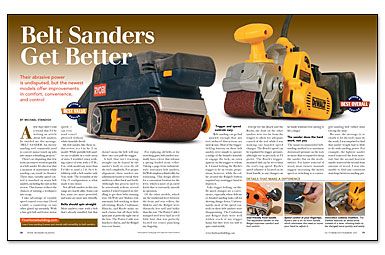

Belt Sanders Get Better

The newest models offer improvements in comfort, convenience, and control.

Synopsis: When it comes to removing wood quickly, few tools can match the power of a belt sander. Finish carpenter Michael Standish takes a look at the current crop of belt sanders in this tool review. Michael assesses the basic makeup of a 3-in. by 21-in. belt sander, then compares eight models now available. This article includes a chart for quick comparisons in a variety of categories, including price, weight, noise level, and accessories, along with Michael’s testing results. The article also includes a sidebar about the potentially explosive hazard of sanding different metals with the same sanding belt.

A few days after I told a friend that I’d be writing an article about belt sanders, he emailed me this message: “BELT SANDER: An electric sanding tool commonly used to convert minor touch-up jobs into major refinishing projects.”

There’s no disputing that few tools can remove wood as quickly as a belt sander. It’s also true that a moment of inattention while sanding can result in disaster. These days, variable speed control is standard on many belt sanders, including the ones in this review. This feature reduces the chances of turning a workpiece into scrap.

I take advantage of variable speed control every time I level a table, a countertop, or any other glued-up assembly. With a fine-grit belt and lower motor speed, I can even sand veneer plywood without white-knuckle dread.

My belt sander, like those in this review, is a 3-in. by 21-in. model. While portable belt sanders are available in a wide array of sizes, I wouldn’t enjoy scribing a piece of trim with a 15-lb., 4-in.-wide model any more than I’d like to sand a 2-ft. by 6-ft. tabletop with a belt sander only 3⁄8 in. wide. The versatility of the 3-by-21 configuration is what made it my choice.

Not all belt sanders in this size range are exactly alike. Some cost less, some are more powerful, and some are more user-friendly.

Belts should spin straight

Most sanders come with a belt that’s already installed, but that doesn’t mean the belt will stay there once you pull the trigger.

A belt that isn’t tracking straight can be frayed by the sander’s body or even fly off the tool completely. For proper alignment, these sanders use adjustment knobs to tweak their undriven rollers back and forth. Although this process used to be notoriously tedious, several sanders I tested required no fiddling to get their belts running true. DeWalt and Makita tout automatic belt tracking in their advertising. Bosch, Craftsman, Hitachi, and Ryobi make no such claims, but all their belts spun just as perfectly right out of the box. The Porter-Cable was finicky to dial in, and the Ridgid was even fussier.

For replacing old belts or for switching grits, belt sanders normally have a lever that releases a spring-loaded front roller. Taking a page from industrial-style stationary belt sanders, DeWalt employs a third roller for tensioning. This design allows for a convenient location for the lever, which is more of an eared knob that is extremely smooth in operation.

Of the other models, which use the traditional lever between the front and rear rollers, the Makita and the Ridgid were distinctly less stiff and balky than the rest. The Porter-Cable’s stamped steel lever had an evil little burr that was perfectly located for center-punching my fingertip.

Magazine Extra: Learn how sanding frames and sander stands add versatility to belt sanders.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

DEWALT Impact Driver (DCF885)

DEWALT 2 1⁄4-hp Router Combo Kit (DW618PK)

Hitachi Pin Nailer (NP35A)