A Different Way to Use a Basin Wrench

Sometimes you have to get creative when it comes to installing compression-fitting angle stops.

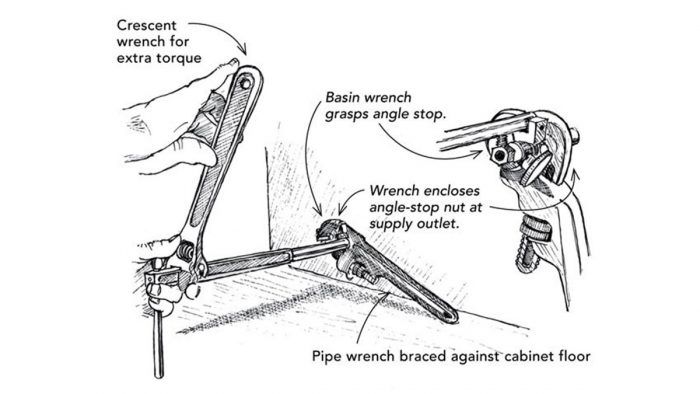

Sometimes there just isn’t enough room in a base cabinet, or some other confined workspace, to get the leverage required to install compression-fitting angle stops. In this situation, I turn the angle stop instead of the nut that secures it to the supply line. As shown in the drawing, I enclose the angle stop’s nut with a pipe wrench braced against the cabinet floor. The basin wrench grabs the body of the angle stop, which is then threaded into the nut held by the pipe wrench. If I need a little extra torque, I add a crescent wrench to the team.

— Henry Wong; Thousand Oaks, CA

From Fine Homebuilding #194

RELATED STORIES

Got a Tip?

Do you have any great tips like this one on how to make installing compression-fitting angle stops easier? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at tips@finehomebuilding.com, or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

View Comments

been there. done that. the pinkie on the wrench is a nice touch.

..and this is Fine Homebuilding? Just pass the problem on to the next person... I dare say one would barely have room to turn the handle on that valve.. ..and who uses those crummy valves that seize-up and leak. Little shut-off ball valves are so inexpensive anymore. ...and toothed pipe and basin wrenches on soft brass? No wonder so many people think poorly of contractors. Pull the cabinet, add a short stub of tubing and do it right.--That's Fine Homebuilding.

Ball valves may have compression fittings also, so the technique would also apply there. This technique can be used if one is removing instead of installing.

Good tip.