Stair-Stringer Stress Relief

Ensure your stair stringers are strong using this simple trick.

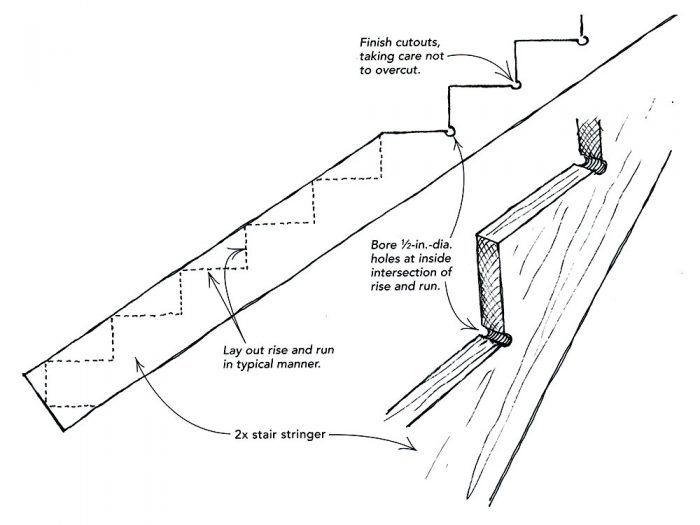

I’ve cut a lot of stair stringers out of 2x stock over the years, and experience has taught me to be careful when cutting out the triangular pieces that create bearing surfaces for treads and risers. If the sawcut goes even a little bit beyond the intersection of the rise and run, it can create a weak spot that either can weaken the stringer or can cause one of the ears that support the treads to fall off if it is bumped during installation. The drawing shows how I avoid the problem.

After marking the layout for rise and run, I bore 1/2-in.-dia. keyholes where the backs of the treads and the bottoms of the risers are to meet. Then I use a circular saw to make the bulk of the cuts, stopping short of the holes and finishing the cuts with a jigsaw. The keyholes provide stress relief, minimizing the chances of a sawcut-induced crack weakening the stringers. I’ve been using this technique for the past 12 or so years, and the method hasn’t failed me yet.

— Michael Standish; West Roxbury, MA

From Fine Homebuilding #174

RELATED STORIES

- Build Like a Pro: Precision Stair Stringers

- How To Cut Stair Stringers

- Straight, Strong, Precision Stair Stringers

Got a Tip?

Do you have any great tips like this one on how to prevent stair stringers from weakening? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at [email protected], or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

View Comments

Good info, thanks Mike.

Good info, indeed.

I'm going to install some 1" x 12" x15' skirtboards on an interior staircase before risers, and treads. I'm going to use this info upside down.

I plan to prefinish them before I make my cuts to minimize handling them.

They're going to be fragile enough after cutting, and this will help.

I'll have a bit of play with the treads, but not too much with the risers.

Thanks!

I started doing this exact thing a few years ago on deck stairs; I figure when two guys in different parts of the country come up with the same idea, there's probably something to it. Worth noting, I have also started doing this for deck joists, when there is a check on the end, that I can't cut off, because I need the length. I find the end of the check and drill a nice round hole there to hopefully stop the check from advancing.