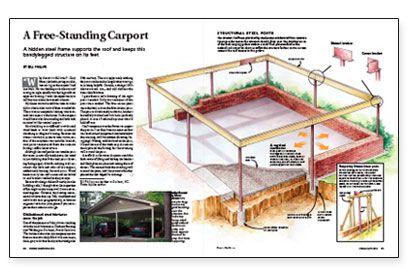

A Free-Standing Carport

A hidden steel frame supports the roof and keeps this bandylegged structure on its feet.

Synopsis: This article describes how to build a roof supported by posts that aren’t reinforced with walls or diagonal bracing; the secret lies in structural steel posts that are vertically cantilevered from concrete footings, a design that keeps this carport from falling over.

Why doesn’t it fall over?” Gary Mazur, the brick-paving installer, was staring at the carport I had just built. He was looking at the heavy roof resting on eight spindly wooden legs with no apparent bracing. I took the opportunity to tell him more than he wanted to know.

My clients wanted a roof over their cars that didn’t obscure the view of their wooded lot. There was no acceptable-looking way to attach the carport to the house. So the carport would have to be free-standing and built with minimal visible vertical support.

Most buildings are stiffened to withstand wind loads or snow loads with structural sheathing or diagonal bracing. Because the owners wanted to preserve their views, neither of these options was suitable. Instead, steel posts cantilevered from the concrete footings stiffen the structure.

Although the roof perches on wooden posts that seem structurally inadequate, the wood is just cladding that hides steel posts. A brick retaining wall surrounds the back and sides of the carport, additionally bracing the steel posts. Wood headers carry the roof trusses and are bolted to steel brackets welded to the post tops.

Because this design did not fit neatly into the building code, I thought that the inspection office might require approval from a structural engineer. However, the drawing was accepted without that step. Still, wind loads and snow loads vary geographically, so have an engineer look over your plans if you incorporate these ideas in a design.

Old-fashioned steel fabricator eases the job

One of the pleasures of this job was working with the steel fabricators, Durham Brazing and Welding in Durham, North Carolina. The brothers who own this company operate from a cavernous shop filled with enormous, dark-gray tools that barely acknowledge the 20th century. There is apparently nothing they can’t make and no lengths they won’t go to in being helpful. Outside, a vintage 1940s delivery truck sits — and still delivers the items they fabricate.

I gave them a scale drawing of the eight posts I needed. Only two variations of the posts were needed. The four corner posts were identical, as were the four interior posts. The posts arrived exactly as drawn, brackets beautifully welded and bolt holes perfectly placed. A coat of red-oxide primer should hold off rust.

I built temporary wooden frames to support the posts as I set their bases in concrete that was hand-mixed and poured into holes below the retaining-wall foundation. Having stabilized and set the posts, I found the rest of the work easy. A concrete truck poured the footing for the retaining wall around the posts.

A scaffold set between the posts eased the back strain of lifting and bolting the headers and flitch plates in place and setting the roof trusses. The masons built the retaining wall around the posts, and the concrete finisher poured the slab sloped for drainage.

For more photos, drawings, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Stabila Extendable Plate to Plate Level

Speed Square

Sledge Hammer