Using Skid-Steer Loaders

Grading a driveway? Leveling a yard? Digging a trench? For under $200, you can rent one of these machines, save a load of money and leave the blisters behind.

Synopsis: An overview of how a skid-steer loader, a simple machine that can be outfitted with various attachments, can save on back-breaking manual labor while being effectively used on the job site. Included are basic operation and safety tips, as well as specific techniques for digging trenches, leveling uneven ground, and grading a driveway.

My enduring memory is of fantastic crashing violence interspersed with brief moments of quiet calm as I watched the world go floating by: sky, trees, ground. The canyon was steep, and the loader rolled and bounced more than 750 ft. before it came to rest against a pile of boulders. The only things that kept me safely inside were the seat belt and good luck, so don’t be surprised if I go on and on about safety.

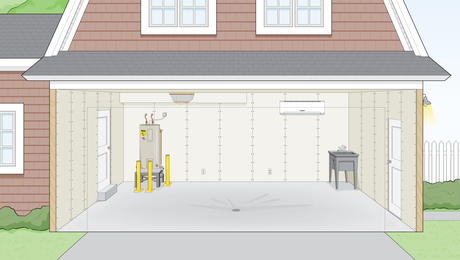

When used carefully, a skid-steer loader (or skid loader as they’re known in the business) can let you get a lot of work done in tight places where you may not be able to get a larger piece of equipment. Just about anyone can learn to operate a skid loader, and because they’re compact and powerful, they can be a lot of fun to use.

A skid loader can be just the right tool when you have too much digging to do by hand but not enough to justify hiring a professional excavator. As a veteran builder, I’ve rented skid loaders many times, and despite that one scary incident (more on that later), I always jump at the chance to use one.

Why is it called a skid loader?

A skid loader’s primary job is hauling loads in its front bucket. The front and rear wheels on each side are tied to each other by a chain drive. There is no steering wheel, and the wheels don’t steer to the left or right. Instead, two levers control steering. The left lever controls the left wheels, and the right lever controls the right wheels. To move the machine, you push the levers forward or pull them back. The harder you push on the levers, the faster the wheels turn. Let go, the levers return to their neutral position, and the wheels stop moving (an important safety feature).

If you push the right lever forward less than the left, the right wheels spin more slowly, and the loader turns to the right as it rolls forward. You can literally turn on a dime by pushing one lever forward and pulling the other back. Because the wheels skid or slide as the machine changes direction, it is called a skid-steer loader.

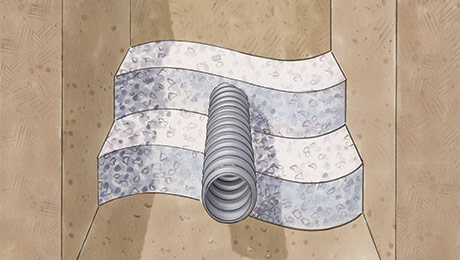

This ability is the skid loader’s chief advantage, but also its chief disadvantage. It can turn around in a small space, which larger loaders and tractors cannot do. But the skidding action can be problematic on some jobs. For example, when preparing for a slab, I wouldn’t use a skid loader to spread sand over a waterproof membrane. The skidding action during turns would dig deep ruts in the soft sand and might tear the membrane.

One machine with many hats

The skid loader is surprisingly versatile. Buckets come either toothed or smooth. In general, a toothed bucket is for digging, and a smooth bucket is for spreading or scraping. Naturally, though, there are exceptions. A smooth bucket digs just fine in sandy loam or damp soil. And a toothed bucket can be helpful for spreading material. Either type of bucket can be removed easily, and attachments can be slipped on in their place.

For more photos, illustrations, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Milwaukee Cordless Tablesaw (2736)

Spyder Stinger Spade Bit

Cadex 18-Gauge Brad Nailer (CB18.50)