For lubricating screws before driving them home, I’ve used them all: bar soap, liquid soap, wax, even sweat. I’ve also sheared and stripped the heads off more than my fair share of screws.

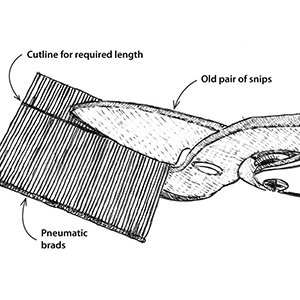

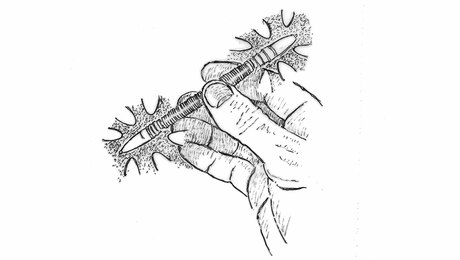

Recently, I was installing some oak faceframe kitchen cabinets, and when it came time to screw the cabinets together, I looked in my drill case for the bar of Ivory soap. It wasn’t there. Rummaging around, I spied a roll of Teflon plumbers’ tape, and on a whim, I wrapped the tip of a #8, 2-1/2 in. coarse-thread screw with two or three twists of tape. I inserted it into a 1-1/4 in. deep countersunk hole and ran it into the adjacent cabinet. It went into that oak like Sherman through Atlanta. When it came time to mount the cabinets to the wall, I wrapped the factory-supplied #10, 2-1/2 in. pan heads the same way.

I prebored the back of the cabinets and screwed them to the framing—rock-hard Douglas-fir studs—without any pilot holes. I didn’t shear one shaft or strip one screw head. It took several minutes to prepare the screws, but the aggravation avoided is worth at least a couple of cups of coffee on the other end.

Peter Klebaur, Mountainside, NJ

Edited and Illustrated by Charles Miller

From Fine Homebuilding #153

View Comments

Do you mean 'twists' or 'turns'? Just how much of the screw is the 'tip'? I think I need a picture...

Many years ago an old carpenter told me never to use soap to lubricate screws because it was hydrophilic(loves water) causing the screws to rust out. Use wax because it is hydrophobic(repels water).

Obviously you haven't been around Douglas fir much. There's no such thing as "rock hard", in our neck of the woods it's pretty soft. The last thing we do is waste time using any kind of lubricant to get a screw in it.

Wrapping Teflon tape around the end of several screws could be a bit tedious, but how about dipping them in Teflon pipe dope? Not worth the effort for most situations, but as an alternative to pre-drilling, might be worth it sometimes.