After reading your story on deck fasteners and fastening systems (FHB #178, pp. 78-82), I had to chuckle. When I built my own deck, I wanted to conceal the fasteners for aesthetic reasons as well as for function (not catching something on a protruding fastener) and durability (not creating an entry point for moisture to penetrate the decking).

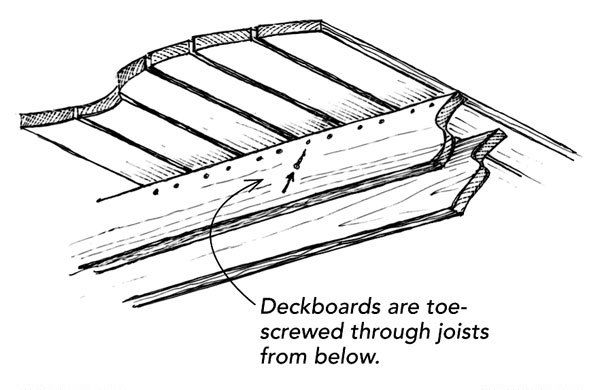

I looked at all the edgemount and bottom-mount systems, and was turned off by their tediousness and taken aback by their price. Instead of investing in one of these proprietary systems, I used GRK R4 Multi Purpose Screws (www.grkfasteners.com) to affix each deck board to its joist from below. As shown in the drawing, I used two 8×2-1/2-in. screws per board at each joist. Working from below, I started the screws about 11/2 in. from the top edge of the joist and angled them at about 30°. That put about 3/4 in. of each screw into the 5/4 deck boards. The sharp “zip-tip” points of the screws eliminated the need to drill pilot holes.

It has been a couple of years since I installed the decking, and it looks great. The decking is solid as a rock without a single squeak, and I saved about $1,500 on mounting gizmos.

—Steve Carle, Edina, MN

Edited and illustrated by Charles Miller

From Fine Homebuilding #182

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Angel Guard Deck Demon

Metal Connector Nailer

Drill Driver/Impact Driver

View Comments

I might try this the next time a client insists on hidden fasteners and the deck is high enough above ground so someone can work from below. I will have lots and lots of one hand clamps with me, even if I’m not working alone.

It would seem that unless the board is clamped tight to every joist, the angled-in-screws aren’t going to pull the board snug against the joist and a gap will result. In case of the first fastening on a board, unless clamped, the board would get displaced.

Aside from getting a high board, gaps are a problem because they are slow to dry out and are a cause of rotting. If dirt gets in the gaps, the problem gets bigger. The only thing worse than narrow gaps are narrow gaps that can’t be readily seen and easily washed out.

I’ve long wondered if the hidden fastener thing isn’t more driven by companies selling these systems than by homeowners insisting on them. Standing on a through-the-board fastened deck, I’ve asked clients if the sight of the screw heads bothers them. Typically they ask what I mean and I have to point out the screw heads that are supposed to be bothering them.

Granted, the little depressions around the screw heads do collect water but unless the screws are way overdriven, this water evaporates pretty fast. As far as preventing rotting, there are a lot of bigger fish to fry.

With some of these hidden fastening systems, it’s just about impossible to take out an individual board. If a deck is very close to ground, that makes access to below (for inspection, cleaning or retrieving a dropped item) essentially not possible.

If a customer insists on hidden fastenings, that’s one thing. On my own property, no way.

I used an under mount system on my cedar deck 18 years ago and it is great. Virtually no splinters and so clean looking. Many people have commented on it.

Late last year I was able to remove all the boards and planed off an eighth of an inch of wood from the top as the bottom was solid. I did have to trim some rot from the edges because I originally did a lousy staining job. I had to purchase some extra lumber to make up for the trimmed rot but it looks great and will look better once completed.

Some of the new screws have enough smooth shank or reverse threading that they will actually pull the two pieces together without over screwing into the first board. This is the same concept as Simpson's new Truss tiedown screws. This method is also good for the latticework on pergolas and other overhead structures.

Powder coated deck brackets. A buck and a half or two a foot for each joist. Ice and water shield over the beams and joists. Stained the boards before installation. Paraffin melted into the end grain with an old iron.

Here is a hot tip. Use CAMO fastners. Best thing I have used for hidden fasnters and I have used every system. Cheaper than a face screw or clip hidden fasnter, looks better, you can replace boards if one goes bad, you dont need to do it from underneath.

A few things to know: You need to use solid boards( no grooves), Edge boards usually require face screws (use small bag of plugs for this). You need a CAMO jig for each guy screwing down deck boards.