Control vs. Isolation Joints in a Concrete Driveway

The choice depends on whether the joint is separating two different building elements or dividing one large one.

Q:

What’s the best way to pour a concrete driveway: with expansion joints cut into the concrete after it has cured, or with isolation joints integrated into the forms?

John Zimmerling, Hendersonville, TN

A:

Paul Fisette, director of the building-materials and wood-technology program at the University of Massachusetts, replies: Isolation joints typically are used where different building elements meet, such as where a horizontal slab meets a vertical wall. Control joints, or expansion joints as you call them, are better for driveways.

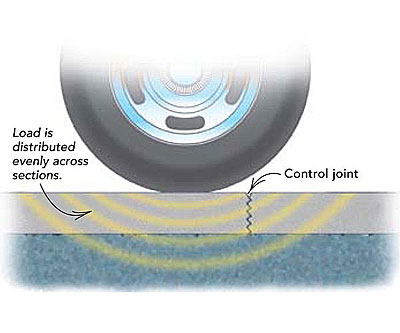

Control joints are a deliberate plane of weakness placed in the slab, either cut with a concrete saw or formed with a jointer while the concrete is still wet. Spaced every 10 ft. to 12 ft., control joints don’t go all the way through the concrete; they just extend about one-quarter of the slab’s thickness. As the slab shrinks, it cracks along these predetermined lines (see drawings).

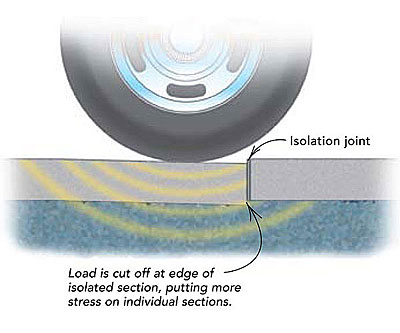

Control joints should transfer loads perpendicular to the surface of the slab. Typically, the cracks that develop as the slab shrinks follow the cement paste in the mix, and the aggregate particles from each side of the crack are still somewhat interlocked or knuckled together. This knuckling provides some load transfer between slab panels so that concentrated loads are not at an edge of a panel. Because they break continuity between panels, isolation joints don’t have the load-sharing capacity of control joints.