Protect a Concrete Pier Foundation From Frost Damage

An expert shares two main principles for ensuring a solid and durable foundation pier.

Question:

I’m building a cabin in northern Maine, and I plan to set the framework on concrete piers formed with cardboard tubes. I’ve heard of frost-heave problems associated with this system, but I don’t want to dig a foundation for the cabin. How can I combat the effects of frost?

Chuck Clark, None

Answer:

Lynn S. Hayward, president of Hayward-Robertson Builders Inc. in Camden, Maine, replies: We’ve seen some problems with concrete-column construction in northern and central Maine, but this system can be great if you do it right. The problem is that as frozen soil heaves in the winter, it can grab a cardboard column and cause it to lift or to shift slightly. When the ground settles back, the column can be left tilted. Even if you peel off the cardboard, frost is good at grabbing concrete.

During the 30 years that I’ve been building in Maine, I’ve developed a number of ways to avoid frost-induced problems with column construction.

There are two main principles:

- Control frost action as much as you can.

- Give the frost something to grab so that it leaves the column alone.

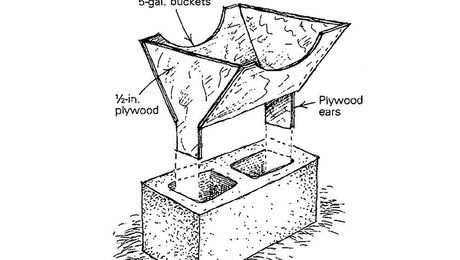

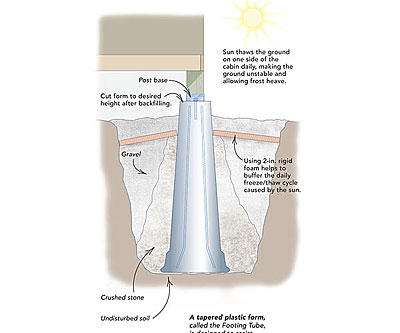

As shown in the drawing, you can keep frost action low by backfilling around a column with crushed stone and gravel; this process helps to drain water away from the column. You also can buffer the ground temperature with foam insulation. Columns on the south side of a foundation experience more freeze/thaw cycles than those on the north side because the sun beats on them during the day. A layer of insulation will keep the sun’s heat out of the ground.

To keep frost from grabbing the column, I use a sleeve. In the old days, I used schedule- 20 sewer pipe as a sleeve. The frost would grab the sleeve, but the column itself would not move.

When pressure-treated wood became widely available, I poured a concrete footing below the frost line, then ran a pressure-treated post to the footing and wrapped the column with plastic sheeting up to ground level. The plastic acted as a sleeve so that the frost couldn’t grab the wood.

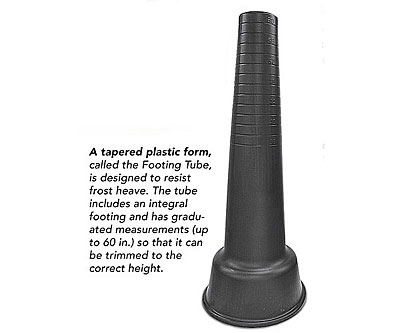

There’s a product that incorporates the footing, pier, and frostproof sleeve all in one. It’s called the Footing Tube (www.foottube.com). Rather than cardboard, the tube is made of high-density plastic, so frost can’t bond to it. The footing base is built in. All you need to do is set the form in a hole, cut off the top to the desired height, backfill, and pour concrete.

Below are helpful tips if you decide to use Footing Tube to Build a Concrete Pier Foundation

1. Make sure your concrete piers are deep enough.

Find out the depth at which the soil freezes (the frost line), and ensure the concrete footing extends at least a foot below that. The footing should also be at least 8 inches thick and twice the width of the wall it supports.

2. Get your footings right.

When the footings fail, the result is catastrophic. Code tells you what to do; we have some resources to show you how.

3. Wait at least seven days for the concrete to cure before you build on it.

Concrete continues to cure long after you pour it, reaching its top strength at 28 days. Waiting at least seven days will reduce the risk of cracking. If you don’t wait for the concrete to cure, the result will be a water deficiency that greatly reduces the durability of the concrete and costs a lot of money and time down the road.

RELATED STORIES

- The Right Footings for Strong Foundations

- Three Types of Footings to Support Foundation Walls

- How to Set Anchor Bolts in Concrete Piers

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Smart String Line

Anchor Bolt Marker

Plate Level