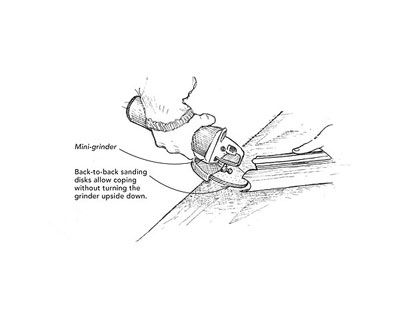

My mini-grinders see a lot of action on-site, and nothing beats them for coping moldings. Instead of using the backing pad, I put a pair of disks back to back: one with the grits facing up, and the other with them facing down. I sandwich the disks between the two clamping nuts that normally hold grinding disks or cutoff wheels. This arrangement lets me cope the whole profile of a molding without turning over the grinder. I can cut to the left or right, and the dust keeps heading away from me. Between the stiffness of the doubled-up disks and the centrifugal force, the disks stay flat while cutting. Another use for the top disk is removing extra material from the bottoms of casings so that flooring will slide under.

Gregg Roos, San Francisco, CA