The sink-mounted soap dispensers in our home get plenty of use. But filling these dispensers is a pain. You either struggle under the sink to retrieve the bottle, or you have to fill them from the top, which isn’t easy to do accurately. So what’s my solution to this dilemma?

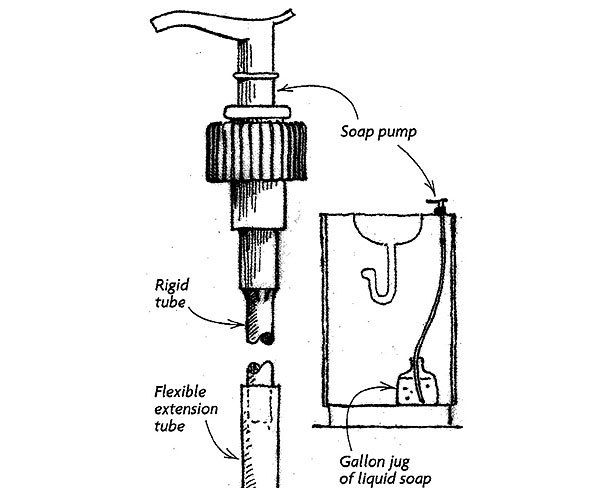

What I’ve done is to toss the bottle and extend the pump’s rigid tube with a piece of clear, flexible hose that reaches into a gallon jug of soap under the sink. I’ve found that 1/4-in. or 3/8-in. I. D. hose works just fine. It should be a snug fit, and so far, hose clamps haven’t been necessary. If the pump’s tube is the flexible variety, use a short piece of rigid copper tubing with an I. D. that matches the tube’s O. D. as a coupling to link the tube with a length of hose. Make the hose as short as possible — 24 in. should do it — and leave the lid off the gallon soap jug so that a vacuum doesn’t form inside it.

Take a peek under the sink from time to time to check the soap level. At our house, a gallon should last, oh, forever.

J. Kaye, Phenix, VA

Edited and Illustrated by Charles Miller

From Fine Homebuilding #145

View Comments

No.

Tried it. Does not work.

@marleyjune Troll much? This is a great idea, if it didn't work for you it's because you did it wrong...

Yes, this does work for I have done my liquid detergent and hand soap this way, but not necessarily the way he designed it. The distance from the reservoir to the pump needs to me shortened so I built a small shelf to hold the bottle of soap and using copper will corrode and cause blockage from antibacterial soap. Use all parts in the correct size vinyl or plastic tubing. If not correct it will not get the vacuum for lift.

I did 3 proposals for the NEC 2020, but because it is a design issue maybe they won’t approve it. I included here, I am using those “tricks” from the 90s with excellent results. Pardon my English as it is my second language but I don’t think with an accent (LOL) . I hope this is the right place for the comments.

1) I proposed to fabricate “Romex” conductors for multi-wiring circuits with red (or other color) circles for the neutrals and the same design for single neutral conductors for conduit runs AND with the existing installations, the electricians must identified those neutrals with a red (or other color) market and install a label on the panel indicating that alteration. Many handymen and homeowners don’t know how to deal with those multi-wiring.

2) I proposed to fabricate extra size protection plates for when a stud is “notched” (not when the middle point is drilled) as many drywallers with the force they do screwing those fasteners, sometimes those sliding as it was a case in one of a projects that I went to fix when the screw slide and hit the neutral in a multi wiring. Btw, that multi-wiring where for appliances, a no-no and it burned the refrigerator. Multi-wiring shouldn’t be use for appliances.

3) Install plumbing insulation (the cheap one) on direct burial Cables or others before filling the trench; it gives extra protection to those. Some people are not carefully, someone filled a trench and instead of using primarily the required sand, he filled it with the dirty and a rock damaged one of the conductor’s insulation.

Regards and nice holidays for everyone!

Louis Duke