Q:

When I was in fourth grade, our teachers prepared us for the conversion to the metric system (I still remember the filmstrips we watched). Yet 30 years later, we’re still dealing with feet and inches.

Doug Davis, Terlingua, TX

A:

T.H. Richards, a builder in Mont-Tremblant, Ontario, replies: The standard answer to this question is that the United States, which steadfastly has refused to go metric, uses an enormous amount of 4-ft. by 8-ft. sheet goods and dimensional lumber. Canada manufactures an enormous amount of sheet goods and dimensional lumber. Canadian manufacturers must make their wood products to U.S. standards if they want to sell to the huge U.S. market. Because it’s not cost-effective to produce wood products to two standards, the U.S. standard ends up being the standard for pretty much all building materials manufactured in North America.

Thus goes the materials-based theory of why most Canadian carpenters still work in inches and feet. But there’s another reason for carpenters to stick with the imperial system, one related to the numbers themselves, not to the materials. Although most people can do simple arithmetic in their heads, there’s a problem that crops up when using the decimal-based metric system that happens a lot less often when using the 12-in. foot. It’s called division.

The number 10 can be divided evenly only by 2 and 5. But the number 12 can be divided into whole numbers by 2, 3, 4, and 6. This makes for a lot less skull sweat—and better precision—when doing odd things such as dividing into thirds. One-third of a meter is 33.3333333333333 cm, but one-third of a foot is 4 in., period.

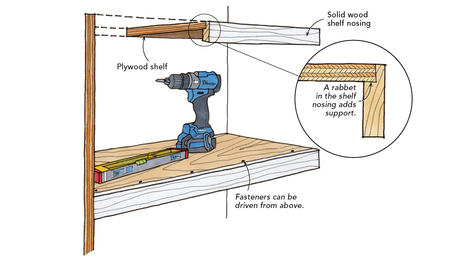

Extending this arithmetic ease to working with U.S. standard sheet-good sizes, one finds that a sheet of 48-in. by 96-in. plywood can be divided evenly three different ways in each direction: 12-in. centers (four or eight spans); 16-in. centers (three or six spans); or 24-in. centers (two or four spans). And that sure makes life easier for a hard-working framer.