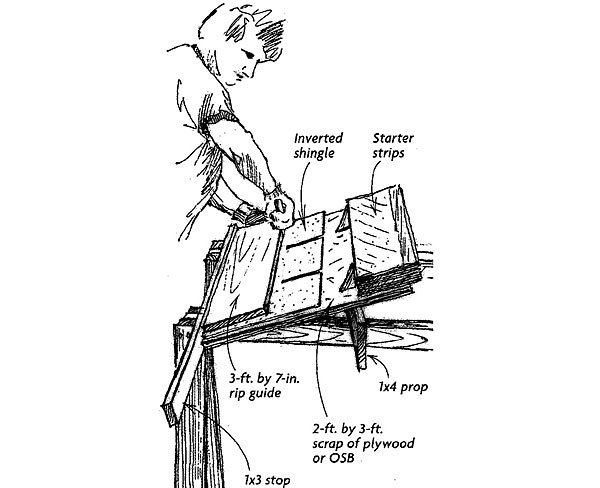

While my brother is framing, roofing, siding or otherwise building something, I’m usually the one who takes care of all the prep and cutting. On a recent roofing job, he asked me to cut several bundles of shingles into starter strips for use along the eave and rake edges. To make short work of the task (and to keep me off my knees), I quickly made a simple cut table. As shown in the drawing, I nailed a 1×3 along the bottom edge of a 2-ft, by 3-ft, scrap piece of 3/4-in. oriented strand board (OSB). With the table set on a pair of sawhorses, I could work with the cut table at a comfortable height. I added a 1×4 prop on the underside to tilt the table for a better position and cut a 3-ft. long by 7-in. wide strip of 1/2-in. OSB as a rip guide for cutting the shingles.

I set a pile of inverted shingles against the 1×3 stop. Then I adjusted the blade on my utility knife so that it just scribed the surface of one shingle when I ran it along the 7-in. guide. I was done cutting the starters in half the time it ordinarily takes me.

I found other shingle-cutting uses for the table, too. By resting a 12-in. triangular framing square (sometimes called a Speed Square) against the stop, I could accurately make repetitive crosscuts for rake starters or trim shingles for ending courses at walls.

We even dragged the table to the roof and hooked the bottom leg over the ridge to have a workstation closer to the action. I’ve tried one of those $350 commercial shingle-cutting tables only once, but I think my little table made of job-site scraps has them beat.

—Bruce Guertin, Coventry, RI

Edited and illustrated by Charles Miller

From Fine Homebuilding #145

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Hook Blade Roofing Knife

Flashing Boot

Fall Protection

View Comments

I buy the roll of starter strip.