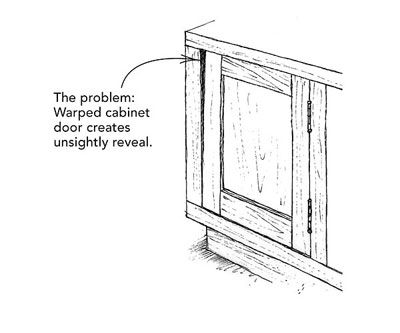

A warped cabinet door can be a real pain. When you have spent hours matching panels, colors and grains, the last thing you want to do is remake a door. My approach takes a couple of hours and $5 in materials. In essence, I make a U-shaped spring, or torsion bar, out of music wire and insert it into the door. Music wire is commonly available in hardware stores. It is much stiffer than regular mild-steel rods.

The first step is to lay out for drilling into the end grain of the stiles to miss any hinges or other hardware. Once you have the centers laid out, wait on the drilling until the torsion bar is made. If the distance between the steel legs varies a bit, you can shift the holes accordingly. It’s easier to make the holes match the steel than to try to bend the steel to an exact dimension.

To make the torsion bar, you need music wire and a torch (ordinary propane torches really don’t work; MAPP gas or oxyacetylene are the best choices). For a 3/4-in. thick cabinet door, I recommend using 3/16-in. music wire (drill the holes 1/4 in.; otherwise it’s too much of a struggle to fit the spring). Clamp the wire in a vise, leaving the leg long (7 in. to 8 in.). Bring the wire to an orange heat, and with pliers, bend the leg to a 90º angle. Finish the corner with a light hammer blow or two to square it up, and let it cool slowly. Don’t chill or quench the bend. If you do, the steel will become brittle and can snap.

Using the dimension from the layout marks on your door, locate the bending point for the opposite leg. Now for the fun part. The idea is to offset the legs from each other so that when they are inserted in the door they twist against the warp. Bend the second leg offset to your best guess. Then, using a Dremel tool or grinder, cut off the legs to fit the depth of the holes you will drill in the stiles. Don’t try using a bolt cutter on music wire unless you really want to buy a new one.

Now bore the door, using a doweling jig and a bell-hanger bit (available at most hardware stores). For a typical door, I bore in about 5 in. to 6 in. to provide the leverage required; with careful drilling, you can get this far fairly easily, even in a thin door. For thicker doors, you can use thicker wire or more offset as required. After boring, I use a router and a splining bit to rout a channel between the holes for the middle section of the torsion bar. Slip it in for a test fit, with a tape loop or string underneath to pull it out. The door may fit on the first try, or you may need to increase or decrease the spring tension by heating and rebending. A dab of hot glue or epoxy will hold the spring in place. If the door shifts again after a bit of time, you can remove the spring and adjust it.

Gregg Roos, San Francisco, CA