Q:

Back when I was a builder, I always installed foil-faced or kraft-faced fiberglass-batt insulation by stapling the face flange to the sides of the stud. Side stapling also is recommended by Bob Killian in his article Putting Fiberglass Insulation in Its Place. Recently, though, I was told that side stapling is a code violation. Who’s right?

Roe A. Osborn, Woodbury, CT

A:

Gene Leger, a home-energy consultant and former building official in Nashua, New Hampshire, responds: When I was code-enforcement officer in Nashua, I banned the side stapling (also called inset stapling) of kraft-paper faced and foil-faced insulation to studs and joists. This widespread practice is a fire hazard as well as a violation of energy and building codes. Here’s why.

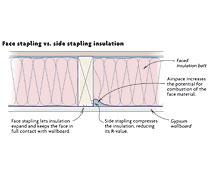

Inset stapling compresses insulation and leaves spaces between the drywall and the insulation. This compression reduces the R-value of both the insulation material itself and the overall R-value of the wall, ceiling or floor in which it’s installed.

Inset stapling leaves channels that provide air paths around insulation. Because gypsum wallboard usually is not sealed to the floor, air can enter at the bottom of the wall cavity. That air then moves up through the channels, resulting in a continuous loop of rising and falling air, which again compromises the effectiveness of the insulation system. Nailing the insulation to the face of the stud eliminates the channel and reduces the chance for air movement inside the stud bay.

An even bigger concern with inset nailing is the potential fire danger. Because insulation affects the development and spread of fire, it is regulated by building codes. Section 723 of 1996 BOCA code, section 707.3 of 1997 UBC code and section R320 of 2000 IRC (International Residential Code) code address the fire rating of insulating materials installed in the walls, floors, ceilings, crawlspaces and attics of a building.

To address fire resistance, all combustible building materials are given flame-spread and smoke-developed indexes. All three model building codes require that the flame-spread index for insulation facings should not exceed 25, and the smoke-developed index should not exceed 450. However, most insulation facings by themselves fail to meet these standards, and the codes make an exception. In type-5 wood-frame construction (typical of most houses), “When these materials are installed in concealed spaces, the flame-spread and smoke-developed limitations do not apply to the facings, provided that the facing is installed in substantial contact with the unexposed surface of the ceiling, floor or wall finish” (IRC 2000, section R320.1).

In other words, the potential for flame spread in insulation is greatly reduced when the facing is in direct contact with the backside of gypsum wallboard, which is the case with face-stapled facings.When the facing is in direct contact, there is little or no airspace to support a fire. But when insulation is stapled to the sides of the studs, direct contact is greatly reduced (and in some cases practically eliminated), and flame-spread potential is substantially increased because of the airspaces created.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Plate Level

Nitrile Work Gloves

Loctite Foamboard Adhesive