Synthetic Decking Takes Off

Now available in a variety of colors and textures, this durable array of products won't rot, splinter, or crack. What's not to like?

Synopsis: More than 60 manufacturers now produce synthetic decking products. Some look amazingly like real wood. This article looks at the pros and cons of these wood alternatives, explains the three basic types of synthetic decking, and illustrates some of the hidden fastening systems used to secure deck planks.

It wasn’t that hard to persuade Atlanta-based deck builder Donnie Miller to switch to synthetic decking. “Deep down, everyone likes wood,” Miller says. “But most people aren’t willing to do all the maintenance that keeps a wood deck looking good.”

Synthetic decking certainly provides a no-maintenance alternative to wood. Until recently, though, the limited variety of synthetic-decking colors and styles has been a turnoff for many designers, builders, and homeowners. No more. Today, more than 60 different brands of synthetic decking are available, with an impressive selection of colors, textures, and styles.

Cost is still an issue

The major objection to man-made decking is cost. Depending on the synthetic decking you choose, costs range from 2 to 5 times that of pressure-treated wood. Bear Board, one of the least-expensive brands of synthetic decking, costs around $1.89 per lin. ft. At the high end, you can pay up to $5 per lin. ft. for vinyl-decking boards.

When synthetic materials are viewed as part of a complete job, however, costs are more in line, averaging 25% to 50% more than a pressure-treated wooden deck, depending on your choice of materials.

Consider appearance, availability, and installation details

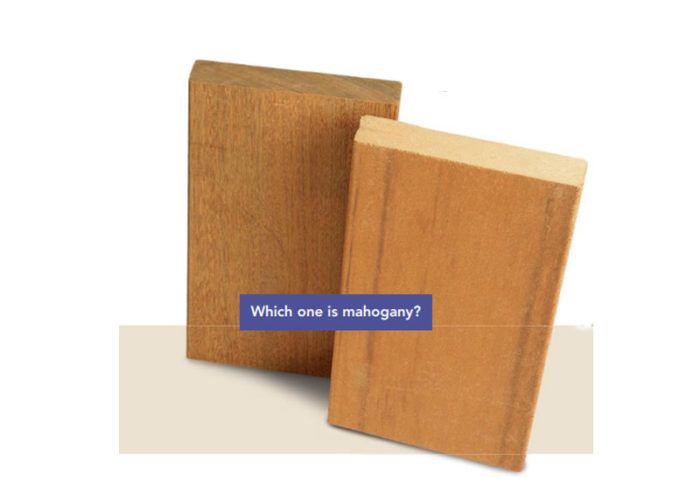

Once you get past the cost of these new man-made decking products, appearance is likely to be the biggest factor in what to choose. A world of color beyond the wastepaper gray of the early 1990s now is available. Many products come in four colors, Trex’s Brasilia decking resembles exotic hardwoods. Textures range from smooth to coarse wood-grain patterns. Some, like EverGrain and Procell, are more convincing than others. Accessories such as handrails, balusters, trim boards, and moldings are common.

There is one other subjective aspect of appearance to consider: the way a particular decking matches your house. Some are smooth, others rustic, and still others look like plastic. Your house will provide clues about which direction to go.

Once you find what you like, you have to make sure you can get your hands on the product. Even though more than 60 U.S. companies now are making various synthetic-decking products, local access to more than a dozen of these products is unlikely. Most lumberyards and home centers stock no more than a few brands. To get a less popular brand, you can order directly from the manufacturer, but you’ll pay extra for shipping.

The news about installation details and workability of synthetic decking is mostly good. Ordinary carbide-tipped cutting tools easily cut and shape these highly consistent materials. Contractors prefer working with composites over wood because there’s no waste due to material defects. One downside, however, is weight. Some of the composites approach 3 lb. per lin. ft.

For custom-routed edge profiles, you must buy solid decking. Hollow or ribbed decking, which is usually thinner and lighter, can’t be milled to create custom profiles, so end caps and channels are used as edging. A range of readily available hidden and other fasteners installs at least as quickly as they do in wood.

For more photos and details on synthetic decking, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Metal Connector Nailer

Lithium-Ion Cordless Palm Nailer

FastenMaster Screw Bolt Fastening System