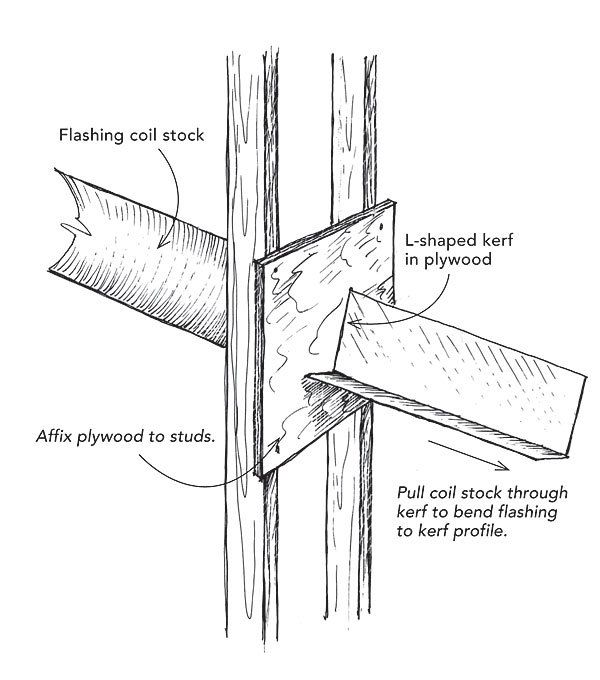

Here’s a simple method for bending a long piece of flashing on a job site. It works with thin-gauge galvanized steel and copper, but for best results, I recommend aluminum coil stock. As shown in the drawing, simply cut a sawkerf in a scrap of plywood the exact size and shape of the desired flashing profile. Take care not to make the sum of intersecting sawkerfs any greater than the width of the flashing.

Nail the plywood to a couple of wall studs, and start feeding the flashing through the kerf. As you push, have a helper pull the flashing from the other side. Like magic, what comes out is a beautiful piece of custom-bent flashing right off the coil as long as you want. Need 100 ft.? No problem. You just need a few more helpers to keep it from deforming. Practice makes perfect with this technique. You can even make multiple bends with it.

David Kalin , Kaneohe, HI