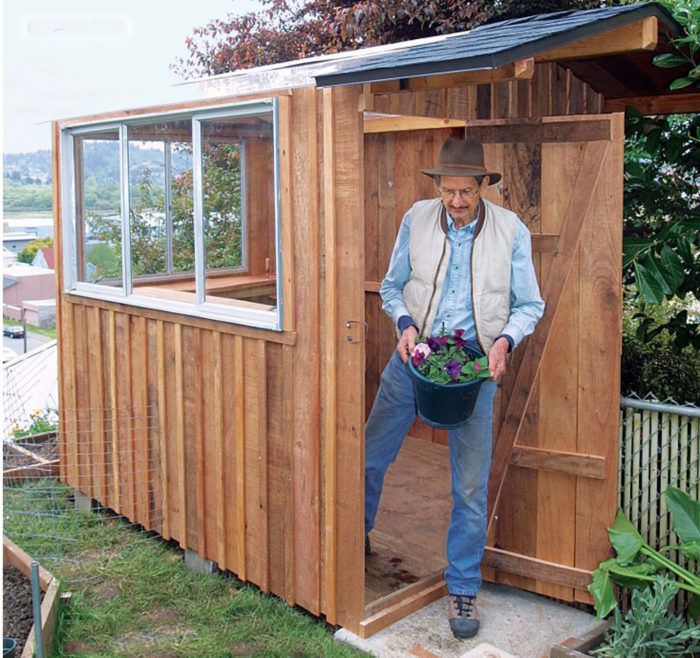

A Recycled Greenhouse

Framer Larry Haun shows how he built this simple garden structure with plank walls made from salvaged lumber.

Synopsis: The author builds a small, attractive greenhouse with salvaged and recycled materials that cost less than $80, using an innovative building technique that eliminates studs.

Years ago, I rented a small house while attending UCLA. That house, like many others in the area, had exterior walls made of 1x boards nailed directly to the platform-framed floor on the bottom and to a single plate at the top, with no studs. Known as single-wall construction, this type of building doesn’t offer much insulation, but it’s strong enough to support a lightweight roof. So I decided that single-wall construction would be perfect for a small greenhouse.

A platform for plants and people

I sited the 6-ft. by 8-ft. greenhouse on the southeast corner of our small lot to catch the warmth of the winter sun. An existing concrete retaining wall supports the greenhouse along one side; I poured a concrete pad for the entry that supports one of the remaining corners.

Support for the last corner comes from defective concrete block rejected by a local supply house. I filled the voids in the block with concrete left over from the entry pad. A strap embedded in the pad helps to secure the platform.

Once the piers were in place and level, I built the platform from pressure-treated 2x4s with the help of my brother Joe and my friend Clyde. After measuring across the platform diagonally to square it, we sheathed the joists with treated plywood to resist mold and rot. But rather than the toxic treated wood (CCA), we used the newer, less toxic wood (CBA) treated with borate.

Walls from salvaged pallets

A nearby plywood plant sells 4-ft. by 8-ft. pallets for $2 each. I bought 10 pallets made of 1x mahogany boards, knocked them apart and ripped the boards into 6-in. widths. I also ripped a pile of 1 ⁄2-in. by 2-in. battens and bathed all the wood I’d cut in linseed oil.

Single-wall construction starts with the corners. I cut four boards 82 in. long and beveled their tops at 14° to match the 3-in-12 pitch roof I planned. We screwed one of these boards to each of the corners on the long sides of the platform. Next, I cut a 14° angle on the tops of four more boards, and we screwed each of them to one of the first boards with coated fast-tap screws to form the corners.

For the top plates on the 8-ft. long walls, I bought two 10-ft. 4x4s and cut a 14° bevel on the top edge. We screwed the 4x plates to the tops of the corners, letting the plates cantilever 2 ft. for a porch on the door end. Recycled 2x4s tie the 8-ft. sides together and act as top plates for the 6-ft. long gable walls.

For the ridge, I beveled the top edges of a 10-ft. 4×6, supporting it with a short vertical 2×4 resting on the gable walls’ horizontal 2x4s. Measuring 36 in. down from the top plate, we attached flat 2x4s between the corner boards for a rough windowsill, which also gave me a cleat for the planting tables inside.

For more photos and details on this recycled greenhouse, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Stabila Classic Level Set

Guardian Fall Protection Pee Vee

Magoog Tall Stair Gauges