The 2009 International Residential Code (IRC) has a number of big changes when it comes to framing decks. If your state, county or town will be adopting the ’09 IRC you’d better take a look at a copy of the code before you get a code violation.

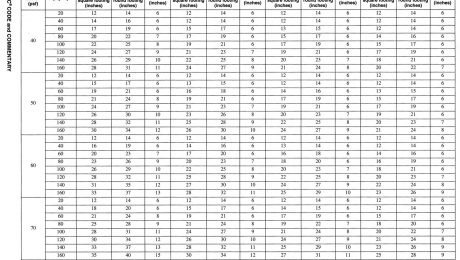

The changes are all related to how you connect the ledger to the building. For one, there’s now a prescriptive chart for fastener patterns, no more ‘rule of thumb’ bolt or lag screw frequency. You just match the depth of your deck to your fastener of choice (1/2 inch lag screw, 1/2 inch thru-bolt or 1/2 inch thru-bolt with stacked washer space) and you’re good to go. But you are going to need a structural engineer if you want to bolt your deck ledger to anything but a 2x rim joist or a 1 inch thick Douglas Fir LVL rim. This means you have to know how the floor is framed when adding a deck to an existing building. Plus if the rim joist is concealed on the inside, you have to provide some sort of visual access for inspections – get out the hole saw….

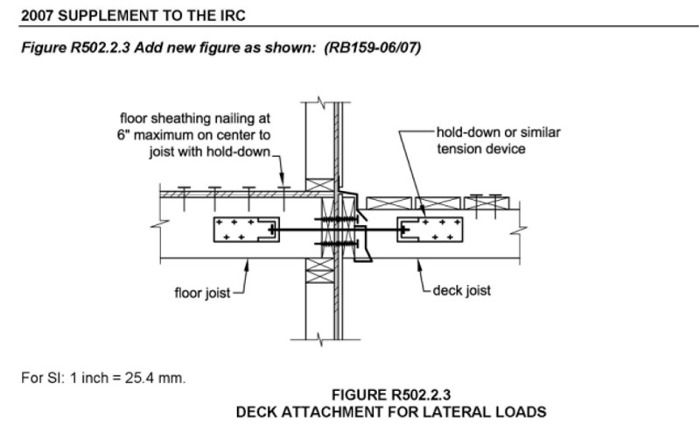

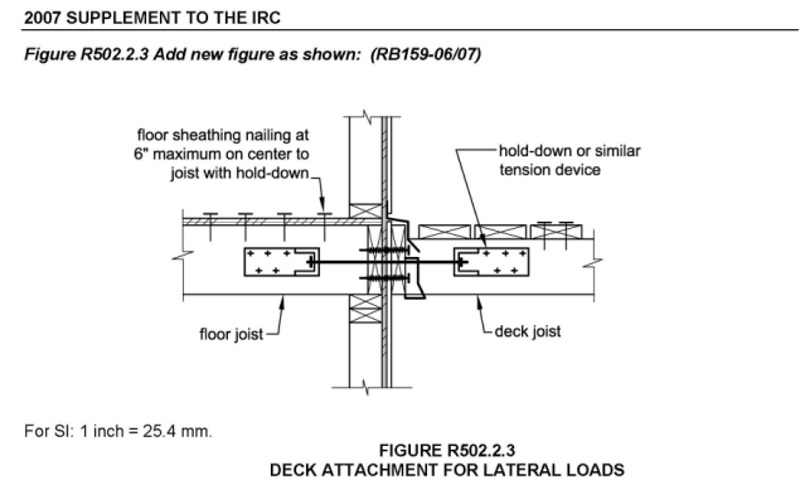

And if you never noticed the one code provision that’s been included in the IRC for years in section R502.2.2 that says: “Where supported by attachment to an exterior wall, decks shall be positively anchored to the primary structure and designed for both vertical and LATERAL loads as applicable” then you will when you look at the new section R502.2.2.3 Deck lateral load connection. There’s a new prescriptive lateral load connection option you can use to keep the deck from pulling away from the building. Even though you are not required to use the detail, it will most likely trigger the notion in your local building official’s head that “Hey, I should enforce something.” And unless you have an engineered alternative solution, your local inspector may require that you use the connection as detailed.

Take a second look at the drawing above – the detail uses a long threaded rod that connects the floor joist of the house to the floor joist of the deck. On the bright side, you only have to install a couple of these on each deck (yeah, even if it’s just a 4 ft wide landing deck). The trick of course will be finding the brackets; they aren’t commonly stocked yet. Right now there are only 2 available – the Simpson Strongtie DTT2Z and USP’s DTB-TZ – that meet the 1500 lb. load requirement.

If you don’t have your copy of the 2009 IRC you can get most of the information from the 2007 supplement to the 2006 IRC online at the ICC website. Check out pages 34 – 36 for the deck sections.

There are other provisions in the new deck section of the code that eliminate mounting a ledger to a cantilevered floor and prohibit mounting girders to a ledgers, and a few other things. So before you get a violation notice and have a bear of a time revamping your deck frame to meet the new code, keep apprised of your local adoption schedule for the 2009 IRC and check it out.

Editor’s note: If you are planning to take on a deck project this summer, in addition to the 2009 IRC, you’ll want to consult our new Deck Planning Center. The IRC covers the code, our planning center covers everything else.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

A Field Guide to American Houses

Graphic Guide to Frame Construction

Get Your House Right: Architectural Elements to Use & Avoid

View Comments

Awesome post, Mike. Thanks so much for sharing this important info with your peers.

Hey Mike,

Thanks for the info. Question though...you say that, so far, the only bracket that will satisfy the code is the Simpson DTT2Z. Doesn't something like the Maine Deck Bracket (www.deckbracket.com) essentially do the same thing?

I built my deck a few years ago and used a procuct called deck-lok (www.deck-loc.com) to attach the ledger to the inside floor joists. Similar to the question JFink asks, doesn't this do the same thing? Do you know if the Deck-Lok product meets the new code. Thanks for the useful article.

As a state certified residential contractor from Florida wood construction connectors, anchoring and fastening systems play an important role in designing and building structures that are stronger and safer.

Down here only state certified contractors can pull permits and all structural work needs licensed engineering stamp approved plans before any work can commence or you risk penalties, fines and you can kiss your license good- bye.

Build safe

As far as the maine deck bracket goes, it appears to simply bolt to the rim joist (which would have to be the solid 2x or 1x LVL mentioned). It would apparently satisfy the bolting requirement for shear, but doesn't have the lateral resistance of the hold down, unless there's some method for tying it back to a joist. I haven't actually used the deck bracket, so I could be wrong.

The hold down's threaded rod is grabbing the joist like a drag strut and using the floor diaphragm to spread that 1500# of axial load out, hence the showing of max 6" nail spacing through the floor sheathing into the joist.

Also, I imagine if the floor joists run paralell to the ledger you'd need to install solid blocking through a few bays, again to drag that 1500# axial load through enough floor diaphragm nailing.

(I think.)

k

Justin, Ed,

Cut to the chase - DeckLok brackets will not work; their load rating is too low and can't be used to comply with the prescriptive code requirement of 1500 lbs lateral load resistance. Maine Deck Brackets (MDB) don't work because they only connect ledger to band joist. The code requires the deck joists to be connected to the house joists for lateral resistance. This is to avoid the problem where decks fall due to the house band joist pulling out of the wall (and going down with the deck) OR the deck joists pulling away from the ledger board (ledger left on wall, deck on ground). MDB's can be used but we still have to add the DTT2Z bracket system (or other locally approved method).

Background - I called Michael Morse - owner of MT DeckLoK and maker of the DeckLok bracket in March when I reviewed the freshly printed 2009 IRC deck code provisions. Although he was the person who initially proposed more stringent deck codes to the ICC back 10 years ago or so and started ICC looking into the issue, he did not keep abreast of the most recent provisions and was not aware of the prescriptive connection detailed in the code (until I alerted him).

DeckLok brackets are rated for 900 lb load and the IRC prescriptive ledger connection bracket system requires 1500 lbs (at each bracket). So DeckLok brackets will not meet the code requirement. That noted, Michael directed me to one of his lateral load resisting deck to house connection at http://mtdecklok.com/ . That detail uses 4 DeckLok brackets to mount offset deck and floor joists using the house band joist and deck ledger for intermediary load transfer. Michael said that since his brackets are rated at 900 lbs and the detail pairs them (2 inboard and 2 outboard) that you could use his brackets to comply with the intent of the code provision.

However, since he does not have an ICC-ES report showing the compliance then it will be up to any user of the DeckLok solution to submit it to his/her local inspector for their approval.

I think DeckLoks are good brackets and Michael Morse, though headstrong and driven, has his heart in the right place. But I would be reluctant to use his detail when installing a deck until he has 3rd party testing to show the bracket system will meet the code requirement.

It's also important to note that Simpson tested their HD2AHDG brackets - now often used to secure guardrail posts to the deck frame - And they don't meet the deck lateral load requirement. That's why they engineered the DTT2Z. As far as I can tell the other major player in metal connectors (USP) isn't putting out any specialty deck brackets for post or ledger or deck to house connections. SO Simpson owns the market and can charge whatever they want for the DTT2Z brackets - and we have to use them.

Could you use MST's or such?

k

OK, what if your ledger runs parallel to the existing floor joists?

willsdad, Typically in a situation like the one you're mentioning, where you have to install a drag tie to a joist, but the joists are parallel to the ledger, you would install blocking to catch the tie. The blocking would usually have to be nailed to the floor diaphragm, which would of course present its own problems if the interior floor was already finished. In that case, a row of blocks running several bays into the structure, tied together with Simpson or equivalent strapping, would take the place of a joist.

Ladies Man,

When the ledger is parallel to the joists and the floor is already finished (making it impossible to nail the sheathing to the new blocking) we often use angle clips like A-35's to tie the blocking to the floor sheathing from below.

We use short structural screws up into the sheathing and floor, making sure not to go through the floor, of course, and pre-drilling if splitting is a concern. The screws don't have the same shear strength as nails, so we use multiple clips per block as necessary.

You still need to open up the joist bay to do all this, but you need to open it up to install the blocking anyway, and it's usually easier and cheaper to repair the drywall ceiling of the floor below.

k

I'm getting really sick of solutions in search of problems every time there is a code update...there are no stipulations as to deck size or height off the ground or deck shape? What is going to create these massive lateral lodes that now requires special bracketing to the inside floor joist system? Is there a worry that 30 people are going to pack onto a deck, stand against the house, and then simultaneously run to the outside edge of the deck and stop? So let's see... my house rim joist (even the one running parallel to the ledger), which is nailed and glued to the floor sheathing, has 16's nailed into it from the wall plate above, and is toenailed into the wall plate below (or sill plate as the case may be), is going to pull out of the house??? Come on.

This was great information Mike.

Thanks so much

Mike - Most decks that I see and that we build are attached a full 6-7 inches below the finished floor so as to avoid snow build-up at the door. This would make the diagrammed method impossible to construct. The other obvious problem is that for all the decks that are built as remodels (as opposed to new construction) there is often finished ceilings, electrical lines, plumbing, etc. in the way of doing this work. If this indeed becomes the code it looks like it will kill a lot of deck projects outright or force us to build freestanding (though next the code will probably evolve to require freestanding decks be anchored to bedrock). I think that they are looking to solve a problem that doesn't exist and will only help sell brackets while skyrocketing the cost of building a deck.

Yeah guys, in remodel work, you might occasionally have to cut into a finished (usually drywall, fer cripes sake)ceiling.

I'm still unclear why you couldn't cut a slot for some galvanized strapping and use that instead of hold downs, though.

k

I believe this lateral deck load provision applies to seismic areas as defined by the IRC

A reminder to those of you who mention not wanting to disturb finishes to get access to the framing I say if you are counting on the ledger and it's attachment to the house to support the load of your deck as well as resist any lateral loads you BETTER be opening up to at least inspect the framing unless you built that house you are making a dangerous assumption to assume that those that built it did it correctly or that it has not suffered any damage over the years since it was built to be sure it can support the loads you intend to put on it. If you do not want to do that then you are better off building a free standing deck, NEVER count on unknown existing structure to support anything with out first checking.

If you do not think a rim joist can be pulled away I have a few words of advice

Unless you know for certain how well a house was built to begin with don't take anything for granted. Sure it would be very hard, on a new house built to today's code to pull a properly nailed rim joist out of the structure if it was glued and proper nailed to 3/4 subfloor and then the bottom plate was then properly nailed though the subfloor into the rim joist as well but unless you built that house How do you know it was?

Just one example: Just last summer I was doing a remodel which included replacing all windows and siding and repairing water damaged sheathing.

On one corner of the house I found that not only was the rim joist falling away (2" gap from the floor joists) but the first floor wall was pulling away at the corner with a 1" gap at the top plate of the wall at the corner and a 2" gap at the bottom.

(The home owner should have known something was wrong when they had a 1 inch crack at the corner of the drywall inside but believe it or not they just patched it and ignored it.) Why did this happen? improper nailing of framing members combined with rotted sheathing and original plywood sheathing that did not span the wall to wall corner connections or the wall to plate connections. as well as 1/2 inch plywood sub-flooring not nailed to the rim at all.

Today the sheathing is a integral part of the framing structure to fight shear forces and a integral part of wall to wall and wall to platform connection. But many people do not understand this thinking is is just a covering over the framing and to nail the siding to.

So if a wall can fall away without the added force of a improperly supported and braced deck you can see why decks could pull a ledger and the rim board it is attached to away.

This house was built in the early 1960s and had many violations by today's code but was fine base on MINIMUM code at the time. But if it had been built by a good builder and not by one of the many shoddy subdivision hack jobs common during housing booms it would have not had any of the problems it had even with 1960s code.

SO as is often the case this is just one more change because of builders and remodelers that build to minimum code or less. Instead of building based on solid engineering. Must experienced builders can build a deck that will never put lateral loads on the ledger (baring a strong earth quake). But many shoddy builders/remodelers and DIYers need to be protected from them selves and are the reason for these code changes.

Larry, I too drop my deck surface 6 or 7 inches below the floor and thought about the drawing. There's nothing to say you can't install the through rod at an angle. Catch the lower 2 inches of the floor joist, the top two inches of the deck joist and a slight angle.

To others who have a gripe with the code - Do as I did and Join the ICC [http://www.iccsafe.org/]; now I can vote on proposed code changes. And the lateral load ties ARE code. And as soon as your code authority adopts the 09 codes, you too will have the opportunity to use the newfangled connection.

The solution is not looking for a problem - there is a problem. Stats show that more people are seriously injured or killed each year in deck collapses than any other single part of a house (that surprised me). Deck collapses are like car accidents - they happen every day but the national news requires a threashold of blood before it leads (think bus accident - 8 dead, Chicago deck collapse....).

And the lateral connection shown in the code is not 'required.' You are perfectly welcome to have an engineer design another solution that meets the performance standard (1500 lb lateral load resistance).

To me the brackets make sense. Also, for such a small invest ment I find it hard to believe any conscientious builder would not use the brackets.

I have my material currently ordered for a deck project and have submitted plans to the city. I was planning on using both the Maine Deck Bracket and two Simpson DTT2Z's for the new lateral load requirement. Used in tandem, this should meet the IRC requirements of Section 501.2, 502.2.2, 502.2.2.2 and 502.2.2.3.

Unfortunately, I am still waiting for my city inspector to make a ruling before starting.

Anyone used these products in this combination?

Thanks,

Rick

Leerb,

I think the Maine Deck Bracket and Simpson DTT2Z make a dynamite combination. I've used the Deck Brackets on a number of decks and like the flashability of them. Here's how I do it: http://www.deckmagazine.com/pdf/2007/0703/0703prod.pdf

I have not yet had a chance to use the two devices in combination. The lateral capacity of the DTT2Z isn't really related to how you mount the ledger for vertical / shear load. Your inspector may be questioning the difference between the code drawing where the ledger is in contact with the wall and how the Maine Deck Bracket holds the ledger off the wall.

The principle of the code configured lateral load connection is great - the rod connects the hold down devices from the house joist to the deck joist regardless of the ledger position. I believe they designed the connection to work this way so builders who like to use a stack of washers, Attach-A-Deck, Wall-2-Deck or other ledger spacing system can still provide a lateral load connection without having to switch to a different ledger mounting system.

I'll contact a guy I know at Simpson and get his take on the combination and post the information back here as soon as I hear back.

The codes do give final say to the local officials for better or worse.

Leerb,

I got a response from an engineer at Simpson Strongtie. His answer was in general terms about the code provision:

"The 2009 IRC R502.2.2.3 Deck lateral load connection detail functions by using a pair of hold-down tension devices, connected together by a rod in tension. Because this rod is in tension, there is no effect on having 3 inches of clear space between the ledger and the main structure."

The folks I corresponded with at Simpson Strongtie have concerns about the Maine Deck Brackets. Their concerns revolve around following the ICC-ES report to the letter. There are conditions in there that many people overlook when using them.

I am in the process of R&R of 200+ 2 story balconies, 12 x 4.5.

Originally they had cantilevered joists, they were back crudely to accept section of a "rim joist", the remaining joist were cut flush to the brick veneer on either side of the sliders. The rot is incredible.

Tying in with 2 dtt2z's helps me sleep at night, there really is no alternative

This is absolutely REDICULOUS! I live in PA and there are a-lot of Professional deck builders in my area who have been building decks for who knows how many years with no ledger failures or railing failures.

LEDGER FAILURES HAPPEN BECAUSE OF FLASHING ISSUES!!! READ ABOUT THEM

Now because Simpson Pays off everyone theyre fasteners are now code on every piece of a deck.

So the average homeowner is gonna have to pay 500.00 more for a 10x12 deck because we now have to cut open theyre ceiling, patch & repair drywall, re-paint, because simpson doesnt make enough money on lag bolts.

Also add these stupid things to railing posts that arent strong enough when theyre bolted inside a band board?!! B.S.

Theyre becoming just like insurance companies.

Making rules to sell product

This is great information on attaching these connetions to floor joists, what do you do when you are building your deck from your walk out concrete basement without having to make it a "free standing" deck? I would like to propose using 3/4" Hilti kwik bolts to fasten my ledger to the concrete foundation wall. The tension and shear values are well above the required 1500# required for the connection. Does anyone see a problem with using them?

Thanks,

Brian

RESPONSE TO BRAIN WATERMAN

I checked the Hilti Kwik Bolt 3 (KB3) ICC-ES Report and the listed specs from Table 10 "Hot-Dip Ganvanized Kwik Bolt 3 Allowable Loads in Normal-Weight Concrete" on their technical report (see link below.) It looks like the Hot-Dipped Galvanized Kwik Bolt 3 will work provided you have 3-1/2 in. bolt embedment in minimum 2000psi concrete (either solid concrete or fully grouted CMU. The tension limit is 1895 lbs.

So to make the lateral load connection, you would need to still transfer the load to two floor joists on the deck using the DTT-2Z or DTB-TZ connectors mounted to the deck joists.

As far as the vertical load, the Kwik Bolt 3 will support 2190 lbs with the same 3 1/2 in. embedment - BUT you still have to consider that the ledger board will be the limiting factor. You will likely have to position the bolts closer together than the shear value of the bolts allow because the wood won't be strong enough.

Of course, all of this ultimately needs approval of your local building official.

(http://www.us.hilti.com/fstore/holus/techlib/docs/4.3.5_Kwik_Bolt_3_Expansion_Anchor_(328-352)r021.pdf

Excellent discussion! Though I was aware of the 2009 IRC prescriptive design for deck attachment for lateral loads, there were some aspects that I didn't recognize until I read through all this discussion. (Great suggestion on the Simpson LTP4/LTP5/A34/A35 Framing Angles by KFC!)

Mike, in your first comment (back on May 29), you wrote "As far as I can tell the other major player in metal connectors (USP) isn't putting out any specialty deck brackets for post or ledger or deck to house connections. SO Simpson owns the market and can charge whatever they want for the DTT2Z brackets - and we have to use them. " However your main article lists the USP DTB-TZ as a competing bracket. I assume you edited the article after the original comments due to a newly released USP bracket?

I was glad to see the discussion of the Maine Deck Bracket(MDB) in conjunction with the lateral load brackets. I am working on a design to use the MDB bolted through the rim joist with a USP DTB-TZ or Simpson DTT2Z sharing one of the MDB bolts on the inside of the rim joist. The DTB-TZ or DTT2Z will provide lateral load support by connecting to an adjacent floor joist. An additional DTB-TZ will be needed on the deck side to prevent the deck from separating from the ledger.

It would be much easier for me to just install a pair of DTT2Z with threaded rod a shown in the above diagram and discussed in your quote from the Simpson Strongtie engineer. However, the reason for going to the MDB in the first place is significantly improved waterproofing. I'm trying to avoid the DTT2Z threaded rod penetration. This penetration will violate every layer of water resistance I've worked so hard to employ (chiefly, the siding and house wrap but also the Avantec sheathing).

I believe this will meet the intent of the lateral support code, though I'm not sure if I'm missing some aspect and of course don't know if it will pass local building official interpretation. Any opinions?

RESPONSE TO NOGAPS

Good catch on the post vs. comment. I can only go back in to edit the original post and can't edit comments. Hopefully that will change when FHB converts their website to another format.

Your last note "...don't know if it will pass local building official interpretation." is where the matter lies.

Without independent testing, using the Maine Deck Bracket to transfer the lateral load from floor joist to deck joist can be denied by a building official. The load ends up being offset from the web of the MDB and would need to be tested before Simpson or USP would stand behind the detail. But as long as the building inspector thinks it's okay - you're all set.