I always drain my compressor at the end of the day so that water doesn’t stand in the tank and the hoses aren’t endlessly under pressure. I installed an automatic drain valve in the tank, which opens when the pressure drops to less than 8 psi. That takes care of the water. The issue is how to bleed the air gradually, without the hose whipping around or emitting great blasts of air that scare the dog.

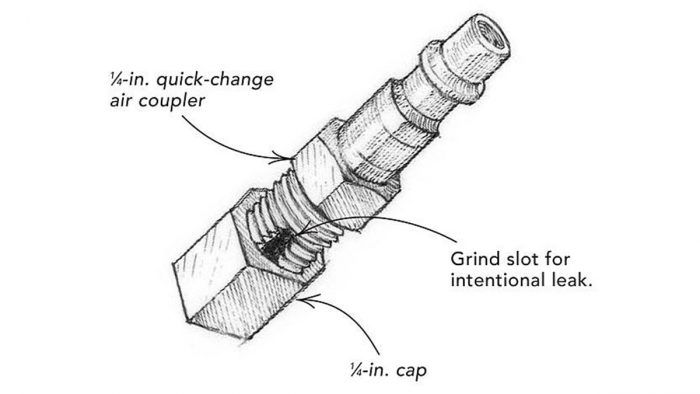

The drawing at right illustrates a little gadget that I devised to solve the problem. It’s a quick-change air coupler with a notch ground into its threaded nipple and a 1/4-in. threaded cap. The cap covers most of the coupler’s threaded nipple, but not the slot ground into the side of the nipple.

At the end of the day, I uncouple my nail gun from its hose and pop this gadget into its place. In about 20 minutes, the 22-gal. tank is no longer under pressure, and any moisture is free to evacuate.

Stephen Miller, Oakland, CA

Edited and Illustrated by Charles Miller

From Fine Homebuilding #169

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Handy Heat Gun

Reliable Crimp Connectors

Affordable IR Camera

View Comments

What about the water still at the bottom of the tank that has accumulated from the day's work?

As BurbGuy suggests, I have yet to see a compressor that was actually designed to expel the condensed water without tilting the tank this way and that. Seems like an obviously desirable and not very complex feature. Drain design always seems like an afterthought- bad positioning, bad accessibility, clumsy operation- strange in a feature that's basic to good maintenance.

I'm on my second compressor in 23 years, and I rarely think to drain the tank. The motor burnt out on the first before I had any leaks. It's just never been an issue for me, even though I live in a sub-tropical climate.