What's the Difference: Galvanized nails

Which type of zinc-coated nail is the best at preventing corrosion?

To prevent rust, nail manufacturers apply zinc to steel nails using three fairly distinct processes: hot-dipped galvanization, hot galvanization, and electrogalvanization. Each treatment offers a different level of corrosion protection with price tags to match. No nail on the market—except, ironically, those coated with zinc—can ruin stainless-steel hardware. Never use galvanized fasteners to attach stainless hardware, or vice versa.

Hot-dipped nails

During this process, nails are immersed in kettles of molten zinc at 860ºF. The zinc and steel form an alloy coating extremely resistant to chipping during handling and installation. The coating is about 85 microns thick, of which some 40 microns is chip-resistant zinc-iron alloy. These nails may be quenched, too, yielding a somewhat shinier product that some builders prefer. Hot-dipped nails are typically the most-expensive type of galvanized nail.

Uses: Hot-dipped nails are rated for use wherever corrosion is a concern, except in coastal environments where stainless-steel fasteners reign supreme.

Hot-galvanized nails

In this process, nails and powdered or chipped zinc are placed in a rotating drum and tumbled together at 860ºF until a zinc-iron alloy forms on the nail as it does in hot-dipped galvanization. The alloy forms 30 microns of the 45-micron-thick coating, which, while not as thick as the coating on hot-dipped nails, is equally hard. There is a caveat, however: Many major manufacturers use this process, but if quality control is less than stringent, coating thickness can vary, compromising corrosion resistance. Hot-galvanized nails are only moderately expensive compared to hot-dipped nails.

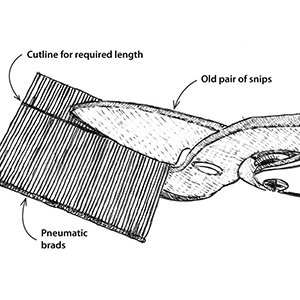

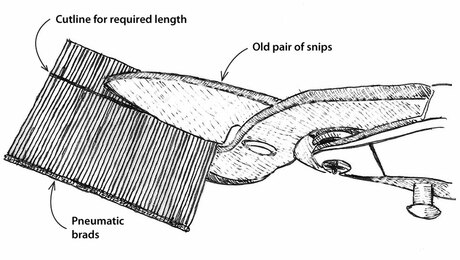

Uses: These nails are rated for weather exposure and pressuretreated lumber, but don’t use them in severe conditions where they’ll be immersed in water or buried. You’ll be hard-pressed to find a pneumatic version of these nails.

Electrogalvanized

Electrogalvanization is really electroplating. A nail placed in a solution of zinc salt is electrically charged, which causes the zinc molecules to bond to the nail. Those silky-smooth, shiny silver nails you see are coated with soft, pure zinc as a result of electrogalvanization. These nails are the least-expensive type of galvanized nail.

Uses: Electrogalvanized nails don’t have enough zinc on them to withstand the effects of treated lumber or harsh outdoor conditions. They are rated for use as roofing nails when protected by shingle tabs.