Q:

How do I solder pipe to a ball valve with a nylon seat without destroying the nylon?

Jim Tandy, via email, None

A:

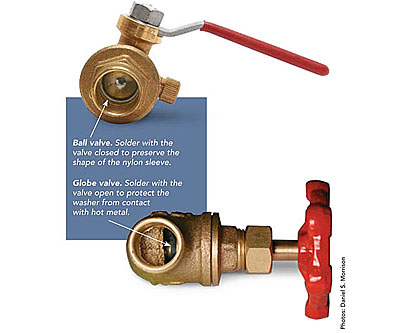

Ed Cunha, a plumber in Brewster, Massachusetts, replies: Three types of valves typically are used in residential-plumbing systems: ball valve, gate valve, and globe or stop valve. Each has an integral washer or seat that can be damaged by overheating during the soldering process. Depending on the type of valve used, you solder with the valve either open or closed.

Ball valves have a nylon seat and should be soldered with the valve closed. This procedure allows the seat to keep its shape as it heats up. If a water or steam problem exists, I open the valve just a crack to allow the steam to escape. Then I close the valve as soon as the solder hardens.

All other valves should be soldered with the valve open. This protects the washer from melting by removing it from contact with the metal valve body. Always let the valve cool completely before opening (again, to protect the washer from contact with hot metal).