Handsaw Revival

Today's handsaws cut all kinds of material with renewed comfort, control, and durability.

Synopsis: An overview of traditional and contemporary saws, this article will help you know which tool to use on wood, metal, and plastic. You’ll find a detailed discussion of tooth designs, along with photos of more than a dozen saws.

If you’re trimming an entire house and you don’t have a power miter saw, you’re crazy. But if you think handsaws are old fashioned, you’re wrong, although you’re probably not alone. Even in an age of laser-guided power tools, saw manufacturers continue to improve and reinvent the handsaw.

Purists might argue that their 100-year-old Disston handsaw will outperform any new saw. They’ll laugh at the quality of modern saws and complain that new saws are throwaway tools because many of them can’t be resharpened. In many ways, they’re right. A well-maintained Disston crosscut saw makes easy work of cutting through most wood. And when the blade dulls, it can be filed and set to cut as if it were new. Of course, you have to know how to file and set the teeth, and if you’re cutting particleboard or other man-made products, the glue may dull the blade faster than you can sharpen it.

Modern handsaw design is a response to the evolution of home building. Handsaws are used less, and sharpening is a lost art. Today’s handsaws are designed to cut modern materials easily and without dulling.

Beyond basic crosscut saws and ripsaws

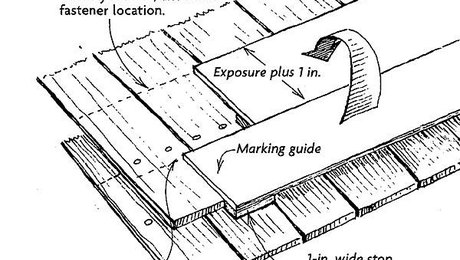

Once there were two standard saws used by carpenters, one for crosscutting and one for ripping. Because most ripping now is done with a circular saw or on a tablesaw, ripsaws are a dying breed. Many new handsaws are capable of both crosscutting and ripping. Marketed as general-purpose saws, they are designed to cut solid lumber, engineered wood, and other man-made materials. There are also some innovative handsaws designed to cut specific materials such as drywall, composite decking, and synthetic trim.

Traditional Japanese handsaws also have influenced the evolution of modern handsaws. The most notable difference between a Western-style saw and a Japanese handsaw is that the Western saw cuts on the push stroke and the Japanese saw cuts on the pull stroke. Japanese saws have inspired manufacturers to rethink both the blade and handle design of their saws.

Different strokes for different folks

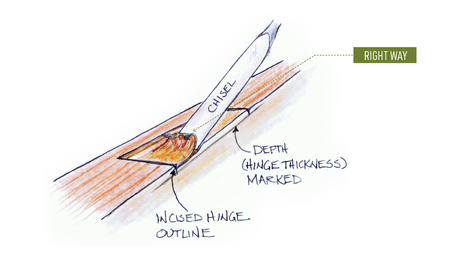

Traditional Western crosscut saws cut on the push stroke. The tips of the teeth score the wood, and the edges of the teeth sever the wood fibers. Western-ripsaw teeth also cut on the push stroke, but the teeth work more like a series of chisels. The teeth on both types of saw are set alternately so that the kerf—the groove created by the saw—is wider than the blade, reducing friction as the saw moves deeper into the cut. Cutting with a Western-style saw requires sharp, properly set teeth and good technique because the blade has a tendency to bend during cutting (see “Building Skills” from this issue, “Cutting With a Handsaw”).

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

All New Kitchen Ideas that Work

Hitachi Pin Nailer (NP35A)

Milwaukee Compact Cordless Router (2723-20)