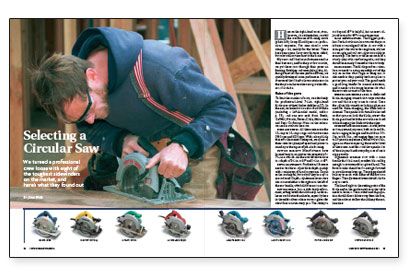

Selecting a Circular Saw

We turned a professional crew loose with eight of the toughest sidewinders on the market, and here's what they found out.

Synopsis: This tool survey focuses on eight professional-quality 7-1/4-in. circular saws without blade brakes, comparing features, specifications, and performance on the job site. There are also small sidebars discussing left-handed saws and blade brakes.

Here on the right-hand coast, circular saws, aka sidewinders, are still the workhorses of framing crews. In my 20-odd years as a professional carpenter, I’ve seen circular saws change a lot, mostly for the better. There have been some fancy new features added, but what still matters most is the basics.

My crew and I had manufacturers send us their best saws, and for the past few months, we put these saws through their paces on framing, finishing and remodeling jobs. Although most of the saws performed well, we quickly developed some preferences. I soon discovered that I had to leave certain saws in the shop to make sure the crew gave the others a fair shake.

Rules of the game

To limit the number of saws, we asked only for professional-level 7 1⁄4-in. right-hand blade saws without brakes. In the end, we looked at two saws from Makita (including a left-handed model), and one saw each from Bosch, DeWalt, Hitachi, Porter-Cable, Milwaukee and Sears Craftsman. Here are the criteria we used to evaluate the saws.

Speed and power

All these saws are in the 13-amp to 15-amp range and run between 5000 rpm and 6000 rpm. With a sharp blade that suits the material being cut, every one of these saws has plenty of speed and power to stand up to the rigors of job-site framing.

Cutting capacity

Manufacturers have learned how to maximize the potential of a 7 1⁄4-in. sawblade. All the saws tested cut close to a depth of 2 1⁄2 in. at 90° and 1 3⁄4 in. at 45°.

Depth adjustment

Professional framers need to be able to adjust blade depth quickly with a minimum of hand movement. Depth scales are helpful, but only if they’re easy to see and read. Depth-adjustment levers were also mounted either to the right or to the left of the saw handle, which didn’t seem to matter.

Setting bevels

Just as with depth adjustment, setting bevels should be easy. Lever releases work better than knobs, especially here in the colder climes where we wear gloves for about four months every year. The ability to cut beyond 45° is helpful, but an exact adjustable stop for 90° is more important.

Table construction

The biggest problem I’ve had with circular saws over the years is bent or misaligned tables. A saw with a damaged table will make rough cuts, will not cut straight and will not adjust smoothly or accurately. The best saw tables are made of a sturdy alloy with reinforcing ribs, and they should be securely fastened to the saw body.

Blade guards

The blade guard on a circular saw needs to swing smoothly out of the way no matter what angle is being cut. It also needs to drop quickly back into place to protect you and your work. The guard needs a good long handle for manual retraction, and it needs to be strong because it’s what the saw rests on most of the time.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Not So Big House

Heat-Shrink Tubing

Milwaukee 18v Cordless Reciprocating Saw (2720)