What's the Difference: Metal countertops

A materials survey of countertops covering stainless steel, zinc, pewter, copper, and bronze

So, you can easily discern soapstone from granite, granite from marble, and marble from any other stone-countertop material. But can you identify stainless steel, zinc, or pewter? How about copper or bronze?

The popularity of metal-countertop materials has grown considerably over the years. All of them offer homeowner-friendly benefits. They’re all easy to keep clean and are relatively resilient when treated with care. However, none are inexpensive, and metal prices fluctuate so often that speaking in generalities is more accurate than giving definitive numbers. Here’s what distinguishes each material.

Stainless steel

An alloy of carbon steel, nickel, and chromium, stainless steel doesn’t oxidize or develop a patina like other metals, so it has a consistent look throughout its service time. Although stainless doesn’t have the antimicrobial benefits of some other metals, it is less porous, which means it’s easy to keep clean. Stainless steel is classified into “series” based on the percentage of each component element, and it is further classified into “grades” based on its crystalline structure. Countertops most often are made of grade-304 stainless, the hardest of the materials discussed here and the most scratch resistant.

Finishes: Stainless-steel finishes are numbered from 0 to 8 based on their polish; the higher the number, the shinier the surface. However, a brushed finish is most popular for countertops because it shows less wear and fewer fingerprints than a mirror finish. Brushed finishes can be maintained with a product called Beekeeper’s Friend.

Cost ranking: Lowest

Zinc

Zinc is a discrete element, whereas stainless steel, pewter, and bronze are alloys. An ordinary gray color, zinc is known (if at all) as a countertop material for oyster and seafood bars in Europe. Seams are welded and should be ground flush, but they are often visible due to color variations among zinc sheets. A good designer or fabricator can suggest a design compatible with the maximum sheet size, which is usually around 120 in. by 39 in. Zinc is not as hard as other metals, so it should be cleaned with a nonabrasive cleanser, and trivets should be used whenever possible to prevent damage.

Finishes: Zinc counters can be polished to a mirror sheen, but that’s like polishing your work boots. The natural finish will develop a patina, or oxidation on the metal’s surface. Applying beeswax can help to keep the countertop looking new.

Cost ranking: Low

Pewter

Pewter, an alloy that is mostly tin, resembles zinc in that it is naturally gray in appearance. When pewter develops a patina, it becomes a deep gray. Like zinc, pewter counters can create a distinctly European style as their use is more prevalent there. Pewter is the softest of these metals and melts so easily that it must be soldered, not welded. It is not as resilient as other metal countertops, but its softness is suited to intricately worked edge treatments. Like other soft metals, pewter should be treated with extreme care. Abrasive cleaners will scratch it, and a hardworking kitchen will take its toll.

Finishes: The results of aging are the same as zinc. Pewter countertops should also be maintained with beeswax.

Cost ranking: Highest

Copper

According to the U.S. Geological Survey, copper ranks as the third most widely consumed metal on earth and one of the first metals used by man. When used in the kitchen, it can provide both an industrial and an old-world look. Like other metals, copper develops a patina over time, and its bright luster dulls as it ages. More so than other metals, copper has an inherent antimicrobial quality, which makes it a hygienic countertop option. Copper is relatively soft and malleable, so it should be treated with care to prevent damage.

Finishes: Copper can be polished to a high shine, left untreated so that it develops a patina, or chemically “aged” and sealed. Its finish can be maintained with copper cleaner and with waxes such as Trewax.

Cost ranking: Moderate

Bronze

Bronze is a metal alloy primarily composed of copper and tin, but it can contain other elements. It develops a patina over time, turning a dark, golden-brown color. Only a stainless-steel countertop is harder than bronze. However, bronze can still be scratched; as with all other metal countertops, cutting boards should be used. Bronze can be cleaned with a nonabrasive cleanser.

Finishes: The options are the same as zinc, pewter, and copper. Bronze countertops are often appealing to those who like the look of copper but find its hue too jarring. The finish can be maintained with the same products used for copper.

Cost ranking: High

Why not aluminum?

Inexpensive and readily available, aluminum seems like a great countertop option. So why, then, does aluminum seem to be the least popular metal among manufacturers and fabricators?

Aluminum is much softer than stainless steel but is still relatively resilient. The material has a few major drawbacks, though. Aluminum that is not treated with a protective finish, like a powder or clear coating, can stain and oxidize when it comes in contact with water and other substances found in kitchens. Unlike other metals, oxidized aluminum has a white, crusty appearance. It doesn’t look patinated or well aged; it just looks unattractive.

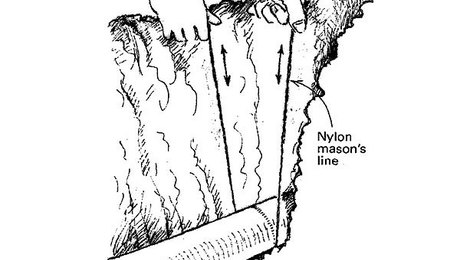

Aluminum can be bent easily, but fabricating the metal into a countertop can be very difficult. Welding aluminum is extremely hard, especially when working with the thin 16-ga. metal that most countertops are made of. Aluminum’s susceptibility to warping under extreme heat is heightened by the process.

Photos by: Dan Thornton, except where noted