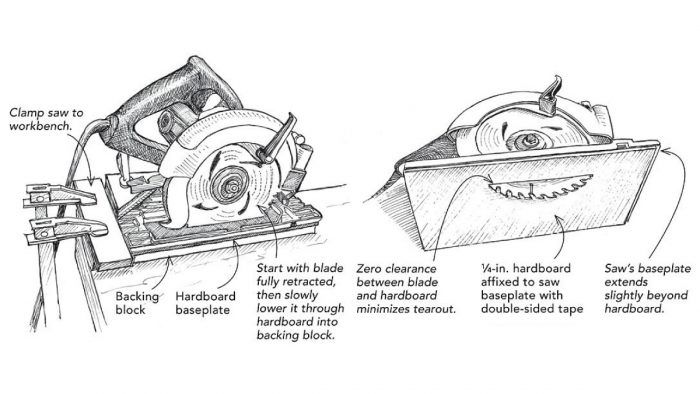

As a one-man trim-carpentry crew, I often use a circular saw to cut full sheets of cabinet-grade plywood to manageable sizes before making final cuts with my tablesaw. To minimize tearout, I’ve devised the zero-clearance circular-saw base.

I start by measuring the saw’s baseplate. Then I cut a scrap piece of 1/4-in. hardboard slightly shorter in length and width so that it doesn’t protrude beyond the saw’s baseplate edges (they need to slide against my straightedge guide during cuts).

Next, I retract the blade so that it no longer extends through the saw’s base, and I adhere the hardboard to the saw’s baseplate with double-sided tape. With the blade in this fully retracted position, I clamp the saw to my workbench with a sacrificial block thicker than the stock I plan to cut sandwiched between the saw and the bench. I turn on the saw and slowly lower the blade through the hardboard and into the block until I’ve reached the necessary depth. The saw is now ready to go.

When I’m finished making my cuts, I pop off the zero-clearance plate by inserting a flat-bladed screwdriver or putty knife between the two baseplates and twisting.

Click here to enlarge the illustration.

Magazine extra: Watch a video where Chuck Miller demonstrates this tip.

—Tom Walter, Alexandria, VA

Edited and Illustrated by Charles Miller

From Fine Homebuilding #202