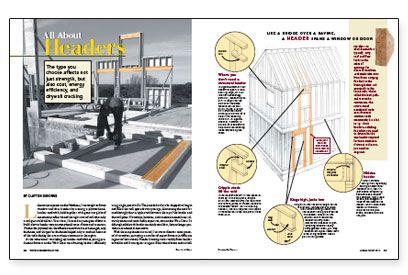

All About Headers

The type you choose affects not just strength, but also cost, energy efficiency, and drywall cracking.

Synopsis: Everything you ever wanted to know about headers. The author explains the pros and cons of nine types of traditional headers. Find practical alternatives which will save you time and labor, but still carry the load. Choose which header is right for your job, then learn how to install it and protect it from common problems such as condensation and shrinking. The author also provides useful guidelines for determining header heights for custom doorframes.

Like many carpenters in the Northeast, I was taught to frame window and door headers by creating a plywood-and-lumber sandwich, held together with generous globs of construction adhesive and the tight rows of nails that onlya nail gun could deliver. Years later, I learned my energetic efforts to build a better header were an exceptional waste of time and resources. Neither the plywood nor the adhesive contributed much strength, only thickness, and this perfect thickness helped only to conduct heat out of the walls during the severe winters common to the region.

At the same time I was laying up lumber sandwiches, young production framers on the West Coast were framing headers efficiently using single-piece 4x12s. They needed only to be chopped to length and filled the wall space above openings, eliminating the need for maddeningly short cripple studs between the top of the header and the wall plate. Nowadays, however, such massive materials are relatively scarce and remarkably expensive, even on the West Coast. So although solid-stock headers certainly save labor, they no longer provide an economical alternative.

With these experiences in mind, I set out to discover some practical alternatives, surveying a number of expert framers in different regions of the country. Header framing varies widely from builder to builder and from region to region. Even when factors such as wall thickness and load conditions are made equal, building traditions and individual preferences make for a wide range of header configurations. The examples shown here are just a few of the options possible when you mix and match features, notch cripple studs, and sift in engineered materials. But they aptly demonstrate a number of practical considerations that must be kept in mind when framing a good header.

Big headers need more studs

A header transfers loads from the roof and floors above to the foundation below by way of jack studs. This means the header not only must be deep enough (depth refers to the height of a beam: 2x10s are deeper than 2x6s) for a given span to resist bending under load, but also must be supported by jack studs on each end that are part of a load path that continues to the foundation.

The International Residential Code (IRC) specifies not only header size but also the number of jack studs for most common situations. While most windows and doors require just one jack stud at each end, long spans or extreme loads may call for two or more jack studs to increase the area bearing the load. If the loads on any header are concentrated over too small an area, the wood fibers at the ends of the header can be crushed. This can cause the header to drop, which in turn can crack drywall or, particularly with patio doors and casement windows, cause the door or window to jam.

Header hangers, such as the Simpson HH Series (www.strongtie.com), can be used to eliminate jack studs altogether. I’ve used them in some remodeling situations when I needed to squeeze a patio door or a wide window into an existing wall that didn’t have quite enough space for double jack studs. One jack and a SimpsonHH Series hanger did the trick.

For more photos, drawings, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Protective Eyewear

Leather Tool Rig

Stabila Extendable Plate to Plate Level