Anybody who has ever sweat-soldered copper pipes at close quarters in a wooden house knows the feeling: The torch flame dances around the fitting, glancing off an old floor joist, and some wood smoke fills the air. Will this solder ever melt?

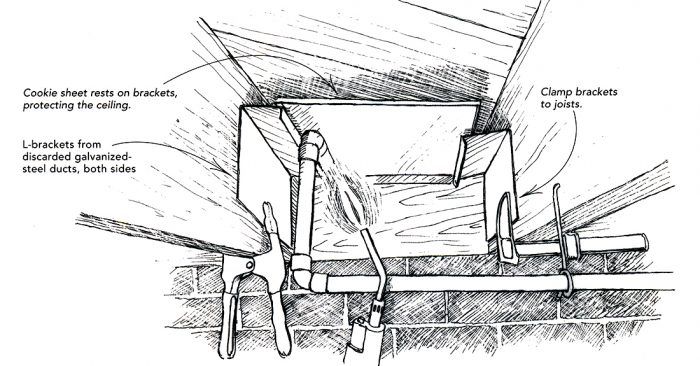

I don’t take any chances when it comes to soldering in a wooden building. I keep an extinguisher on hand, and even more important, I don’t let the flame get anywhere near something flammable. As shown in the drawing , I use a pair of brackets to support an old cookie sheet when I’m working overhead. The cookie sheet shields the ceiling, the brackets protect the joists, and the solder can melt whenever it wants without me worrying about it.

Click here to enlarge illustration.

—John Carroll, Durham, NC

Edited and Illustrated by Charles Miller

From Fine Homebuilding #176

View Comments

Use pex

Nice idea for when customer specification requires use of hard copper for repair. Might try flipping cookie sheet and placing some fireproof insulation between pan and top boards to prevent any heat transfer through metal.

Yeah, although Pex seems to be the standard now days, it's not the professional solution for a house plumbed in copper.

Part of the problem with a lot of the Plumbers of today is they don't have the experience with copper that Plumbers of 20-60 yr.s ago did. Due to Pex piping.

One of the issues I see, is the way you're pointing the torch to solder the joint. That will surely create a problem with fire, and doesn't need to be pointed that direction to get enough heat on the fitting to suck in the solder. Throw away the torch that connects directly to a propane tank, and buy one that has a hose, so it's more maneuverable.

The other is, you're going to too much work trying to protect the surrounding wood. We used (and still use) 1/8" sheet asbestos applied directly against the wood, with sometimes the fitting directly against the asbestos. As long as the torch is pointed in the right direction, and more asbestos shielding the other wood, there has never been a problem. And I can assure you, I've soldered thousands of fittings in over 50 years.

Now I realize asbestos is no longer on the market, but I've had today's Plumbers use a product that's 1/4" thick, that tile setters use, and it seems to work fine. You may also be able to salvage a little asbestos tile that is being replaced.

Leather gloves and eye protection when soldering.

Also

Heat shield made with flame-retardant fibers

Ideal to use when you solder around studs, joists, and walls

Tolerates heat up to 2,500 °F

I'm in Beaumont TX and just recently the city has outlawed all Shark-bite fittings.

Be careful when soldering.