Q:

It seems to me that it would be a lot easier to install rigid-foam insulation inside the framing rather than outside because of all the details such as cornice returns and exterior window trim. I’d like to use 1-in. foil-faced foam, which will be a reflective barrier, then apply 3/4-in. strapping to screw the wallboard to. What do you think?

Fitz Gensheimer, Millbridge, ME

A:

Bruce Harley, author of Build Like a Pro: Insulate and Weatherize, replies: If you build a house this way, you probably will end up with a fine wall system, but the reflective barrier and airspace do almost nothing for you once you have a decent amount of conventional insulation. Radiant-heat transfer depends on a big temperature difference, and unfortunately, there will be almost no temperature difference between the inside surface of the foil-faced insulation and the back side of the drywall in your proposed assembly. No temperature difference, no radiant-heat transfer, no benefit.

I prefer walls with continuous rigid foam on the exterior for a couple of reasons. First, it’s easier to make continuous. Although exterior details around porch roofs, entryways, and garages can be tricky, interior foam has to be worked around every partition wall and floor joist that intersects the exterior wall; the interruptions diminish its value.

Second, although either approach reduces the risk of moisture damage from interior water vapor in all seasons and climates, only exterior foam also can enhance the rain-shedding and drying potential of the wall. Interior foam keeps the framing cooler for most of the year (particularly in cold, wet climates), which reduces the drying potential and requires perfect flashing and siding details. Exterior foam keeps the framing warm and dry, which makes the wall more tolerant to occasional leaks because the wall can dry.

My final suggestion for your walls: Instead of a 2×6 wall with 1-in. foam, build a 2×4 wall with 2-in. exterior foam and unfaced R-13 batts. You’ll end up with a slightly higher net R-value; you’ll buy less wood; and you will better control the condensing temperature of the exterior sheathing, which is important in a cold climate.

You don’t need an interior vapor retarder, and depending on the siding, trim, and furring strips, you might be able to use standard window and door extension jambs designed for 2×6 walls. (If not, you might be able to make it work with 1.5-in. rigid foam.)

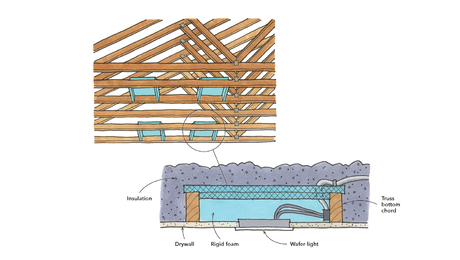

By the way, consider using sprayed-foam insulation for the insulated rafter areas. It is more moisture-tolerant than fiber insulation, and it does not require venting (according to section 806.4 of the 2006 IRC), which can be difficult to do with some roof shapes.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Respirator Mask

Loctite Foamboard Adhesive

Anchor Bolt Marker

View Comments

I'm interested in insulating an existing house that currently has no insulation at all. It's an older home and over the years it has settled and the wall lathe/plaster has cracks in it. I wonder if it would be reasonable to insulate the inside of the exterior walls and ceilings with polyiso and cover the insulation with fir strips and new drywall. I should be able to seal the polyiso well and minimize air infiltration, etc. What I'm not sure about is the suitability of using polyiso in an interior application in terms of trapping moisture inside the house, etc. The ceilings are high, so reducing room height by 3-4 inches would not be a problem. Adding thickness to the outer walls would create some additional work, but likely less than removing the lathe and plaster.

This has been up for awhile, everybodies got a comment regarding foam this and foam that? Why not think outside the box?

Let’s design your homes with outboard insulation as part of the design in the first place? I like Bruce’s comment about 2x4 walls, but not the part of foam! Why not just add a bunch of oil cans around your house…that’s pretty good insulating, right? I have a house right now with 2x4 walls that we’ve gutted, using Havelock wool, and Steico 2 3/8 as outboard, maybe extending on the inside 2x2s to the studs to make them 2x6? Just maybe getting around R32 with a rain screen added.