5 Roofs That Will Last a Lifetime

These premium products offer time-tested longevity, so your choice depends on price, appearance, and installation requirements.

Synopsis: A house’s roof won’t necessarily last forever, but if it’s installed properly, it can last for a lifetime. Architect Harrison McCampbell offers a guide to five roofing options with long lives: wood, metal, slate, tile, and yes, even asphalt. Each variety of roofing includes noteworthy details and specification information. McCampbell also discusses the ins and outs of roofing warranties.

I’m an architect specializing in moisture problems and solutions. Unfortunately, much of my consulting work involves roofing failures. To me, this is lunacy; we’ve been building roofs that don’t leak for a long time, starting with thatch about 30,000 years ago. Clay-tile roofing appeared around 10,000 B.C., followed by copper (3000 B.C.), slate (2500 B.C.), and wood shakes (12th century A.D.).

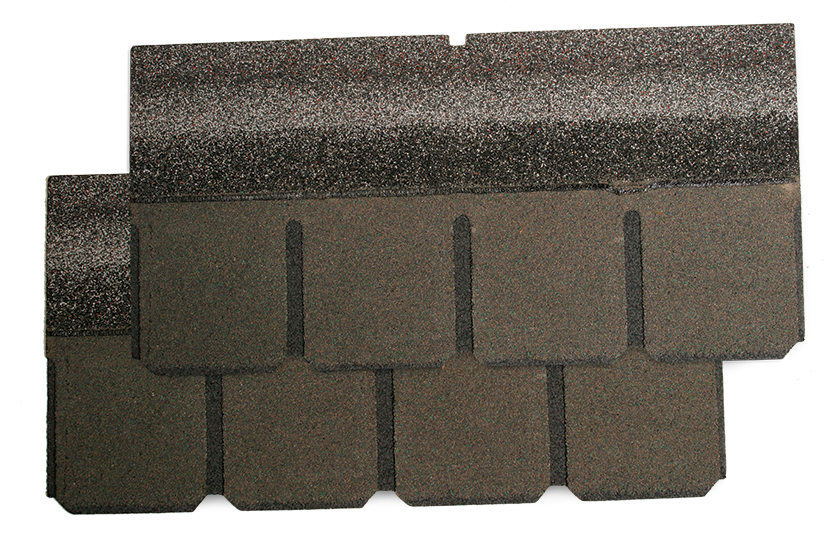

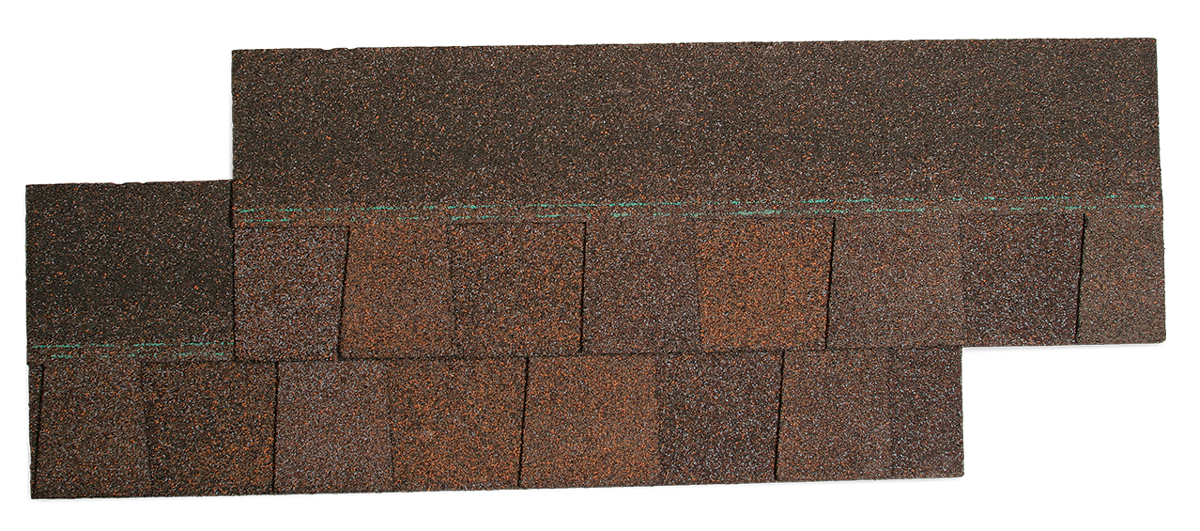

Today, these ancient roofing materials are overshadowed easily by asphalt shingles, which are used on about 60% of houses. But asphalt shingles don’t satisfy the needs of all homeowners. Historic homes often require traditional materials, and extreme climates can narrow roofing choices. And some people just don’t like the look of asphalt.

|

|

|

|

|

Consider regional style and the house’s scale

If price is your only consideration, then 15-year three-tab asphalt shingles beat any other material hands down. If durability is most important, then a permanent solution such as standing-seam copper might bubble to the top of your list. But these things aren’t the only considerations.

Think about the style and structural integrity of your house. Clay tiles are common along the southern tier of the United States, but less common in New England. Also, the scale of the roofing material ought to match the scale of the house. Small roofs look goofy with large concrete tiles. The existing roof structure might dictate what you can and cannot do easily. Some old houses have 2×4 roof framing on 2-ft. centers. This framing simply isn’t strong enough to support a heavy roof. But a lighter material, such as metal, often can be installed directly over existing shingles.

Climate matters, too. Traditional choices typically evolve in an area because they work well. Tile roofs do well in hurricane-prone areas (with proper detailing). A standing seam terne-coated stainless-steel roof resists the corrosive salt air of a coastal climate. A lifetime roof might not be worth the investment if you’re planning to move within a few years. And depending on your roofing choice, you could get a break (or take a hit) on your homeowner’s insurance. Finally, think about repairing the roof. If a large branch falls on your roof after a storm, will you need a total reroof? Can you actually walk on it to make the repair? Clay tile and slate are brittle, so repair can be a challenge; metal roofs can be slippery to walk on.

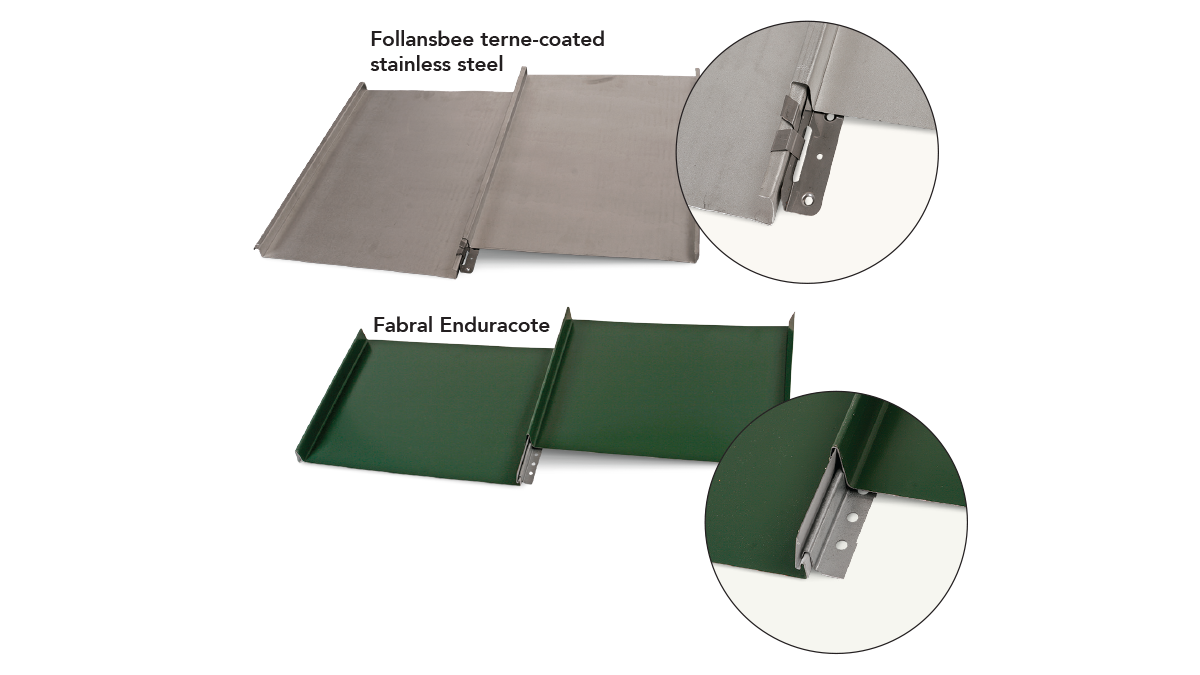

Standing seam is the best metal roof Specs Material cost per square: $260 to $900 Installed cost per square: $400 to $1400 Materials-to-labor ratio: 65% materials/35% labor Weight: 0.5 lb. to 1.75 lb. per sq. ft.

“Standing-seam copper roofing is my favorite residential-roof system, for its durability and good looks” says Rick Ragan, owner of Southern Roofing Inc. in Nashville, Tenn. “Because standing-seam panels have concealed fasteners, the roof should never need to be replaced.” Metal roof panels also are manufactured with contours or textures to imitate the look of roof tiles and wood shakes, but these lightweight preformed panels dent under foot traffic or storm-related damage. “Those panels may be OK in places without many trees or high winds, but I’ve pulled enough trees off of roofs after hurricanes to stay away from them,” says builder Michael Chandler in Chapel Hill, N.C. As in the photo at left, a standing-seam roof can be fabricated on site with shears, brakes, and other tools that turn flat sheet metal (copper, in this case) into seamed panels. More often, factory-made panels are used. Installation details for site-made and factory-made panels are similar. Panels join along vertical seams that either snap or are crimped together. Panels are held in place with clips that are nailed to roof sheathing. Installation details must account for expansion and contraction to avoid buckling. |

Installation matters because warranties are relative

Proper installation is critical with any type of roofing material. Improperly installed roofs can leak. Sloppy installation details can void the warranty. Installation details are specified according to how a material is developed and tested in the manufacturer’s lab, and the warranty is written according to this research to provide a consistent product that the manufacturer can stand behind.

But realize how warranties originate: as a sales tool. Asphalt shingles, for example, used to be differentiated by their weight: 200 lb. per square as opposed to 250 lb. per square (a square equals 100 sq. ft.). This means little to a consumer, so marketers translated these numbers into serviceable life: 15-year, 30-year, and—more recently—even lifetime warranties.

Some features in a warranty, however, are aimed more at the sales aspect and less at the “stand behind their product” part. Prorated warranties (those that pay less as time goes on) are a good example. This sliding-scale compensation limits losses while allowing the manufacturer to put a big number on the time scale. Another warranty hook is transferability. Some manufacturers take advantage of the average homeowners’ 10-year stay in a house and void a warranty when the original buyer transfers ownership.

“I don’t have any faith in our ability ever to collect on an asphalt-shingle warranty,” says roofing contractor Stephen Hazlett of Akron, Ohio. “On almost every roof, I have to deviate from the recommended procedures.” Such deviations are often from the specified nailing pattern. A shingle could butt against a chimney or a waste-stack flashing, requiring a nail a couple of inches away from the specified location. If the placement doesn’t match the shingle company’s specs, the manufacturer might not honor the warranty. While some manufacturers offer more liberal nail-placement specs, most are strict about nail location.

While Hazlett hasn’t had a warranty problem, he thinks a warranty’s real value is relative: A 50-year shingle might or might not last 50 years, but it will outlast a 15-year shingle substantially. Bottom line for warranty shoppers: Look for transferable warranties and, if possible, warranties that aren’t prorated.

For asphalt roofs, qualified installation contractors are ubiquitous, but for more exotic materials, qualified installers can be scarce. Look to trade organizations for local contacts.

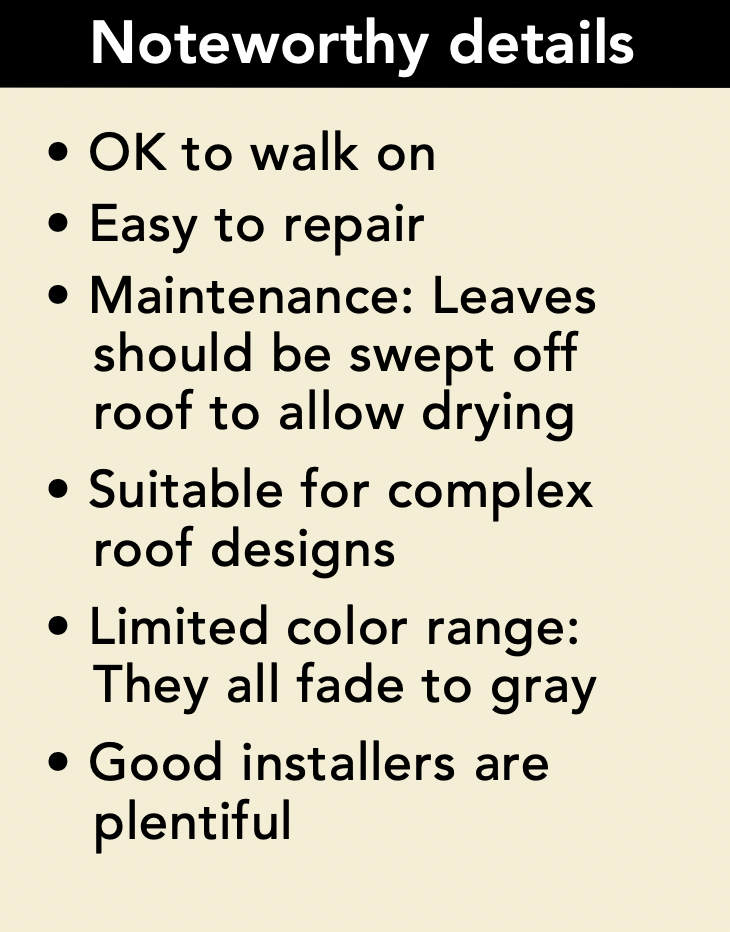

Wood roofing is simple to install on complex roofs

Specs Material cost per square: $200 to $600 Installed cost per square: $700 to $1000 Materials-to-labor ratio: 60% materials/40% labor Weight: 0.35 lb. to 1.5 lb. per sq. ft.  In spite of the red, white, and yellow in their names, all shakes and shingles weather to gray after a year or so. While it’s possible to use kiln-dried (KD) prestained shingles on a roof, it’s difficult to maintain the color, especially if you want it to match a house’s sidewalls. Prestained shingles also require extra installation attention. “Be very careful of your spacing,” advises Lloyd Clefstad, president of www.woodroof.com. “When wet, KD shingles can expand 4%, which, without the proper spacing, will cause buckling, breaking, and eventually roof leaks.” Class A, B, and C fire ratings are available based on factory-applied treatments, but some cities in California don’t allow any type of wood roofing regardless of its fire rating. Shakes and shingles are easy to cut and install, and wood roofs can last a long time. Red cedar can last up to 30 years, Alaskan yellow even longer. Pressure-treated pine is warranted for 50 years, and white oak often lasts for 75 years. All wood roofs last longer if they can dry evenly. If the back can’t dry as quickly as the front, shingles can cup, crack, and work loose. To promote even drying, you can install the roofing on skip sheathing, weaving felt paper between courses, or install shingles over a drainage mat such as Cedarbreather (www.cedarbreather.com). |

What’s on my house?

I always have liked California mission- or Mediterranean-style homes. The mission “pan and barrel” tile, set in mortar, is my favorite residential roof. Copper is my metal roof of choice for its looks and durability. Did I use either when I reroofed my own house last year? No. I used a laminated 30-year asphalt shingle because mission tiles would have looked silly on my brick ranch and asphalt shingles were about one-third the price of copper.

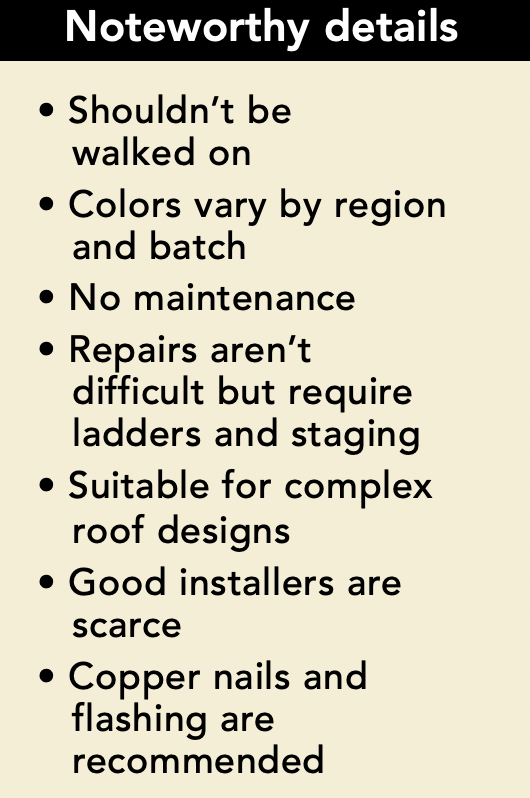

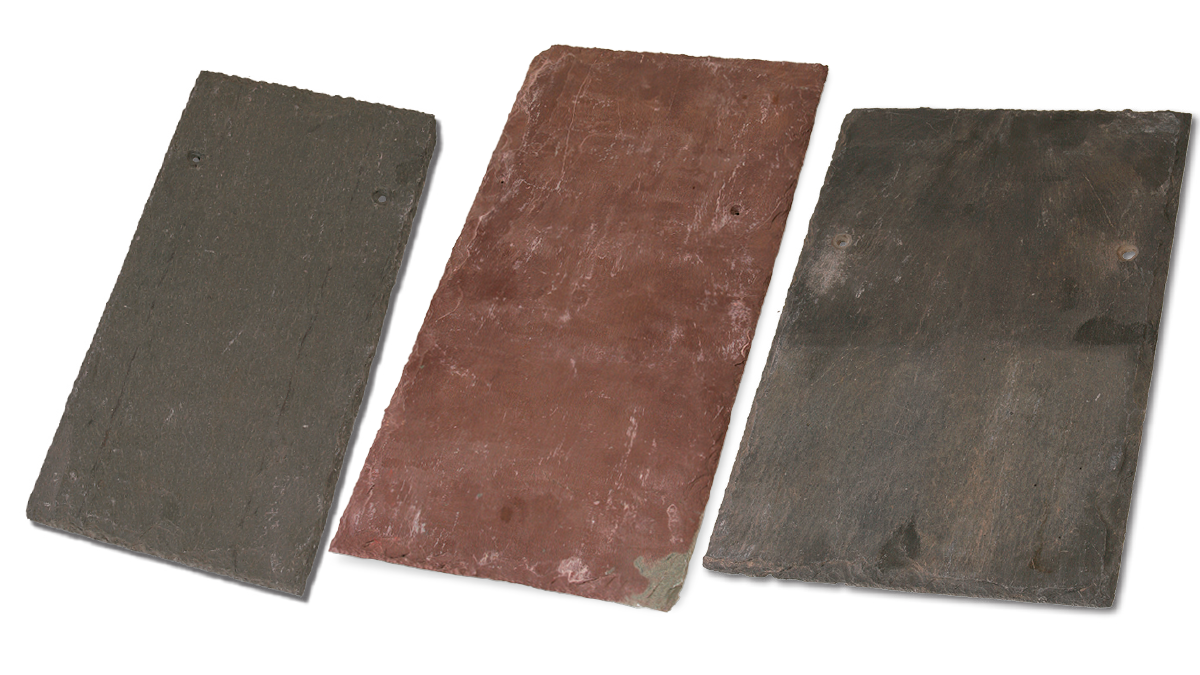

Slate is a traditional choice that lasts hundreds of years

Specs Material cost per square: $350 to $800 Installed cost per square: $1000 to $1340 Materials-to-labor ratio: 60% materials/40% labor Weight: 6 lb. to 11 lb. per sq. ft.  Slate roofing went through a bottleneck in the 1950s with the increased use of asphalt roofing, and many old-timers who knew trade secrets are gone. That’s why it can be challenging today to find truly skilled installers who know the correct details for starter courses, valleys, ridges, and even the staging that allows an installation to be completed without anyone walking on the slate. The advent of power tools hasn’t had much effect on how slate roofs are installed. It’s still a process done largely by hand. But the reward for this labor-intensive process is a roof with exceptional character and longevity. |

Roof tiles are made with clay or concrete

Concrete Specs Material cost per square: $280 to $320 Installed cost per square: $700 to $800 Materials-to-labor ratio: 40% materials/60% labor Weight: 8 lb. to 18 lb. per sq. ft.

Clay SpecsMaterial cost per square: $600 to $750 Installed cost per square: $1200 to $1500 Materials-to-labor ratio: 50% materials/50% labor Weight: 11 lb. to 14 lb. per sq. ft.

Both clay and concrete are fireproof, with excellent wind resistance when installed properly. But installation can be tricky: You need to install wood battens on the roof and along the hips and ridges as well, tiles need to be cut with a diamond-blade saw, and underlayment must be exceptional, often #90 rolled roofing. Because roof tiles last a long time, you need to use durable fasteners and flashings. Tests by the Tile Roofing Institute have shown that wind clips and specially placed adhesives let tile roofs sustain 125-mph winds. The biggest disadvantage with concrete and clay is weight, but this problem is solved easily with beefed-up framing. |

Harrison McCampbell, AIA, specializes in moisture issues within the building envelope. He lives and works in Brentwood, Tenn. Photos by Krysta S. Doerfler, except where noted.

From Fine Homebuilding #185

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

All New Bathroom Ideas that Work

Not So Big House

Fall Protection

View Comments

Were I to have a choice , I'd go with slate ,however here on the wet coast of BC , I've onle installed two slate roofs in 35 years .. A shame I think , worked on lead roofs that are 100plus years old and only worked on them to replace the lead flashings.