We argue whether the durability of vinyl siding makes it a green choice, and there are quite a few people out there who are impressed by a factory-applied finish that promises us 25 years before the next paint job. But chemical bonding of the synthetic sort is not the only path to extra-long-lasting siding.

I was reminded of this in a recent conversation with author Nan Chase. We were talking about Fine Homebuilding’s latest special issue, Green@Home, which Nan had just picked up off the newsstand. In my mind, much of the point of the issue was to demonstrate how “normal” sustainable, energy-efficient homes really were. That they didn’t have to be weird trapezoidal solar-powered fantasies on one hand, or mud huts on the other, but could be as ordinary-looking as your neighbor’s clapboard and still respect the earth’s resources.

I’m sure that approach helped bring “green” building home to more (perhaps less adventurous) people, but Nan convinced me that we missed out on some of the more creative applications of the green mindset.

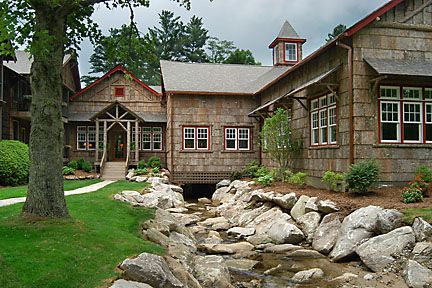

Nan’s home in Asheville, NC, is a bark house—that is, it’s shingled with flattened, kiln-dried-but-otherwise-untreated poplar bark. Harvested off trees felled for other purposes, bark certainly seems like pretty sustainable siding. It’s a local product, adds to a home’s insulation and reportedly lasts up to 80 years without the benefit of paint, stain or chemical protection.

Nan learned all this while writing a book with Chris McCurry, co-owner of Highland Craftsmen, Inc. a manufacturer of bark shingles and other bark house products. Halfway through, she and her husband decided that they wouldn’t cover their new house with anything else.

For sure, it’s a look you (not to mention the neighbors) have to get used to. But we’ve been able to accept structures wrapped in brick, metal and even plastic—so bark may not be as much of a leap as we think. After all, it is the siding of choice for forests the world over. And tell me—how could 400 billion trees be wrong?

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Musings of an Energy Nerd: Toward an Energy-Efficient Home

All New Kitchen Ideas that Work

A House Needs to Breathe...Or Does It?: An Introduction to Building Science

View Comments

Oh, yea ... all in favor of mushrooms growing on the house, rodents burrowing, insects nesting, and termites having an orgasm at just the thought ... let's hear it for bark!

Be fun to paint later on, too. The term 'sponge' comes to mind ... and I'd hate to try to patch or caulk it.

Finally ... as so well being demonstrated this very moment from Southern California to British Columbia ... let's make it even easier for the house to catch fire!

Finally, do you think the 'nature nazis' that obstruct logging will agree to harvesting bark? Not likely.

We are using it on a project right now and the product is very easy to work with and looks great. You need to strap it back into the pallet presses every night to keep it from curling and it nails 3"oc w/ 8d ring-shank gun nails but overall a very good product, somewhat more expensive than red label cedar shingles but we are finding it to be a dramatic way to give a rustic flair to a lakeside retreat we're building.

The tree huggers love it due to the fact that it is made from sustainably harvested, FSC certified, poplar logs that are headed to the furniture industry and if the bark were not harvested from the logs it would be shredded at the sawmill for mulch or fuel. It employs folks who need work in the mountains of North Carolina and keeps them on their land.

Due to the fact that it is a rustic material to begin with it is easy to patch and repair, minor dings and blemishes disappear into the overall texture of the product. We do have wide roof overhangs on our buildings and we apply it over a double wrap of tarpaper over taped tyvek wrinkle wrap. so the "sponge" issue is no problem. I can't imagine ever painting or caulking this stuff, that would be like painting drystack field stone, why would you?

If the product works, I would definatly consider it on my future home. I would definatly wait for some "long term, real world" regional testing before jumping.

That fact that it is "green" (a term I think is starting have bad conotations) would be only be a bonus. From a effeciency point of view, anytime we can do anything with minimal waste, the better for cost and everything.

I like the look, however it should be a lower priced option than other alternatives in time.

Hi from Northern Contry, Canada. I'd like that one of you comment the post submitted by renosteinke! also, I'm wondering about how that material, once cut into small shingles would withstand the weather we have here in the Québec, weather that can vary from -40c to + 40c, high winds, snow, freezing rain etc., etc.

Of course trees around here don't get undressed with weaather but once cut into shingles??? We use Cedar, well (thuya occidentalis) for roofing especially in maritime provinces) wich has it's share of bad weather but no -40c.

It's a very interesting alternative to vinyl which I personnaly hate and never use but...

Great job Guys!

Jean-Pierre Maher, in the contry, Canada

Let's get one thing perfectly clear, vinyl siding has never been, is not, and never will be environmentally friendly or green. The chemicals that leach or off-gas from of all vinyl products are constantly given credit for more environmental concerns and health effects.

It's amazing how we have banned lead paint products and get all up in arms when our pet food is tainted with melamine but when it comes to the health of our home and the effect it has on our family's health we are still blinded.

The only people getting any benefit out of vinyl siding are the chemical companies, the siding manufacturers and distributors. This is because each of us feels we have earned the right to live in over sized "luxury: homes. The process of creating a home in itself is unsustainable, therefore we have to use unsustainable practices to create such housing stock in the first place.

To counter my rant, what's wrong with building a house that is more suitable to the materials that occur locally. There's nothing more sustainable than using local materials, and reusing these materials when the original structure is dismantled.

There is also a Japanese technique called shou-sugi-ban. Japanese cedar (cypress) is charred and then sealed prior to installation as siding. I guess we have to decide if burning cedar is green as well.

I do like the article and that it highlights alternatives. And there are alternatives out there. The problem is can these alternatives overcome the competition from mass produced and distributed products?

I'm with renosteinke. My first thought on reading this post was that the pileated woodpeckers would be down to the sheathing in about five minutes just to see who was living in the walls, and then the mushrooms, lichens, mosses and creepy-crawlies would finish the job. Bark rots, fast. What's to stop it, just because it's on a house?

The fire hazard is also a very legitimate point in burn zones.

Granted, I have not researched this product so maybe I'm missing something, but I have to say that logic fails here. Vinyl is not the alternative, of course, but bark seems like a pretty silly answer to the green effort.

When I looked into bark siding recently the cost was outrageous-substantially more than clear cedar. I am surprised no one has mentioned this. If you want a durable green siding product, it is hard to beat locally sawn board and batten-in most of North America it is possible to get low grade white oak, black locust or other weather resistant wood for a couple bucks a square foot-or less.

Big difference in the off gassing of vinyl products between UPVC and PVC products.

More off gassing out of a flexible shower curtain than there is in most houses that are covered in vinyl siding.

Don't get me wrong, I am not a big fan of vinyl products, however, they are sometimes "greener" than their touted green replacements.

Take a look at the article below.

http://www.edcmag.com/Articles/Sustainable_Flooring/ae50bb13fb697010VgnVCM100000f932a8c0____

I would like to seem some projected lifespan analysis of a product like this.

Lets be honest with ourselves people, are cedar shingles on the side of a building really "green" when they require regular chemical preservative applications to maintain their appearance and prolong their lifespan.

If vinyl recycling were in full swing, this would be a non-issue. Unfortunately, recycled vinyl is more expensive than new vinyl.

Before you install something burnable on the side of your or a customer's house, perhaps you should go look at http://www.firewise.org ... There's a reason people living in the deep woods should consider a cement fiber planking.

OK first off I have never seen this product nor installed it and have no stock in promoting it.

But I do spend a lot of time in the woods and working with wood so I do know a few things about bark. logs and how they rot and I have helped in forrest fires areas and I have heated with wood for over 30 years so I know a little about how trees burn.

To those of you that think bark rots fast you are simply misguided if you look at logs rotting the inside wood is the first to rot in fact the bark can be intact over a completely rotted log. Also the bark is the trees natural defense against insects they get through it yes but it is the wood on the inside they are after not the bark.

And if you need proof of the water resistants of bark take a look at a birch bark canoe if you know anything about other wood boats you know that the wood must be treated or coated with some type of water sealant but except for the seems a birch bark canoe needs no such protection to make it repel water so those that think of bark as a sponge you also are misguided since if that was the case a birch bark canoe would not float for long.

Also Cork you know the stuff we seal wine bottles with is Bark. It does not absorb water nor does it rot if it did it would not be much good at sealing a wine bottle stored in a damp wine cellar for years.

As for Fire well not all trees and bark are the same but on most trees the bark is actually it's protection against fire is rests burning the outside of the bark will char but often will not catch fire completely protecting the tree from the heat. Now it is still wood so once the fire is hot enough it will burn.

Just put a split log with the bark still on it in a fire you will find the bark may char but the unprotected wood will catch flame faster.

Now Many get the idea that barks burn easy because of it's use as kindling and think of birch bark used as kindling and assume all barks burn easy but it is the fact that birch bark is thin as paper and loaded with oils that it catches on fire easy. Bark is used for kindling because it can be easily shredded into thin pieces and when it burns it actually burns slower and hotter then equally thin sheds of wood.

So it catches quickly because it is shredded into thin pieces but does not burn so fast that it burns up before the larger piece of wood can get hot enough to burn. But solid bark in thick pieces actually takes higher temps to catch flame then other parts of a tree. If you took equally thin pieces of dry wood it would burn up before it got hot enough to catch the larger pieces of wood which is what the job of kindling is not to burn itself but to catch other larger wood on fire. All parts of a tree will burn but out of all the parts of a tree it is the bark that usually takes the highest temps before burning.

So get past your misconceptions about bark and take a closer look at a good product. If local to your area it can be a very green alternative to other siding. Of course being green should be about picking local materials first since if it takes a ton of fuel to ship a product to you that counters any green benefits.

Never use a cement fiber planking where you have high humidity or snow that stays against the siding for long periods of time. I have had and currently have houses with cement fiber siding and humidity will cause the siding to crumble like cardboard. Moisture is impossible to keep out in the humid areas of the country. I have seen this siding fall off houses from Maryland to Mississippi. It works good in the dry western states. If fire worries you go with a concrete house.

We don't have the fire problems as bad in the east so wood in the forest is not as bad. In my area of WV we have not had a forest fire in the past 60 years that I recall. Our fires start mainly from wood stoves when the weather starts to get cold. We still heat with wood in these hills.

I see cost as the big problem for us. A $40,000 house is out of the reach of 95% of our residents.

The jury is still out on the longterm value of bark siding. It does seem problematic relative to mositure and more importantly insects. We carve bark and understand how fragile it really is.

ALSO - we have a cement fiber siding on our home. It is in it's 11th year and looks as good today as the day it was installed. We have a large, cape cod with attached garage and a walk out basement. 7 gallons of paint. We live in Northern Iowa where the snow gets painfully deep. We haven't had any siding swell and crumble off our house.

We also didn't experience any hail damage this year. Several home finished in vinyl looked like they went through a shredder, I wonder how bark siding would have stood up to hail?

There are very old structures on the Appalachain Trail constructed of Chestnut bark siding and still durable. I checked out this product pretty carefully and had two concerns. One was the rustic look and the second was price. One vendor advised a full overlap of the siding requiring 200 feet to cover 100 feet. At that coverage and the cost of materials it became very expensive. Like many "green" products, it costs a lot of green. Otherwise, it appears to be as good or better than any other wood siding product. I suggest that you check it out if you like the rustic appearance. I ended up choosing pre-stained cypress, also from North Carolina and much more reasonably priced but much more of a maintenance burden down the road. But it is wood, not cement or plastic. In town I would use brick or stucco and not endure the hassle of wood.

siefel may be confusing fiberboard with cement board. Fiberboard (also known as hardboard) is quite susceptible to water damage. Cement board is pretty much at the other end of the spectrum. That is very resistant to water damage. Cement board also holds paint for a long time due to it's dimensional stability. I have, however, heard that the production of Portland cement uses a lot of energy.

There’s been a lot of chatter about bark shingles and apparently a lot of questions. I am the co-owner of Highland Craftsmen Inc, the original poplar bark shingle manufacturing company. Our company photos are used in the article (HC). I’ll try to briefly address some of the questions. I’ve placed responses in alphabetical order for readability. The answers provided are reflective of Bark House® brand shingle manufacturing practices.

Bugs and Pests: HC kiln-dries and heat sterilizes all our Bark House brand shingles. Our process is third party certified. This is important because all living organisms are rendered inert in this process. That includes any attached bug larvae, mold spores, moss and lichens, etc. With the cambium layer dried, there is no nutritional value for bugs or wood peckers. The bark itself is chemically bug resistant by Mother Nature’s design. Bark is the first line of defense for the tree against bugs.

Care and Pre-care: You will receive a professional pre-care, installation and care guide with every order. There is no need to re-band the shingles every night if they are kept out of the weather and installed promptly. There is no issue with curl, given that the pallet is kept in the dry like wood flooring would be. It is when the pallet remains un-banded over long periods that curl becomes an issue.

Climates and Locations: Bark shingles have been used in nearly every US state and in other countries. They have lasted in 4-season climates for over 80 years. We field test and observe their longevity from arid high elevation locations to wet and stormy coastal areas. We will be happy to discuss application in your region.

Cost: The initial cost is at the top of wood cladding products. However, you do not have to paint, stain or seal the product. Add these and the labor for their application and the initial cost variance is decreased. The life-cycle cost of the product is where the savings really are. Maintenance free products are attractive related to cost benefits and the free time and re-sale value they generate.

Durability: We monitor homes with poplar bark shingles still performing that are over 80 years old. Bark is the natural protector of the tree and is rugged by design.

Fire: HC performed fire testing on our product through an independent laboratory. Bark House brand shingles have a class B fire rating. Most wood products are class C. That means bark shingles are more fire resistant than other natural wood products. A Class A rating can be achieved through chemically fire treating.

History: Bark shingles have a remarkable history. Visit http://barkshingle.org/.

Lap: The historic installation of bark shingles was to do a full shingle lap. That is because the houses were not insulated and air flowed from inside to outside spaces. When the bark shrunk (and it would without kiln drying), the full lap maintained the home’s integrity. Material availability, air-tight construction, cost and the need to minimize waste meant that HC had to reinvent the way bark shingles are manufactured and installed. The result is that we recommend a minimum two inch lap, not a full shingle lap.

Maintenance Free: In most all circumstances, paint, stain, sealers and especially caulk are never used.

Quality Control HC has an exclusive 5 point quality control program that ensures your bark shingles meet our exacting specifications every time.

Sustainability: HC is proud to have achieved our FSC. PEFC and SFI CoC certifications. Please visit this page of our website to learn more about how bark shingles are sustainable: http://www.barkhouse.com/index.php/products/bark_siding/bark_shingles_a_green_product/

While the siding was more expensive than the red label shingles we usually use, it certainly did go up a whole lot faster.

We scattered pallets of the shingles around the house wherever we had work stations to minimize hauling so we covered and banded it every night. It may not have been necessary but it was easy to to.

Everybody loves the look (especially the home-owners.) The stone mason landscape designer came through this week and it was "oh yeah, this is going to be fun." from both of them. the crew are real happy to be working on this unique project.

My grandfather covered the family cabin with cedar bark in the 1920's. This bark wasn't kiln dried or treated in any way. The bark still looks great, has never had any bugs, woodpeckers, mushroom, mold, rodents or any of the other horrors I'm reading the the prior posts. The house is in a shady location and has snow piled up against part of the bark for several months every winter and looks great to this day.

Also, we have cement stucco board our our house. It hasn't been painted in 10 years and looks like it was just done. It has had snow up against it for 10 winters and no crumbling or any of the other damage mentioned. I will go with either bark or cement board on my next house.