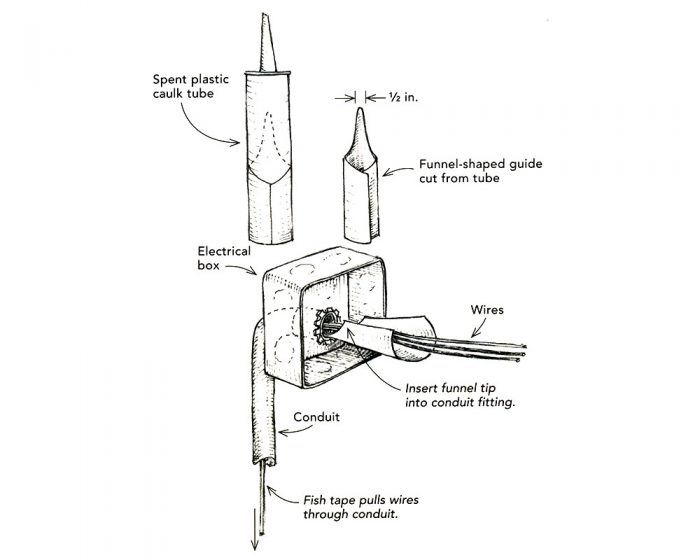

I do a lot of electrical work by myself, and I mostly run conduit. Although pushing fish tape into conduit is easy, pulling the wire back through is not. Regardless of how well I reamed the end of the conduit to remove burrs, I found that my solo wire pulls still nicked the plastic covering on the insulation. Also, the point at which the wires attached to the fish tape, no matter how well taped, always seemed to catch at the fitting inside the box. It was the combination of this fitting, the taut wires, and the 90° bend into the box that caused the problem. The solution turned out to be a discarded caulk tube.

I cut a funnel-shaped wire guide out of a spent plastic caulk tube. Its triangular tip extends into the fitting that secures the conduit to the box, shielding the wires from this sharp corner as they are pulled past it. In just a few minutes, I finished the pull without causing any damage to the wires.

Click here to enlarge the illustration.

—Kenneth B. Best, Elmhurst, IL

Edited and illustrated by Charles Miller

From Fine Homebuilding #178

View Comments

You could also try an insulating bushing on threads of fitting.

I can't imagine what you're doing wrong. I've been doing wiring for over 40 years and have very rarely ever nicked a wire in pull but if what you're doing works for you great.

A true story, which this comment reminded me of: "very rarely ever nicked a wire". I had been working at a gas station in the late 80's. We were full service, so as you can imagine, the worse the weather got, the busier were were. It was common for us gas jockeys to be we wading through an inch (or 6) of slop while checking tires, oil, filling washer fluid, cleaning windshields, putting in Dry Gas, etc.

Then we got a new sign. They dug a big hole between the sidewalk and the curb and poured a huge concrete base, and buried metallic conduit in between the building and the sign, pulled appropriate wiring. All seemed good. Until a bit later, when we had some bad weather, and I kept getting shocked when I touched cars, and worse, saw sparks when I put the fuel nozzle in the car. No one in management believed me until I walked off the job and the owners son experienced the same thing (I still remember him yelling Turn the breakers off!).

Long story short, one of the 220 wires going to the sign had a nick in the insulation. It ended up welding itself to the conduit, buried in the ground. It didn't trip the breaker, but what it did do was to energize the ground. It mostly didn't matter, until everything around the sign and gas pumps was surrounded by a bunch of wet salt-infused slop, and the employees had worked long enough that they were soaked with same slop. My ground differential, once I was conductive enough (from my soaked boots) was enough to shock me.

I'm honestly not sure if today's codes would prevent this (this was the 80's, shortly after leaded gas was outlawed, to give you a time frame.