What’s the Difference: Circular sawblades with different tooth counts

Choosing a blade with the correct number of teeth for a particular job ensures the best performance from a circular saw, a miter saw, or a tablesaw.

For “What’s the Difference?” in FHB #201, I wrote about the significance of tooth grinds on circular sawblades. Choosing a blade with the correct number of teeth is equally important for getting the best performance from a circular saw, a miter saw, or a tablesaw.

Also Read: How it Works: Circular Sawblades.

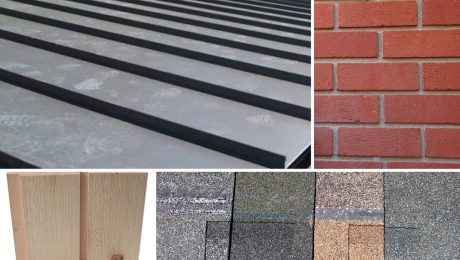

Circular sawblades come with a wide range of tooth counts, everything from 14 to 120 teeth. To get the cleanest cuts, use a blade with the correct number of teeth for a given application. The material being cut, its thickness, and the direction of the grain relative to the sawblade help to determine which blade is best. Perhaps the key factor to consider when choosing a sawblade is the desired result. A blade with a lower tooth count tends to cut faster than a blade with a higher tooth count, but the quality of the cut is rougher, which doesn’t matter if you’re a framer. On the other hand, a blade with too high a tooth count for an application yields a slower cut that ends up burning the material, which no cabinetmaker would tolerate.

Circular sawblades differ in cost as much as they do in performance. Blades range in price from a few dollars to more than $100. The blade design, the amount of carbide, and the quality of the carbide used in the blade influence cost the most.

Demo blades – 14 tooth

A blade with as few as 14 teeth cuts quickly, but roughly. These blades tear through even the thickest stock with ease, but their use is limited. If you try to cut thin sheet goods with a blade that has fewer than 24 teeth, you’ll pulverize the material.

Framing blades – 24 tooth

A general framing blade.the one that comes with most 71.4-in. circular saws.has 24 teeth and gives a pretty clean rip cut but a rougher crosscut. If you’re framing with 2x stock, where precision and cleanness of cut are secondary to speed and ease of cut, it might be the only blade you’ll need.

Sheet-good blades – 40 tooth

A 40-tooth blade works fine for most cuts through plywood. Blades with 60 or 80 teeth should be used on veneered plywood and melamine, where the thin veneers are likely to blow out on the underside of the cut, a characteristic known as tearout. MDF requires even more teeth (90 to 120) to get the cleanest cut.

Miter-saw blades- 80 tooth

If you do a lot of finish work—installing crown molding, for instance—you need a much cleaner cut that requires more teeth. Cutting miters is basically crosscutting on an angle, and blades with higher tooth counts generally perform best when cutting across the grain. A blade with 80 or more teeth offers the crisp miter cuts you’re looking for.

Photos by: Krysta S. Doerfler

View Comments

Hello,

Choosing a blade with the correct number of teeth for a particular job ensures the best representation from a circular saw. it is typically used to cut wood or wood composites.

On the other hand, a blade with too high a tooth count for an application yields a slower cut that ends up burning the material which no cabinetmaker would allow. It helps determine the speed, type and finish of the cut.