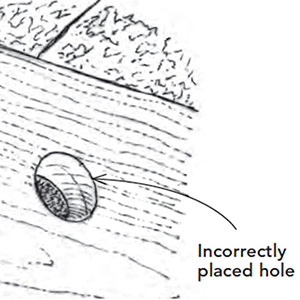

When I need to bore an especially clean hole, such as one for a screw plug, I typically apply the simple principle of opening up my wallet; I use pricey, precision-machined brad-point drills that I normally can count on for crisp work. But with certain woods, such as mahogany, even the sharpest cutters leave an unsightly frayed edge. Up-shear geometry is great for evacuating shavings, but it can drag debris past the surface fiber, causing splintering. Here’s a way to avoid the problem.

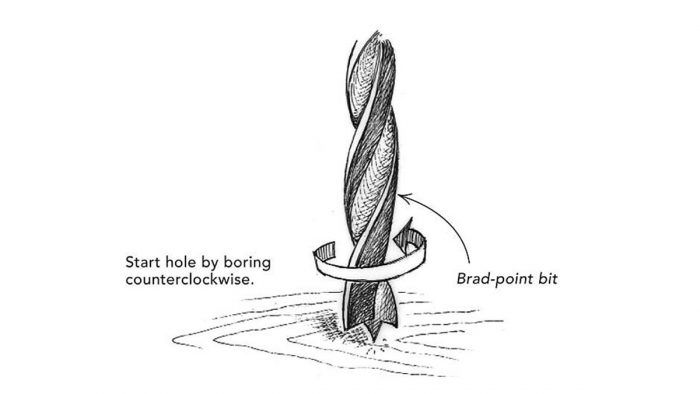

As shown in the drawing, start the hole with the driver/drill running in reverse to produce down-shear cutting, which pushes the waste wood away from the face of the workpiece while compressing surface fibers at the circumference of the hole. Finish boring with the driver/drill rotating normally.

Unless you use a drill press, the hole will likely be 1/64 in. or so out of round. In all but the fussiest of circumstances, this amount will be negligible. If this method is new to you, try the technique on a few pieces of scrap to get a feel for it.

—Michael Standish, West Roxbury, MA

Edited and illustrated by Charles Miller

From Fine Homebuilding #166

View Comments

Never heard of a Forstner bit?

This article is from October, 2004. Forstners were pretty well known way before that.