window. The ability to make slight adjustments in height really comes in handy.

Al Lemke, Hopewell Junction, NY

Edited and Illustrated by Charles Miller

From Fine Homebuilding #141

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Handy Heat Gun

Affordable IR Camera

Reliable Crimp Connectors

View Comments

This could be scaled up a bit with all-thread, which is available up 1" diameter, and a 4x4. Use 2 jam nuts and a BIG washer at the bottom, single nut and another BIG washer at the top. Use one wrench on the jam nuts, another on the lifting nut. Because it's taking the pressure on side grain, you might want to use a piece of oak above the top nut, or make a large "washer" by boring a piece of steel to the diameter of your all-thread.