When I need to cut a tapered piece of lumber, I reach for the jig shown in the drawing. This jig is designed to run straight against the tablesaw’s fence while securely holding a workpiece that can be clamped at an angle not parallel to the fence. The jig allows me to cut an accurately tapered piece of lumber or put a straight edge on a workpiece with crooked edges.

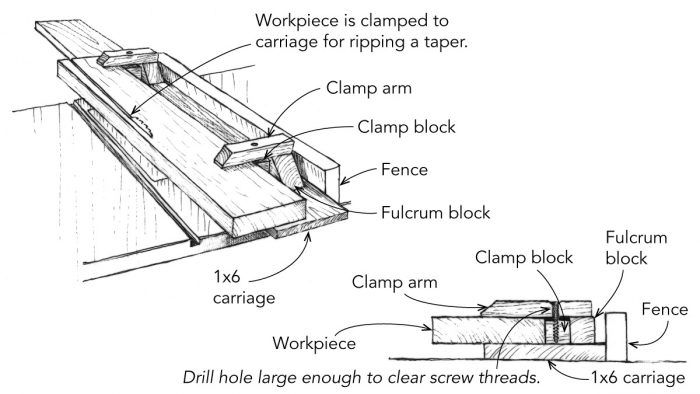

The jig consists of a 1×6 carriage, chosen for its straightness, and a couple of pieces of 2×2 for the fulcrum blocks and clamp blocks. There are no critical dimensions, except that the clamp blocks must be a bit shorter than the fulcrum blocks. Both are fastened securely to the carriage with glue and screws.

Each fulcrum block supports a clamp arm, which extends beyond the clamp block to bear on the workpiece. A screw driven through the clamp arm into the clamp block supplies the clamping power. It’s important that the screw turn freely in the clamp arm, so I drill a hole in each one that is large enough to clear the screw’s threads.

For use, the workpiece is simply inserted under the ends of the clamp arms, and the screws are tightened into the clamp blocks. The screws should be long enough to hold securely in the blocks. Also, take care to make this rig sturdy enough so that it doesn’t come apart at a crucial moment.

Wayne Galvin, Chehalis, WA

Edited and Illustrated by Charles Miller

From Fine Homebuilding #172

View Comments

I use a little different method to cut a taper. I took a nice straight hardwood 1x6x8. on one side near end of the board I screwed in a flathead screw flush to surface. Then at the end of the board I have a small leg sticking out towards the piece being cut. This pushes the board to be tapered when the hardwood board is ran against the saw fence. The screw is backed out the amount of taper I need. I set the fence width at the other end of board to be cut at the wide end of taper width. I've been using this method for years. Fast and simple.