Cantilevered Deck Step

Learn how to cantilever steps for a deck without the need for cutting stringers or extensive concrete work.

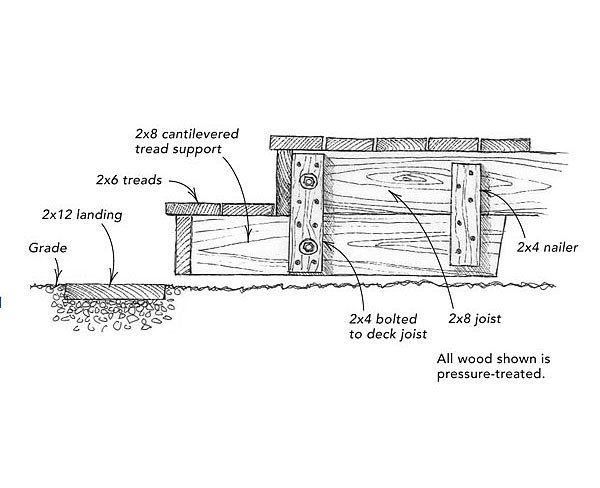

Now that it has been in service for 14 years, I think it’s safe to say the cantilevered step from my deck to the yard is a workable idea. I came up with this method because I didn’t want to bother with any more concrete work or cutting stringers from 2x12s. As shown in the drawing, I hung cantilevered treads from adjacent deck joists by way of short pieces of 2×4.

The connections closest to the treads are a combination of deck screws and 1/2-in. machine bolts because this is where the most loading occurs when you step on the tread. The far end of the 2×8 tread support acts like a lever, pressing upward against the bottom of the deck joist. For this reason, the inboard connection doesn’t need the extra shear strength of the machine bolts. This method worked so well that I used it on the other end of the deck where the sloping grade required six risers. I just stacked one 2×8 below the next, in the same structural assembly shown here.

—Dan Lebeau, Berwyn, IL

From Fine Homebuilding #164

RELATED STORIES

Got a Tip?

Do you have any great tips like this one on how to cantilever steps for a deck? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at tips@finehomebuilding.com, or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Angel Guard Deck Demon

Metal Connector Nailer

Standard Marking Chalk

View Comments

I don't care for the look of two chunks of 2x4 showing on the outside of the deck. I would glue and staple plywood on the inside of the deck where it wouldn't show.

Mr. Lebeau, I Agree with nailbender123 but "DO You" Really use "Your METHOD" on the "6 RISER" Steps on the "Other SIDE" of your "Deck"?

HOW "Wide" are your "STEPS"? How MANY (Excuse ME?) rather "Heavy People" Might Be standing ON the 6-Steps on the OTHER SIDE of your "Deck"?

I "Agree" with nailbender 123, "I Would" use Plywood on the "Inside" of ANY "Steps" but; 6 Steps on the "Other Side"???

I would "USE" a couple of 4X4's Cemented into the Ground for the "6 Steps" on the OTHER SIDE of "Your Deck"!

Way to go, Lebeau!

Some years ago I was planning to do the same thing but it turned out that we needed 5 steps and I didn’t want to risk problems during final inspection.

My inclination is to think the six step stair might be a little springy, but we don’t know how far back along the floor joists the 2x8’s go and all the connection details. In any case, if load and springiness problems did come up, they’d be pretty easily cured – just put some concrete pavers under the toe of the stair. If you get settlement or frost heave, it's easy enough to adjust the pavers. A level paved surface at the bottom of a deck stair is a pretty good safety measure anyway – just imagine what happens when somebody comes down the stair and steps on sloping wet grass.

As for the 2x4 scabs bolted on to the deck joists and 2x8 tread supports, I’d be a lot more comfortable with that than with hidden plywood exposed to water dripping down between the stair treads. Thinking along the lines of deck esthetics, there are a lot bigger fish to fry than some bolted-on 2x4’s.

My hat goes off to Lebeau. He seems to have the guts to disregard convention and the flexibility to think outside the box.

IMO since it's a "thing" in building to show structural ties, supporting members etc, make the scabs on the side look like they are an intended feature instead of an afterthought by using the same bolts on both, beveling the edges, making them the same length and using 2x6 or even 2x8 to draw attention to them. Whatever works!

I'm tired of my home insurance increasing each year because of foolish people in society. There's a building code for a reason. Really? This tip is an example of "Fine Homebuilding? Don't get me going on deep fat frying in an open pot on the stove or a turkey on an open pot on the BBQ (near the house).

If I'm reading the drawing correctly, there are two issues:

1. The cantilevered step will be 9.5" which is outside of building code standards. (7.5"+1.5"+.5" *of assumed float* = 9.5" step)

2. The rise of the tread will vary and won't pass code. The first rise is 9.5" and the next would be 7.5", which is on the tall side of acceptable. The 2" variance is not acceptable.

In regards to the other comments about the 2×4 nailers being on the outside of the deck, I sure hope they would be on the inside of the deck and the only thing you'd see from the outside would be a countersunk bolt head.

Here's a pretty cool video on how to build stairs without stringers:

https://youtu.be/DAjEzZ6nO6U

I'm with "Suburbanguy", do the work, and do it right...or hire someone who can. You think you're the only one who's had to deal with frost heave, or grassy slopes. Dig down below frost depth and go from there. You're not doing your customers any favors by cutting corners, or the person that buys your house. You really think you've saved time and money with this process? You need to go back and do the math. How something like this gets into "Fine" Homebuilding needs to be reviewed...not only is this a gobbled up mess, there isn't an inspector that knows anything about Building that would approve it. It would seem to me someone decides to build a half dozen steps based on the information provided here...2, 3, or more people get seriously injured due to the construction of the steps...FineHomebuilding would have some liability.

I design cantilevered stairs for inspected construction. I detail and calculate per code on the plans and get and approved stamp. It sometimes takes a round of comments and revision. Mr Lebeau's scheme looks good to me, but I usually need more height. The simplest way is to use a solid stringer, redwood or ptdf and Simpson stair angles and thick treads that can span the width without a center stringer. With 4x6 treads the risers can be open and meet the code with less than a 4 inch opening. I set the top tread level with the deck which is structurally convenient and lets the top nosing match the others. The stairs are then an extension of the building and the lower landing part of the landscape.