Just because it’s recycled doesn’t mean it’s green. Let me explain why I don’t use cellulose or blue-jean insulation.

Yesterday, a young builder came up to me after I spoke at the Atlantic Green conference in Charleston, S.C., and started talking about the new green house he was building. It had no-VOC paint, bamboo flooring, and insulation made from shredded blue jeans. And without thinking, I said, “So what’s so green about blue jean insulation?” The poor kid was expecting a pat on the back and what he got was a kick in his assumptions.

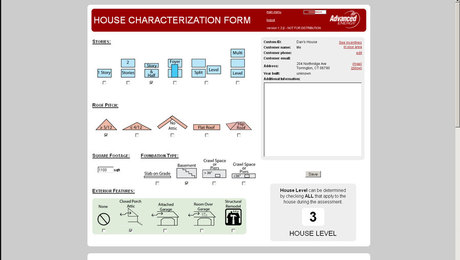

The whole idea about using a third-party green building verification system is to force designers and builders to look at the big picture, and to separate the “green-ness” of a product from its cost and marketing hype. The popular press is all in a tizzy about recycled-content building products. That includes anything bamboo, and über-groovy countertops, but the bulk of the things that make up a well-integrated green home are conventional products used with an unconventional attention to detail. It’s not about the silver bullets, it’s about getting the details right.

So what’s wrong with blue-jean insulation? Well, I have to drive past cotton fields here in North Carolina and they give me a strong incentive to choose organic cotton whenever I buy clothes. Even the work pants I wear are organic. Producing cotton is brutal on the land, far worse than wood fiber in every way, and processed cotton is a high-value commodity. Denim scraps diverted from the landfill? I think it’s more likely that they are diverted from a commodity stream that was already using them for another purpose, which still needs to be filled.

It would be fine if denim insulation was actually more economical and a better insulator than the alternative. But it doesn’t cut easily, so it’s more difficult to install correctly, and it doesn’t expand well to fill the cavities. It needs to be treated with fire retardants and insecticides and it can hold moisture. No wonder you won’t get a lot of green points for using it in your homes. It’s just not that green.

Cellulose retains moisture

What about cellulose? It’s just recycled newspaper, and that’s got to be green, right? Well that’s what I used to think, too, and you will get more green points for cellulose than for cotton. But I have seen what happens when cellulose gets wet inside a wall.

On two occasions, homes I have built with cellulose insulation had plumbing leaks. The moisture was absorbed and spread by the cellulose and it took days for the homeowner to notice. By the time we located and repaired the leaks, the cellulose had wicked up the water and become saturated. While the cellulose itself hadn’t mildewed, the studs, exterior sheathing and drywall were covered with mold. We removed the sheetrock and cleaned the wood and set the cellulose aside to dry. It was remarkable how long it stayed wet.

I have had trees fall on my roofs many times during ice storms or hurricanes. Fiberglass and spray polyurethane foam don’t retain moisture, it just flows right through and lets us know we have a problem. We fix the leak and move on. In homes with cellulose insulation I’m concerned about closing up a bunch of wet newspaper in my attic after a leak during an ice storm. I’m much more concerned with cellulose in walls than attics because most attics are both hot and well ventilated and foster better drying, but a winter ice storm could really lead to some problems.

Green building is about durability and performance more than it is about recycled content.

More on insulation:

Attic-Insulation Upgrade – Mike Guertin explains how to seal air leaks first and then blow in fiberglass insulation for an effective energy upgrade.

Does Fiberglass Still Make Sense? – Still a popular and affordable insulation option, fiberglass batts now share the stage with a variety of other products, including blown-in products and spray polyurethane foam. Here’s a look at some of the offerings.

Installing Rockwool for Continuous Exterior Insulation – Here’s a look at how the 2018 FHB House is wrapped in an exterior layer of mineral wool insulation to minimize thermal bridging through the building’s frame.

Choosing the Right Thickness of Exterior Foam – Rigid foam applied on top of the roof improves thermal performance dramatically. But to prevent condensation on the roof sheathing, the insulation must be thick enough.

Reconsidering R-Value Recommendations – Many energy-conscious builders rely on Building Science Corporation recommendations for insulation thickness. But falling prices for photovoltaic panels prompts another look.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Reliable Crimp Connectors

8067 All-Weather Flashing Tape

Handy Heat Gun

View Comments

Great post, Michael. Some good insights here.

Good points.

I think the real key thing to take away is what you said about they're not being any silver bullets.

I don't think there's going to be a silver bullet to any of our energy problems, but an unconventional attention to detail will be at the heart of it.

Great article. The last sentence hit it home, "Green is about durability..." In Vancouver, BC I've seen beautiful old homes being torn down and replaced with pre-fab and poorly made houses and leeky condos all for the sake of real estate trends. These dwellings will not last even 50 years and all of them will age poorly and eventually be torn down.

Talk about waste...

Good thinking,

Years ago, my Dad used fire-retardant cellulose insulation in a basement remodeling project. It later caught fire, and spread thru the house. When my Dad questioned the fire marshal about the "fire retardant" qualities, he was told that the insulation was fire retardant, when it was installed, but that insulation loses those qualities quite quickly.

So I look very hard at a lot of the claims for some of this stuff. Everyone seems to be getting on the ecological bandwagon.

And the recycled jeans, seems like a waste of resources. If it's good cotton why can't it be reprocessed into more fabric?

Finally someone that speaks up. I own a small company that makes wooden toys and we pride ourselves on being green, but I cannot stand green washing. I just yesterday picked up a black plastic brace (edging for interlocking stones) and it said "eco edge" or something of that sort. It pointed out that it was made from 100% recycled material. First of all, before green was on, they were already probably using recycled material, because it is most likely cheaper to buy than new rubber. Secondly, what is eco? Should it not take in consideration the entire life cycle of the item? You are putting plastic into the ground. The stones will just fall to pieces eventually and become part of the soil again. What about the plastic? Does it off-gas dangerous chemicals? Will birds or animals pick on it and make them sick?

If a company prides themselves in makeing a green product or being green, I urge you to look if they are ISO 14001, which is a management system which shows exactly how eco friendly a company is.

Best Regards, Hans (from ukoonto.com)

Hi everybody,

I'm just a little bit concerned about Michael's comments. The problem with wet cellulose isulation as described is not the use of cellulose itself, it' s just because the air and water thightness of the house was poor. People should simply not buy homes from those contractors. In Canada, it's supposed to be prohibited or totally not recommended to have plombing in exterior insulated walls so the flood problem should not be an issue and cellulose insulation is a recommended technique.

I'm a bit more concerned about the utilization of non-renouvelable-petrolium-based (isocyanates) spray foams, particilarly soja based spray foam because some food is used to feed house walls or roofs instead of feeding humans or animals. Corn grown in north america to feed cars with ethanol is another example of problems rising from what we call the ¨green economy¨.

Finally, based on Rob Yagid's article (Fine homebuilding, july 2009, No. 204, pp. 32-37) applying more than 4-6 inches of spray foam is a total waste of money (based on building science research).

I know you'll disagree with me but I can't let pass this one. Sorry everybody.

Hey Parentg6,

Thanks for posting your comments. You bring up some good points. With regard to the spray foam thickness/cost equation, more foam isn’t a total waste of money. However, lots and lots of foam may not offer the thermal performance you would think, just by adding up the R-values per inch. There’s more to the equation than just R-values and it’s important to do a cost/benefit analysis of each component of your home. (take a look at the article’s we’ve done on advanced framing techniques). You can not only save money, but you can conserve resources.

With regard to your concerns about turning food into insulation, you need not worry too much. The corn and soybeans used to create alternative forms of energy (and I’m guessing the polyols in spray foam) aren’t the same “food” you’ll find on the farm stand in town. They’re commodities. Commodity corn, for example, reflects the corn you’d eat only in appearance. Its kernels are extremely hard to eat, don’t taste much like corn and are extracted (grown) from the earth to be used as energy or it’s processed and into who knows what to be used in various ways (feed lots?). It's looked at less like food and more like a resource.

I have been screaming about the drawbacks of cellulose insulation for 10 years here in Saskatchewan (look it up on a map). We have huge moisture concerns in homes built in the last 10 years because of the increase in the quality of home building products. Moisture, over time, will absorb through gyroc walls and into the cellulose insulation - you don't even need a plumbing leak to cause a problem. I saw jean insul. demoed at our local home show 2 years ago. The demo cavity was packed so tight that there was no problem with gaps, but you could not poke into it with a finger. They had a sample on a table and I asked them what happened if the insul. got damp. They said nothing would happen. So I was a bad boy and spilled a bit of coffee on it. They had to remove it from the display for the rest of the show it swelled so much!!

Your blanket statement about cellulose not being green is just plain wrong. You are mixing up installation/regional issues with greenness for your comments on cellulose. It has to be one of the least resource-intensive insulation products to manufacture that outperforms fiberglass insulation. On top of that it is using up a "waste" product. In many areas of the US and Canada that get below freezing you would never be installing plumbing on an outside wall/ceiling for fear of freezing pipes (I do remember approx. 15 years ago when it was -20F all the way down to southern Iowa). Furthermore in the northern US and many parts of Canada fiberglass insulation is one of the worst insulations to use since 50% of its R value is lost when it is -20F whereas cellulose keeps its R value. Since you sound like you are building in an areas that does not experience freezing temperatures these issues are not applicable (especially if you are installing plumbing in outside walls/ceilings). So to make blanket statements such as you have done without your assumptions being stated is irresponsible.

Hi,

just a quick reply to Mr Yagid comment about corn produced for energy production. The problem is not the production of corn itself, it's the utilization of good land fields for the production of energy crops instead of animal or human foods(because good quality soils are reqiured for the production of corn ans soja production). Also for your information, corn grown for the production of ethanol IS the same corn grown to feed animals like pigs and cows(and not for humans). Corn production is an energy crop with the highest fertilizer requirements (which causes so much environmental problems). Nitrogen fertilizers are made with natural gaz (again not a renewable source of energy). So twice twice before using anything that simply labeled green...

Michael, Your blanket statements about cellulose insulation are just plain wrong. As tou might have seen already in previous statements, not everyone agrees with you. I once used fiberglass in our homes and rock wool insulation. I switched to a Borate stabilized cellulose product for the exterior walls above grade and in the attic areas. The reason being that it fills the cavity, is a recycled content that keeps from going to landfill waste and is a natural non toxic substance. The product we use will dramatically reduce air infiltration and inhibits mold and mildew, bugs hate it and it will not open flame burn because there is insufficient oxygen for combustion. I am a firm believer that a combination of insulation products should be and can be used in homes. We often use foam or kraft face fiberglass in basements.

Foam can be used for foundations, below grade and unvented areas with great success. However with out education of consumer installer and builder/remodeler of the ramification of any product and proper building science principles and interior and exterior water management, all products can be a disaster. In our region we would never place plumbing in exterior walls. Not all fiberglass or foams are perfect solutions either. I would much rather have cellulose in an attic area than fiberglass. In batt form it will not stop thermal bypass and in loose form is an airborne carcinogen. Not all foams are created equal and it is important to note and understand for the readership whether they are talking open cell or closed cell products. For you to make a blanket statement like this is disingenuous to your readership and irresponsible. I am a HERS rater, green verifier,remodeler, builder, and teach green building and the basic principles of building science. All insulation can work when installed properly and all insulation can be done improperly. Please try to keep the proper perspective when as a recognized expert you make such statements. Instead state an opinion and let it be known as such , not as the only solution according to you. Thank you for taking the time to read this and hopefully tempering your future commentary.

Sincerely,

Stephen from Indiana

What I am trying to get at here is to ask people to look critically at the claims made by manufacturers and to consider durability and effectiveness for the purpose above recycled content.

I also wanted to make the point that one of the big values of third party certifications such as LEED-h, NAHB-green, and the regional green building certification programs is that they push us beyond "silver bullet thinking" to a systems approach that values effectiveness and durability along with resource conservation.

I admit that I picked on Cellulose and Denim insulation because I thought I'd get a reaction. And I did point out that you will get green points for using these products in your homes. While I do believe that cellulose has an important role to play as an additional layer of insulation to be blown into attics during an energy retro-fit (after ceiling draft stopping) I think it is a mistake to use it closed up in walls and I won't use it in my homes when blown-in-batt systems such as JM spider and the like offer similar R-value at reasonable cost but with what I believe is better resistance to both fire and water damage.

The two leaks that I based this piece on did not involve plumbing in exterior walls. One was a slight headed pin in a radiant heated upstairs master bathroom floor which only leaked when the pipe was hot for an hour each morning. The leak fell on the drywall ceiling below it and ran out to and down the exterior wall and eventually dripped out at a window header below after the leak had been going on for several weeks. The other was a bad tile job that leaked only when the family used the guest bath shower.

I've been up in many attics that showed water staining from wind-driven snow that had blown in through 5-V metal roofing and soffit vents and melted on top of the fiberglass insulation. I pulled seven trees off my roof after Hurricane Fran and the fiberglass insulation was dry in no time and the shingle roof took 45 minutes to repair. (Had it been a steel roof it would have taken weeks to repair)

Water happens, we need to build with that inevitability in mind.

Every building site and set of circumstances is unique. I generally oppose calling products green (or not) and prefer that people look at the whole system using a third party green building certification system as they evaluate what makes sense for their climate, design and budget. For me this means no cellulose or denim insulation.

As a design-builder in Cape Cod, MA, where we have a good deal of water issues, I have to say you are all wet and number of your claims. The BigBoss is right on about cellulose. Fiberglass insulation is a thing of the past and the quicker everyone gets off that bandwagon the better. We spend our money on rigid insulation over the exterior sheathing to really eliminate any heat loss from the walls then blow in cellulose inside the walls. Spray soy foam in the ceilings and rafter spaces to eliminate venting the roofs at all (again no heat loss).The Bluejean insulation is meant for walls, not meant for ceilings our wherever you have it in the picture. Tight homes are good, and i venture to say if you're not building tight homes in Canada....well nuff said on that.

Any green is good, moving away from the old inefficient ways needs to happen now, not later.

Most plumbing leaks I see are a result of old age or freezing, not defective plumbing in new homes. I've never seen a frozen water pipe insulated with cellulose insulation. The frozen wall cavity is always uninsulated, or stuffed with fiberglass batting. After the plumbing is repaired, and the water soaked fiberglass is removed and discarded, superior cellulose insulation is packed solidly into wall cavity...no more freezing!

We routinely vacuum fiberglass out of attics because it proved to be perfect nesting material for rodents, bees, and insects. Just ask the housewife. After replacing the fiberglass with cellulose those problems are cured.

We recently pulled a cellulose sample from a home I insulated thirty years ago...the fire retarding qualities were present so anyone who claims otherwise is suspect. Michael Chandler's story only serves to distort the superior value of cellulose over foam and fiberglass. Informed consumers choose cellulose for economy and its effectiveness at stopping heating and cooling losses. Nothing beats it.

Foam is expensive so not cost effective. Federal law requires the installer disclose to buyers that foam shrinks up to 3%. That much shrinkage makes for a defective, overpriced and under insulated wall. In our area foam is so expensive only an inch, or so, is sprayed into walls. I can't imagine the bill for spraying eight inches into an attic.

Fiberglass blown into an attic loses half it's R-value during cold winter months when the insulation is most needed. Cellulose has the ability to stop air infiltration which fiberglass does not. The difference is remarkable. Much of you work is blowing a cellulose blanket over fiberglass to to correct the leaks. Our customers are always happy with the price of cellulose and more importantly, the energy savings and comfort they experience over fiberglass and foam.

Truth is, contractors who prefer blow in fiberglass for attic insulation choose it because they can short the homeowner on the number of bags they blow in..fluff up the fiberglass and make a hidden profit. Of course the fiberglass settles and years later we install cellulose, allowing for the slight settling it realizes by quoting two depths..the installed depth and the settled depth. Much of our attic work is insulating attics that have already been insulated with fiberglass, two, three, and sometimes four times previously. The home NEVER needs insulated again after we complete our cellulose work.

Back in 2001 when we started an addition to our existing house we looked into alternative insulation. I wanted to stay away from cellulose because years ago I had seen it take down a ceiling after getting wet from a leaking roof. I liked the idea of the cotton mainly because I despise working with glass. No matter how much protective gear you wear some of the glass always works its way into your skin. The problem is cotton costs over three times as much as glass. I don't care how GD green it is - at that price they can stick it in their ear.

I like the debate this has opened up, but the last sentence of the article seems backwards to me.

"Green building is about durability and performance more than about recycled content."

Green building refers to building sustainably with the local ecosystem. That would include repurposing items. Many of these repurposed materials would be less than ideal for the application. They may be more sustainable though. There are many conventional methods that may perform better and just need some tweaking to make them more environmentally-friendly. I agree it may be wiser in many cases to choose a less sustainable material because of added durability and performance. However, green building is not about durability and performance over recycled content. By definition it's not. While we should be skeptical of "green washing", it is not cheaper to use post-consumer recycled content at this time. The material has to be reclaimed and processed again. Coke and Pepsi buy new aluminum for their cans; it's cheaper. They encourage you to recycle though. Ironic, to really be re-cycling, we must also buy recycled, otherwise it doesn't cycle back. I'm weighing out materials to choose for my own home. This article with the debate is very helpful. I live in an area with a lot of moisture. Performance is going to be a major consideration of mine, possibly outweighing a supposedly greener material. We just can't throw around terms and change definitions because it sounds nice at the end of an article. If it works better but is less "green", then just say that. I still like to hear your perspective and concerns with the materials as well as everyone else's.

I like seeing someone debating the greeness of things. Insulations long term savings of resources certainly outweighs any lack of greeness at the manufacturing end. I don't think the water issue is a good enough reason to justify using fiberglass though. Plenty of rot has occurred in the presence of fiberglass insulation. And, it doesn't seem to do a very good job at it's intended purpose. Even in a fully sealed chamber air currents within itself keep it from competing very well with foam or cellulose. Since perfect air sealing in a building is not likely especially after it is decades old why use something that does nothing to prevent air infiltration. Fiberglass is not a green material in my opinion.

I've got dense packed cellulose and rigid foam board in about half of my house. There is no question in my mind that they, alone or in combination, are the best value in insulation. They are reasonably green since the energy saved is so great. I have fiberglass batts in about 1/4 of my house and regret putting it in.

I think that SIPs are probably the greenest way to go when all things are considered.

Michael Chandler begins his story by saying, "Just because it’s recycled doesn’t mean it’s green." He spends the remainder of his words promoting fiberglass and denouncing cellulose without ever making a case for cellulose not being "green". He's just a front man for the fiberglass industry. Fact is, fiberglass uses massive amounts of energy to manufacture. Cellulose does not. This is a straw issue used by the fiberglass industry to distract from the real issue which is...fiberglass is pitifully poor insulation at any price! I wouldn't put it in my home if it were FREE!

The next silly argument, "We took our ceiling out because of water damage and the cellulose was damaged too." No kidding? What else was damaged? The carpet, the furniture,clothing, and anything else that was water soaked? Had the attic been insulated with fiberglass even more water would have soaked the contents of the house instead of being held back by the cellulose. I guarantee the nasty wet fiberglass wasn't recycled and re-installed in the attic. A knowledgeable consumer would have replaced the fiberglass with cellulose, guaranteed to stop water pipes from freezing, unlike fiberglass.

It's proven that when two homes are insulated with the same R-Value in both ceiling and walls, the one with cellulose will be 27% more energy efficient as opposed to the fiberglass home. If the fiberglass were free the higher heating and cooling costs would make living in that house much more expensive than the cellulose house. Contractors who prefer fiberglass do so only because they can make more money using blown fiberglass...they cns hor the customer many many bags...which is their hidden profit. Even if the homeowner measures the depth they cannot detect they were shorted...you see, the fiberglass is fluffed up so it's not as dense and required for the stated R-value. As a result opf the fluffing fiberglass will settle even more than it would had it not been fluffed up to cheat the customer.

The bottom line is that most homeowners made insulation decisions based on the information fed them by high pressure fiberglass and foam salesman. Inferior products take extra-ordinary means to get consumers to buy. Fear tactics about cellulose is the bases for many fiberglass and foam sales. Based on merit, value,and energy conservation, cellulose wins hands down. That's why the cellulose market continues to grow and homeowners discover the remarkable savings over fiberglass and foam.

What is your definition of "Green" I am an insulation contractor and I have done almost everything. I recently installed the recycled denim bats for sound and it was rather difficult and pretty expensive. They are very heavy and will not stay up in the stud bay. We had to staple them in every bay. I would be very concerned about them staying up in the exterior walls. They were also very hard to cut. So I lost money in labor. We even found a "snack" (sunflower seed) someone may have left in a pocket. Ha.

Recycle content and renewable resources are great, but as we look at the big picture, coupling not just manufacturing but performance of the product is very important.

ALL fiber insulations (glass, cellulose, cotton, rockwool, etc) are not air tight. Look at the perm rating. And look at the EFFICIENCY of the product. Everything has R value, but how efficient is it? (Efficiency really is the key to overall performance). Can it maintain it's R value with: wind, vapor, heat, cold, and continually changing vapor drives?

I do like cellulose over fiberglass for health reasons (my personal feelings based on many scientific articles) but that is just me. An I don't care what anyone say about no rodents in cellulose, I've seen it many times.

Spray foam is more expensive, but really is a superior product. It will pay back over about 5 years. There are many other benefits to it also. Why else is your refrigerator, freezer, cooler and every cold storage facility sprayed with closed cell foam? Nothing else can match it.

Just remember. Think about the big picture and overall benefits when deciding on what is "green." It might surprise you.

Folks _should_ think about displacing food. While the particular varieties used for fuel and crops are not all yanked from the mouths of hungry people... The farmer makes a choice as to which variety to grow (edible vs industrial) and where to sell it and this choice is driven by demand and that shows up as a market price (more or less). I don't have an answer, sorry to say, but it is not as simple as "it is from a plant so it is green."

Ditto for using "waste" fibers. They are not really waste most of the time. They have a market and distributors and prices etc. Not really what we should be calling waste.

I'd like to know how rockwool rates in the great green insulation race. We use this insulation most of the time for the reno work we do. Aside from being the standard for construction where acoustic isolation is primary (i.e. recording studios), it has excellent heat insulating qualities, its combustion temperature trumps pretty much anything else out there, and it also repels water.

Installation of this material still requires the use of masks and gloves, but it's way better than fibreglass bats!

That said, I really don't know anything about the manufacturing process... it is made of rock, so can I assume that it's relatively "green"?

Hey Folks..

As I'm sure you are all aware it comes down to proper design and materials use, I did disaster repair work in northern Michigan for 15 yrs. - Wind Water Fire and Ice. The fact is: - They all get wet,they all get heavy. Some swell and they all come from somewhere.

The fact is that Cellulose is the only

truly green and sustainable insulation material available,- The way Western fibers does anyway..

No offense intended but; This article is a mute point. Only one FiberGlass users rather limited perspective and by no means anything new. I feel that the comments make alot more sense than the article.

I've done redevelopment, Historical preservation. There are uses for each of the materials mentioned.. BUT like Tyvek Ice and water shield, Venting, Poly, Elastomerics, etc.etc.etc. - ONLY in the proper Context. Or we end up in the mold growing business..

One measure of green is how much energy does it take to make it compared to other products. If it is already a by product of another process is is now saving energy that would be used otherwise. If it takes more additional energy to make it into its final use then that must be accounted for. It is not green because it is recycled in my view.

Then we must get down to other characteristics. Cost to install, efficiency, other desirable features like sound proofing, water absorption, ease of retrofit etc. Greenness is too simple minded a term, and definitely not easy to compare. The rating system is deficient if it only compares recycleability!

I'm interested in this point about detecting leaks through foam insulation. I've read this claim by demilec, icynene, etc that water just passes right through so you find a leak right away.

But I've heard anecdotal evidence to the contrary - it's just a big sponge and destroys hangs on to a huge amount of water.

What's the deal on this? This is a main reason we haven't done a hot roof from foam.

Grandizer

I've had a couple of roof leaks with Demelak roof insulation and it came right through, made the ceiling wet, we fixed the leak and there was very little dampness captured by the foam.

do a test in your bathroom sink. take a small cube of spray foam of the type of product you are thinking of using and leave it in the sink for a couple of hours with cold water dripping on it to simulate a roof leak. now do the same with cellulose or fiberglass. let the samples sit for an hour or two and see which has taken on more water...

I like Demelek a lot but Icenene is much cheaper in my area so I use Icenene since I'm spraying 8" and it adds up. (my last roof @ 2,600 sf, 8" thick cost me $5,700) I use a blown-in-batt fiberglass system, not regular batts, in my walls. If I had to stop using foam in my roofs I would consider cellulose but would probably go to Spider fiberglass but it would be a difficult decision.

The conversation has gotten a little heated here. Just to be clear I am not a "front man for the fiberglass industry." I'm a small builder trying to make a living building homes I can be proud of with a gang of employees who enjoy working together. Someone from the cellulose industry did recently offer to insulate one of my homes for free and I turned him down.

I don't accept any kickbacks or subsidies from any manufacturers ever. I make a decent living building homes and I like being able to write about the trade from an independent perspective.

We're considering "foaming" our attic roof to improve our insulation in our 1876 home. I've seen some pretty compelling demo's of the benefits of this over adding several inches of additional insulation to our attic floor (which would present its own problems.

However, another contractor came in and claimed this was crazy. The back and forth in this comment thread isn't really helping. Is there a reliable, independent, source of information on the topic? Obviously, our location plays into it (Canada has different needs than MD or Arizona), so if that is included as well all the better!

I know my place has a lot of issues regarding insulation and sealing, and the most "green" solution for me is the one that minimizes my energy bills!

A good source of information on foaming the roof of an 1876 farmhouse would be the Q&A section at http://www.GreenBuildingAdvisor.com

There will be a lot of different opinions and concerns. Your location is critical and the ability to reach the entire envelope of the attic is crucial when applying spray foam as is the risk of accidental damage caused by foam dripping onto siding, roofing, sidewalks and even living spaces through gaps in the envelope. It can be very damaging esp to porous and damp items such as siding and roofing and concrete. (Think foaming Gorilla Glue) You will want to completely encapsulate the attic area if you go this way and that means exposing and embedding the top plates in foam and making a continuous barrier between the top plates and the roof out of the foam.

Cellulose might look pretty good in this application especially once you look at the price. Again, a lot depends on your geographical location.

When Michael Chandler writes, " I use Icenene since I'm spraying 8" and it adds up. (my last roof @ 2,600 sf, 8" thick cost me $5,700) I use a blown-in-batt fiberglass system, not regular batts, in my walls."...

...several questions come to mind. For example, when Chandler says Icenene coasts him $5,700.00 for 2,600 sq ft, 8" deep, is that the cost of the foam in in the drum? Or is it the cost installed, including labor, fuel, time, etc?

The bigger question is...what does that job cost the customer??? Cellulose is cost effective and has a better R-value than the overpriced Icenene foam Chandler is hyping.

In the United States, Federal Law requires insulation contractors to inform customers, IN WRITING: that Icenene foam shrinks up to 3%. That shrinkage makes Icenene foam about as poor an insulator as foam can be.

When a home with Icenene foam burns, the foam gives off deadly gasses. The victims are more likely to die from the foam fumes than from burning.

What exactly are the "blowing batts" Candler speaks of? I'm guessing it's chopped up fiberglass created to market the worse insulation on the market.

Air infiltrated fiberglass insulation in the walls and shrinking foam in the attic will never insulate as well or as economically as cellulose.

You consumers trying to decide...keep in mind it is your responsibility to feret out the truth about insulation. You'll never learn the truth about cellulose listening to a foam or fiberglas salesman (or contractor). Go to: http://www.cellulose.org/HomeOwners/

You will live with the results of your willingness to get involved. Be an informed consumer and the choice is clear. Good luck.

I'm just glad to read something sensible sounding about green building. It's refreshing. We've gone green crazy and it doesn't seem like anyone is stopping to check the adverse effects of some of these products or ideas. Or, as mentioned, to consider whether it's green at all.

I couldn't have made the points Michael does any better. Durability and Performance may be achieved through different means by different designers and builders in different locations. The open discussion about building materials and practices that get us to Durability and Performance is valuable but sometimes confusing. I learned a couple new perspectives reading Michael's blog and the string of comments from readers.

There will never be a definitive prescriptive approach to material selection and construction practices that leads to a green house. After I've completed a 'green' house or remodel I learn something new or think about something a different way that makes me question whether we did the best work we could have from design through construction. Maybe someday someone will build the 'perfect' green house that we can all agree 100% with, but I doubt it.

Mike Guertin, you did not identify which "points" you believe Mike Chandler did well on. I read his, and then your, blind acceptance that foam has some superior qualities... none that he, or you, stated. What he did say is not supported by scientific proof. It's not a matter of "opinion" when comparing cellulose to foam, the facts are there if you care to truly discuss the facts and not dilute the "discussion" effort to a "difference of opinion" which is about the strongest argument the foam industry can offer to induce consumers to overpay for overpriced, under performing, shrinking, open cell foam.

I don't think "durability" is a major issue with insulation. If so then use fiberglass. it is more durable than open cell foam and much much cheaper. Most reasonable folks recognize that if a roof leaks or plumbing leaks, drywall will be damaged and furniture will be damaged. Replacing insulation isn't the deciding factor when insulating for thermal efficiency. Wallpaper is damaged by water leaks, as is the paint, carpet and most everything in the house with the exception of the bathtub. So what? Is the plan to replace all the water damaged items and components in the house and save one hundred dollars by using foam in the attic instead of cellulose...at twice the price and for less energy savings???

Of course there is a definitive approach to cost effective insulation.. simply choose safe, fire retardant, air sealing cellulose insulation in both ceilings and walls. Let's give credit where credit is due.

From my experience, as a practical matter, you foam boys talk a lot about installing foam in ceilings but the fact of the matter is, it's so very expensive most consumers reject the notion as not practical and certainly not cost effective. Those who do insulate their walls with foam aren't aware it shrinks because that fact was hidden by the salesman. They do eventually recognize they paid twice the money for wall insulation and ended up with fiberglass in their attic. That bait and switch combination is much less efficient than cellulose in both walls and ceiling. If you don't believe me put your money where your mouth is. Lets build two identical houses, do blower door tests and I'll insulate the one that leaks air the most. You do the other house and then let their respective energy usage data reveal to all, that cellulose will recover the investment and foam will continue to cost money and worse yet, if it is combined with a fiberglass insulated attic, like most are, it will have a higher energy usage than the all cellulose home. Let's do it.

Response to "CelluloseFacts"

Normally I don’t respond to the type of derisive commentary exhibited by folks like “CelluloseFacts” but the potential to cause confusion is such that I feel like a few items here need to be addressed.

He asks what is included in the cost I recently paid to insulate a 2,600 sf roof with 8” of foam. The $5,700 price quoted is what I paid my insulation subcontractor for a completed job inclusive of all material and labor costs, insurance, taxes, fuel and his profit. The price to the home owner was included in the price of the house and I do include a profit in that, 40% of which goes to my employee profit sharing plan.

Re: my “silly argument” about durability. He says that if the roof or plumbing leaks there will be huge damage and the insulation is an insignificant factor. The reality is that many leaks in homes are small and persistent and by no means catastrophic. In many cases if the insulation allows the leak to be detected it can be repaired before major damage occurs, often well before drywall or even paint needs to be repaired. As noted many roof leaks such as those due to drifting snow or wind driven rain never get detected at all, they simply get the insulation wet and later it dries up. Cellulose in my 30+ years experience holds onto that moisture and allows it to accumulate in the building far more than foam or fiberglass.

He brings up the issue of fire retardant qualities of cellulose and the toxic smoke of burning foam stating that “the victims are more likely to die from the foam fumes than from burning” but the reality is that foam needs air to burn and most foam is installed in sealed attics and enclosed wall cavities. By the time the fire opens the house up enough for the foam to burn the fire is already advanced to a significant extent. Both fiberglass and cellulose attic assemblies require ventilation. Fire can run up the building siding and in through the soffit vents and across the attic ceiling involving the entire home without igniting the insulation. A foamed roof assembly has no soffit or ridge vents to provide access from a brush fire or to fan a fire once it has penetrated the attic. It is much more resistant to fire than a ventilated cellulose or fiberglass roof assembly. I don’t use fiberglass in my ceilings either, at least we agree on something.

He accuses people like me of using “bait and switch” tactics to trick homeowners into blowing foam in walls but using fiberglass in the ceilings. Had he actually read my article he would have noticed that I use micro filament “spider” blown-in-batts in my walls and spray 8” of foam on the underside of my roofs. I don’t know of any builders who use foam in the walls but put fiberglass in the attics, makes no sense to me either. I think this is what is called a “red herring” or a “straw man argument”.

He wonders what are these “blowing batts” and guesses “it's chopped up fiberglass created to market the worse insulation on the market.” The blown-in-batt I use is called “spider” and has fibers much smaller than the fibers seen in common fiberglass batts, which I don’t advocate that anyone use in walls either. These “micro-fibers” are blown out of a hose and sprayed with a water based adhesive while they are in mid air. They adhere to the framing and fill all the gaps behind pipes and wires leaving no air gaps as might be found in a conventional batt installation. Once dry they form a matt that has the same R-value as open cell foam, is formaldehyde free, firm to the touch but soft enough to snake a wire through and is not itchy. For double stud type walls that are thicker than 6” we staple a mesh to the face of the studs and fill the wall with insulation with out the water based glue to avoid trapping moisture in the walls.

Most humorous of his allegations is that “that most homeowners made insulation decisions based on the information fed them by high pressure fiberglass and foam salesman. Inferior products take extra-ordinary means to get consumers to buy. Fear tactics about cellulose is the bases for many fiberglass and foam sales.” I can only imagine how LOW PRESSURE this guy must be on a sales call…

I realize that there are many very reputable, green and high performance builders who have had great success for many years with cellulose insulation in walls as well as in attics. I don’t feel that it’s “not green” like I do about blue jean insulation. I just know that it’s not for me. And I feel very strongly that I am not cheating my customers by making this decision.

I don't intend to appear derisive to you Michael Chandler. I work for a living and am just trying to make sense out of your claims. I don't hire sub-contractors so I don't mark up their work so I don't know the pricing structure you talk about but your foam still appears to not be cost effective for the homeowner, which is my concern. The homeowner pays double for a less insulated home.

I also have a problem understanding the 8" depth claim you make. The photo shows a roof assembly sprayed with foam but the trusses don't appear to be 2x8". I see a couple 2x8" boards but most look smaller. Maybe it's the angle. Is the photographed "attic" the actual one you insulated to an 8" depth? You mentioned "open cell" foam. What R-value do you claim in your "8" foam attic"? Open cell is often used for retrofits and closed cell is used on new construction open spraying, the reverse of your choice. The open cell is less expensive and has a lower R-value. Do the homeowners understand their choices when they pick the lower R-value foam?

Since you are only talking about a small water leak then consider you are paying DOUBLE (or more) than a cellulose insulation job would cost for the privilege of possibly containing a small puddle. Cellulose will do that. It absorbs and gives off moisture daily. True water damage occurs as a direct result of fire hoses, wind/storm damage, lightning strikes, and frozen water pipes that thaw and leak. Foam will not spare the homeowners' contend and structural damage in those scenarios. Again, it's hard to rationalize foam and fiberglass at twice the price for the rare occasion it might save re-insulating a small area of the ceiling (or wall). Truth is, most walls freeze and leak water because the fiberglass does not adequately insulate them from cold air infiltration. I routinely remove both blown and batt fiberglass insulation from wall cavities after the plumber repairs the pipes. I re-insulated with solidly packed cellulose and there are no more frozen water pipes. It's amazing.

I stand by what I said about more folks dying from the fumes of burning foam than do by the fire itself. Check the records and see for yourself! Instead you want to argue how a fire develops in a burning home. I don't think you are qualified to conduct that discussion so please just examine the history and records available to you. My experience is the vinyl siding melts before it chimneys air to the attic. Usually when that happens the fire was from an outside source.

You are wrong, cellulose "assemblies" (whatever that is), don't require "ventilation" so please don't confuse your facts and associate cellulose with fiberglass. Fiberglass requires house wrap to help stop air infiltration. Foam shrinks as much as 3% so you can compare foam to fiberglass when talking about its inability to seal air infiltration. Cellulose prevents the air infiltration fiberglass doesn't. Since it stops the moisture laden air there is no moisture to condense like in drafty fiberglass "assemblies". Slope ceilings, for example, can be packed solid with cellulose (just like walls) with NO problems.

Sorry Michael Chandler but your "blowing batts ("spider" fiberglass), like all fiberglass insulation, is a

"Confirmed animal carcinogen with unknown relevance to humans" and "reasonably anticipated to be a human carcinogen, based on sufficient evidence of carcinogenicity in animals." Did you share that important information with the lucky homeowner before contaminating their walls?

I did read your article. I was talking about the bigger market, which includes the home retrofit segment. The sales routine is to talk up the "benefits" of foam and sign a contract for foam in the walls but then the homeowner is given "free" fiberglass for the ceilings. Most of the insulation they get is fiberglass but they paid double the cost for the "privilege" of having foam retrofitted to their walls. Sounds like bait and switch to me. Are you aware of the industry-wide practice of fluffing the blown attic fiberglass in order to increase profits? By fluffing his insulation, the fiberglass contractor can pump the fiberglass up to the quoted depth and still use much less material. The many bags of blowing fiberglass he discretely does not install represents a fat hidden profit. I'm sure with all your experience you have heard of the problem of fiberglass fluffing? By the way, what R-value are you claiming for "open cell foam" and your cancer causing spider fiberglass? The spider MSDS states an "up to" value, what can cause spider to not achieve the "up to" R-value number?

What is "humorous" about the problem of high pressure salesmen? How else can the salesman of an over-priced and under-performing product induce elderly people to pay double? So that problem is a knee slapper for you?

I'm still waiting for you to tell us what is "green" about foam (or fiberglass). "Green" is a marketing tool these days. The term is about as useless as calling a food product "organic". Now that these terms have legal definitions, they aren’t so "organic" or so "green". Petroleum based foam is green in what world? Fiberglass is fuel intensive to produce so its rough on the environment too. In spite of that reality you are content to call them "green". Now that's a knee slapper Michael Chandler.

I'm curious why cellulosefacts has not provided a profile. I put my name, face and sometimes faulty reputation behind my statements. I think it only fair to know with whom we are discussing issues with. (is it 'whom' or 'who'- I always forget)

Mike, I'm sure your buddy appreciates your effort to support his fallacious comments about cellulose insulation. I commend your loyalty. In that both he and you have strayed from the facts about the subject why stray even further getting into some personal tangent about "profiles". This issue is too important to readers to reduce it to anything less than a finding of the facts. That means fiberglass facts, foam facts, and cellulose facts. Agreed?

Michael Chandler cites open cell foam as being "durable". Stretching even more he claims open cell foam "blocks water". The open cell foam I am familiar with is paramount to a sponge with regard to water. Is it possible Michael Chandler is confusing open cell foam with the much more expensive "close cell" foam? That's a common tactic amongst the cheap foam peddlers...associate it with the too-expensive foam and it's better laboratory tested characteristic as compared to the much cheaper open cell foam. Do you see where the homeowner and reader might be confused? If Michael Chandler (or you) intermingle the characteristics of two different foam products, referencing both as "foam" the reader is duped into a false belief about the implied "qualities" of the cheaper foam product, and perhaps, even the very expensive one. Do you feel any sense of responsibility to not contribute to the confusion?

As for "durability", are you aware of any scientific studies that proves Michael Chandler's claim of "durability"? Since foam shrinks after installation (hidden away from customer sight), an since foam loses R-value as it ages, what is it about open cell foam you two are declaring "durable"?

I'm not interested in "discussing your self proclaimed issues". What would serve the reader and anyone interested in gaining knowledge about insulation before taking the plunge is to state the facts correctly and not hide the truth by bantering "issues". The information I have (facts) is directly from the manufacturer of the various foam and fiberglass and cellulose products. You can readily read the Material Safety Data Sheets (MSDS) required by our Federal Government on ALL products and if you absorb the content you too can state facts instead of "issues". If we state the facts about each product I'm betting a new set of issues will surface once the facts surface. For example, credibility, value, return on investment, all the things that an informed buyer of any product wants to know.

One more issue to consider that probably wouldn't occur to a builder or homeowner while in the process of planning for the construction of a new home is that the building will not last forever. What is done with any particular construction material at the end of its useful life span is also a totally valid factor to consider when evaluating how green a material may be. When a building insulated with spray-applied foam insulation is demolished, will it be practical to remove the adhered foam from the lumber, the copper wiring and plumbing pipes so that they can be reused or recycled or will it be so difficult to separate the materials from the foam that the whole thing will go into the landfill?

CelluloseFacts - Any chance you can offer up some sources for all of these facts that you are throwing around? This is not a personal attack, but without data to back up your claims they are just as arguable as you are claiming Michael Chandler's and Mike Guertin's to be, no?

As a homeowner, I appreciate the good information included in the debate below. And, as a producer of FineHomebuilding.com, I understand this is a hot-button issue. The last few comments, however, have become increasingly heated, insulting even, so they’ve been removed. Debate: good. Attacks: not good. It’s a good idea to deliver your points and counterpoints respectfully, without sandwiching them between subtle (or not-so-subtle) jabs, which are sure to raise questions about the value of the argument.

Let’s keep the comments respectful so homeowners and pros alike can stay focused on interpreting the information and come to some conclusions about the benefits and risks of the various types of insulation.

Thanks, everyone.

JFink, a reliable source for cellulose information is:

http://www.cellulose.org/CIMA/

I provided that information in my first post I believe.

Also, Oakridge National Laboratory does research for the Department of Energy, and others. I don't think they dispute anything I have shared. They are a great resource for factual information about the insulations they have tested. They are doing research to recognize the "whole wall" R-value, which includes the all-important air infiltration parameter not usually shared wih consumers. You can find their work at:

http://www.ornl.gov/ornlhome/energy.shtml

Theri material on a more scientific level so not fast reading for us common folks.

The details I offered with regard to packing slope ceilings (and walls) with cellulose is a common practice amongst experienced cellulose installers and is also documented on one (or more) web sites of cellulose manufacturers. Seal the cavity with cellulose and moisture carrying air won't be a problem. The small amount of moisture that cellulose "breaths" has no negative consequence on the quality of the insulation work or the home. If this were not true we could not retrofit older homes with cellulose (they don't have house wrap). We tighten them up nicely and reduce heating and cooling costs as much as 40%.

I believe the only arguments I've heard against this technique was from the fiberglass roofing manufactures but they haven't showed any research to support their claims. Keep in mind they also manufacture the fiberglass insulation who at one time manufactured asbestos, the other carcinogen. When they lost their cancer lawsuits they filed bankruptcy. I've read that fiberglass insulation is a worse carcinogen problem than asbestos ever was. Do you want to trust a giant international corporation who filed bankruptcy to avoid asbestos claims?

The two Michaels (Chandler and Guertin), keep repeating the same erroneous claims about foam being "green". They even redefine "green" to include "durable". I don't believe Chandler's coined word, "durable" is defined by those who classify building materials. Is Chandler campaigning to change the official definition of the word green as it applies to building materials? Then concrete and steel are green too.

Also, the Michaels loosely use the word "foam" without discerning which they are speaking of, (closed or open cell), two different animals. Consumers should be made aware which the writer is discussing. The cost of close cell foam is even higher than the over-priced open cell foam. The close cell foam is in fact a barrier to water and has a significantly higher R-value than it's poor cousin, open cell foam. When Chandler, and others banter the word "foam" around, the reader can easily be mislead to believe the poorer quality foam possess the characteristics of the premium foam product, which of course, is too expensive to fill an eight-inch space with. It's simply not cost effective to do so. Consumers have a right to know that don't you think?

If Michael Chandler wants to block the truth by having my posts removed then so be it. But please don't break my kneecaps, I work every day.

Thanks for the links, CelluloseFacts. I agree that ORNL is a fantastic resource, but years of homebuilding-related journalism have taught me never to rely on the word of a trade association such as CIMA. We live in a world where these organizations play fast and loose with their information - third party testing from folks at Buildingscience.com, GreenBuildingAdvisor.com, the building science department at UMass, and as you said ORNL - are all more reliable sources for this type of information (if you ask me).

Regardless, the discussion has gotten a bit off topic. There is always going to be argument over what products are "green" and why. I would not be surprised if Michael Chandler disagreed with Joe Lstiburek, or Joe Lstiburek, disagreed with Alex Wilson, or Alex Wilson disagreed with Martin Holladay. These guys are all seasoned vets in this area of building, but green is a point of view in some respects, no?

The Cellulose Insulation Manufacturer's Association, at: http://www.cellulose.org/CIMA/ is as reliable as they come. I don't know of any others "like them". CIMA provides solid reliable consumer and technical information to homeowners, builders, and anyone interested in having a strong understanding of cellulose, fiberglass, and foam.

If you believe any of their information is less than credible please point out your concern. I always invite, "please prove me wrong", no one ever does with regard to the CIMA data or the Oakridge Laboratory research.

I did spend some time browsing the web sites you provided, each tried to sell me books and videos and get me to join and be on a mailing list. The sites you provided are clearly selling third-party products. (Did not check UMass)

No need to argue. The science is in. Foam is overpriced and uses 64 times as much embodied energy to produce as cellulose insulation. Cellulose has a higher R-value than open cell foam and is half or 1/3rd the price. Cellulose is rodent resistant and fire retardant and is a much better sound deadener than fiberglass, which loses half its R-value in cold weather...since it has a much lower R-value to start with it has none to spare. Cellulose stops air leaks fiberglass doesn't.

It's not really an argument when one product,like fiberglass is so inferior. it' just an embarrassment to the ones claiming it's fit to put a carcinogen in someone's home. Close cell foam is a great insulator but is too expensive to fill a wall cavity or attic. Cellulose does quite nicely and is economical and truly green. There is nothing to argue about.

As for your list of names...well, whether they disagree with each other or not is of no concern of mine. If any of them disagree with the facts about cellulose insulation then I'll gladly discuss their beliefs with them and anyone who wants to read along.

As for your premise that "green is a point of view", I must point out the term "green" is totally meaningless if builders are loose with the term and describe foam and fiberglass as "green...claiming they are "durable" so fits their personal definition of green. How silly is that?

"Organic" meant something different before the term gained a legal meaning. Now far too many growers find ways to define their product as "organic". Green is about recycled content and embodied energy when discussing insulation. It's not about "durability". Besides even on the durability scale, no studies show foam being durable. some suggest foam breaks down over time and loses R-value too. On the durability scale, cast iron bathtubs are "green".

Reading some of these insulation articles being circulated reveals builder/writers are far more harmful about providing deceitful information about insulation than any other sources besides a door to door salesman. Most often the R-value for cellulose is printed in these deceitful articles at some lower figure that the industry wide value of R-3.8 per inch. Loose blown fiberglass is much lower in R-value and shrivels in R-value by one-half in cold weather. Those are facts. If your list of "experts" want to have "opinions" about facts then who am I to stop them?

Mike

You state that you are able to have a 2600 SF roof sprayed with 8 inches. That is 20,800 board feet. That comes out to $0.27/board foot. I have never seen foam at that low price.

Personally I dont think we can build all of our homes and commercial buildings with spray foam as it is a petroleum product. That will put a great strain on the oil market when it heats up again. Typically we dont use oil to heat homes except in the northeast. OVerall heateing oil is a small part of oil use. Now to save oil you have created another use for it, doesnt make sense to me.

Bio based foams only have a small portion of soy oil so that is not a real alternative.

What are water pipes doing in exterior walls in new construction?

Are you aware that foam insulations only achieve an effective R value in the R24 range per a Fine Home Buildings publication. That is you can spray foam and what is assumed to be a R40 or higher thickness and that it will only preform at an R24 level. This does not seem like a good use of the resource.

If a home is built with vapor and water barriers on the outside that accomadate water getting behind exterior cladding and give the vapor or water an escape route then wetting of the insualtion will not be a problem - it will not get to that section of the wall. So I dont buy the wetting of the insulation argument.

I would also say that maybe you need to update your building practices if you need to use insualtions that let you know when you have built a leaky home.

I think as a whole the building and remodeling industry needs to learn from past building practices that lead to building failures. Now that we have the knowledge to understand what caused failure with (EFIS as an example) certain building practices and materials we can build more energy efficient buildings that are also durable. A few simple barriers would have prevented EFIS failures. Water intrusiion around windows can be prevented.

Many in the building sceince field have talked of the benefits of using foam board on the outside to block thermal bridging and to move the dew point away from building materials affected by moisture. Joe L and Joe S have reported how small details like double layers of crinkled house wraps can prevent vapor drive from wet bricks from reaching wall cavities. How foam boards can prevent thermal bridging and act as a rain screen. There are many more things that can be done.

As building scientist say the house is a system. We can build walls and roofs as systems. Using different materials in the wall to achieve the goals of energy efficiency and durability. As an example wall cavities can be filled will cellulose or fiberlass. The air barrier can be at the exterior of the sheeting. House wraps and foam boards can be extra layers of protection and insualtion. The claddings can be back ventalated to provide drying. Different systems can be used for different climates, etc.

The goals should be to make energy efficient buildings that are durable and get the maximum benefit from the materials. It doesn't mean that if 2 inches of foam is good 10 inches is better. That is a waste of oil.

I'd like to point out that "green" building is about conserving energy, not just in the construction, but more importantly, in the use of a building. There are two major factors of energy use... 1. R-Values (wall thickness, insulating materials, and frequency of thermal bridges) and 2. Convection!! I know this isn't the point of this article at all, but the debate went way too far without mention of air sealing (which you get with spray-foam products).

The energy savings from R-1 to R-20 is incredibly significant. However, the savings level off as you increase insulation beyond standard amounts.

Energy savings from air sealing does not have a leveling-point. The more you seal, the more you save, so long as you either provide mechanical ventilation to remove humidity and CO2 from the home, or don't seal the home to below 0.3 ACH (air changes per hour).

I'm a big fan of cellulose fiber, but in conjunction with sealing (either with 1G foam or simply caulking).

"Green building is about durability and performance more than about recycled content."

I disagree with Michael's very narrow understanding of what it means to be truly green.

Durability or longevity of a structure that is built with materials and methods which inflict a heavy burden on the earth's life-support systems is the antithesis of green. The greenest of shelters - including igloos, teepees, yurts and wigwams - are among the least durable. They return to the earth without residue, become compost for future growth, and are easily re-built with minimal environmental impact.

The reason that durability and longevity have become so important is because of the enormous ecological impact of our shelters, due in part to their excessive size and complexity. The proper definition of "durable" is a thing which outlives the earth's ability to recover from the impacts of its creation. A thing with very little impact does not have to live forever to be durable. But a thing with enormous impacts must stand for a very long time before replacement.

And "performance" is typically measured in the very narrow terms of energy consumption. But even that is heavily dependent on the size of the shelter and the number of mechanical gadgets it contains. And energy consumption almost always ignores the embodied energy and the embodied global warming contribution of our synthetic building materials. To suggest that it's OK to save petrochemical energy by consuming petrochemical plastics is analogous to waging war for the sake of peace. The means are at least as important as the ends, for the means create the ends.

To disregard what is probably the most environmentally benign and efficient insulation material on the market, borate-treated dense-pack cellulose because a major plumbing leak or a tree crashing through the roof or an ice dam (which is created by a poorly detailed roof with no ventilation, the standard with foam-insulated roofs), or a Katrina hurricane flood has created a moisture problem - is akin to blaming the victim.

In normal operation, with normal air and moisture penetration into the thermal envelope, there is no safer insulation than cellulose to prevent mold and decay problems, since its high hygroscopicity effectively redistributes moisture away from framing and sheathing and allows the insulation to safely store and release up to 30% of its weight in water without degradation. No other insulation material has such hygric benefits. Cellulose also helps moderate indoor relative humidity, much like thermal mass helps moderate temperature fluctuations.

Except for strawbales, cellulose is the most green of all insulation options currently on the market. Spray foam is anything but green and anyone who advocates such products should be drummed out of the green building movement.

And MerrickProperties has it backwards (which is typically the case with those who buy into the spray foam industry propaganda).

First, it may be true that "green" building (in quotes) is mostly about operating energy conservation. But true green building is about creating essential shelter within the laws of the natural world, which include: using only local, natural materials; using local labor and supporting the local economy; keeping size and complexity to a minimum; creating as little disruption to the site as possible; and placing the shelter within a pattern of human settlement that minimizes transportation needs and maximizes positive social interaction.

Second, there is a linear relationship between the R-value of an envelope and its energy efficiency (there are no fictional "diminishing returns"), but there is a top end to the value of air tightening since all homes require a minimum air exchange for livability and moisture and pollution control. Once a house is tightened to limit natural leakage to the ASHRAE 62.2 minimum standard for air exchange, there is little additional advantage to a tighter house (unless mechanical pressure imbalances or poor detailing create moisture problems).

Riversong, I agree with the first paragraph, when planning new construction, the holistic approach is key. However, the bigger fish to fry here is in renovations these days. (about 550,000 new homes built in the U.S. in 2009, compared to over 2,000,000 in 2005).

What you are wrong about is the "diminishing returns" and linear relationship. It is you that has it backwards. The heat loss/R-value relationship is not linear, there is a strong curve with drastically decreasing slope after R-20.

The convective heat loss/air change rate relationship IS linear. Air sealing beyond 0.3 ACH requires mechanical ventilation to ensure health safety, yes. But well worth the energy savings and added home comfort. HRVs are affordable when considering all the benefits.

Just for the record, Cellulose dense pack at 3.0 lbs/cu ft tests at R-3.6 per inch with a moisture sorption of <15% with an airflow resistance of 13 (lb/s ft)/(cu ft/s) By comparison, the type of micro-filament fiberglass I use is JM Spider fiberglass which can be dense packed behind a scrim typically at 2.2 lbs / cu ft dry at R-4.3 / in at with a moisture sorption less than 5% and an airflow resistance of 46 (lb/s ft)/(cu ft/s) so it has a higher air flow resistance than cellulose and can easily be installed to a higher R-value than cellulose. JM Spider can also can be sprayed-in similar to damp spray cellulose at a density of 1.8 lbs/cu ft at a moisture content of 10% or less at an R-3.6/inch, in our projects this is faster but very slightly more expensive than the scrim blown-in-batt method largely due to the fact that it requires more expensive equipment and a higher level of employee training and certification so we generally use the scrim and blown-in-batt dry system. In my market both of these Spider applications are about the same cost and both are equivalent in cost to dense pack cellulose but still less expensive than foams and with none of the flame retardant chemicals or other concerns associated with foam.

Anyone that thinks that the impact on global climate change should be a consideration in deciding what is "green", is very strongly encouraged to read the essential article on this at the green building advisor.

http://www.greenbuildingadvisor.com/blogs/dept/energy-solutions/avoiding-global-warming-impact-insulation

The lifetime global warming potential of HFC blown closed cell foam insulation is 450 times that of cellulose! In fact it can takes decades for the spray foam to save enough energy consumption, even in a cold climate, to make up for the damage done in making it.

Sorry to be so late with this comment, but I've only just read through all the comments on Mike Chandlers article.

The point I would like to make concurs with others made about sources of information, i.e. if you are going to make statements purporting to be facts, then please back those statements up with reliable sources, preferably from those backed up by proper research.

If the information is good, even from trade sources, it should be capable of being verified.

To give an example of fact versus fiction, some of the comments refer to fiberglass as a carcinogen, where nothing could be further from the truth according to the scientific evidence. The International Agency for Research on Cancer (IARC) (part of the World Health Organisation) changed its classification from Group 2B "possibly carcinogenic to humans" to Group 3 - "not classifiable as carcinogenic to humans" in November 2001. An irritant, yes, horrible to work with, yes, but not carcinogenic.

Facts please ladies and gentlemen, then we can have a civilised and informed debate.

We are building a new house and still deciding on what type of insulation to go with, hence my interest in this article and the comments that go with it--even though I'm reading nearly 2 years after they were written.

The facts and opinions shared are useful insomuch as they allow me to see the complexity of the issue. One thing I become wary of though is anyone who believes there is one way to be green. One only has to read the 30+ posts here to see that some people define green by the energy expended to produce it; others define it by the energy saved over using it into the future. Yet others point to durability in the face of unforeseen events (the water in the walls issue). And still others point out the implications of diverting food, eg.corn/soy-based products, from people who are hungry (even if in a roundabout way in that by using corn or soy-based foam we are encouraging farmers to produce something other than food for humans...). All these are valid points.

It seems to me that the sharing of information is important but that drifting over into an "I'm greener than you" discussion is counterproductive. There are too many variables for there to be ONE answer to what is the right insulation or the greenest insulation. Each project requires its own analysis and each owner is entitled to make a decision based on their own values, resources, and circumstances.

Now to my final comment that will probably incur great wrath! Am I the only woman who has commented here? In my experience, men tend toward a world view that is more black and white than women. Women see the nuances in things and are less likely to believe in the "silver bullet" theory or any particular statistic. (Although in your defense, there are several comments that DO seem to appreciate the nuances and DO seem to take a more measured approach.) Guys, lighten up! The fact that this discussion is even taking place is encouraging to me--it means people are taking the time to think through their actions and thoughtfully make the best decision for themselves. And those last two words are key to it all--"for themselves." My answer may not be exactly the same as yours, and vice-versa, but that doesn't mean we aren't still on the same side of the fence with respect to making a better world. Chill dudes!

I agree with the last post. What I did when I did my garage conversion was to put 1.5" - 2.0" of Closed Cell Spray Foam insulation on the walls. Now the garage had foundation walls so I built a new inside wall inside that foundation and staggered the studs. So I had a huge wall space and I ran all my electrical in the outside wall after the spray foam and then put in R19 in the walls for a total of about R26 or so and we took out the 2x6 Ceiling Joist!! Yes 2x6 and put in 2x10 and put in R30. There is an attic above this that I'm making a storage room that also has the spray foam in it and then I have R13 on top so maybe not the best in this space but the heated space has all it needs.

I had challenged MerrickProperties when he made two incorrect claims:

"The energy savings from R-1 to R-20 is incredibly significant. However, the savings level off as you increase insulation beyond standard amounts."

"Energy savings from air sealing does not have a leveling-point."

And then he returned by simply repeating the error (which is generally found in the advertising claims of the foam insulation industry which often tries to sell less than code minimum R-values as acceptable). He also ignored that "standard amounts" according to the current International Residential Code has been climbing, with R-38 to 49 ceilings required in the majority of the United States (including for renovation work in some areas).

I teach Hygro-Thermal Engineering and this issue needs to be better understood.

MerrickProperties re-stated: "The heat loss/R-value relationship is not linear, there is a strong curve with drastically decreasing slope after R-20."

R-value is mathematically the inverse of heat flow. Double the R-value of an envelope and the heat loss through that envelope is cut in half. That's a perfectly linear relationship.

What is also true is that, when the heat loss has been halved initially, halving it again reduces it by only one-quarter of the initial amount but by half of the new baseline amount. And energy savings, which is a linear relationship, may not be the same as lifetime dollar savings when payback on investment is considered.

Where there is, however, a point of strongly diminishing returns on insulation beyond about R-20 is with closed-cell spray foam or XPS foam board, both of which at present use blowing agents that are much more powerful greenhouse gasses than CO2. The lifetime global warming savings of such foams becomes negative after a few inches of application, which means you may not be able to achieve code minimums without doing planetary damage.

As for the alleged "no diminishing returns" on air sealing, most case studies dispute this. It's relatively easy to air seal new construction to the 2-3 ACH50 level (that meets or exceeds all current US codes and energy programs) without additional expense beyond being attentive to details. Decreasing it beyond that requires both a level of attention and a dollar cost that are either nearly impossible in the trades or not justifiable in the market. And there is little advantage in terms of building durability, indoor air quality or energy savings since ASHRAE sets a minimum required mechanical ventilation rate which assumes a natural leakage rate of 0.15 ACHnat, which is the equivalent of about 3 ACH50.

Riversong,

Try this wording and please (before you respond) check your facts with a credible source.

The savings seen from increasing from R-1 to R-2 is greater than the savings seen from increasing from R-30 to R-31.