Make Old Walls Smooth and Sound

Cracks, peeling paint, and bad patches disappear with a wide roll of adhesive mesh and two thin coats of joint compound.

Synopsis: It can be tricky to repair old plaster walls properly, but finish carpenter Tim Leahy has a technique that works well for restoring cracked, chipped plaster walls to their former smooth, sound glory. His process also works on drywall. Leahy starts by making the wall clean, dry, and dull, and performing any necessary repairs, such as reattaching plaster that had separated from the lath or filling large cracks. Next, Leahy covers the walls with self-adhesive fiberglass mesh, taking care to overlap inside and outside corners. After the mesh is on the walls, Leahy applies two thin coats of joint compound. When the walls are dry and smooth, they are ready for a coat of primer, then two coats of paint. This article includes a sidebar listing the tools and materials for this type of project, including plaster washers and screws, joint compound, a 5-in. taping knife, and adhesive mesh.

The historic mansions that my crew and I work on in Newport, R.I., are sometimes bankrolled by folks who can afford to restore them to their original glory. This means that we strip paint off hundreds of feet of woodwork and repair a lot of plaster walls. Last winter, we were hired to paint the interior of the Eisenhower House at Fort Adams State Park. Because the house is state-owned, the budget was tight. Lucky for us, the woodwork was in great condition, but the walls needed serious attention. Hairline cracks, poorly made patches, and large sections of peeling paint were evident in several rooms that needed to be painted. We made them new again with a technique I’ve used on many preservation projects.

After scraping loose paint and securing crumbling plaster, my crew and I covered the walls with wide fiberglass mesh, then applied two thin coats of joint compound. At about 35¢ per sq. ft. plus minimal labor, the results can’t be beat. The walls are clean and smooth, and they won’t crack again. Also, any potential lead hazards are now safely contained. While we typically use this approach on plaster walls, it works on drywall as well. Before we touched the fiberglass mesh or opened a bucket of mud, though, we inspected the walls to make sure they were sound.

|

|

|

Cracks, peeling paint, and bad patches disappear with a wide roll of adhesive mesh and two thin coats of joint compound.

Get it clean, dry, and dull

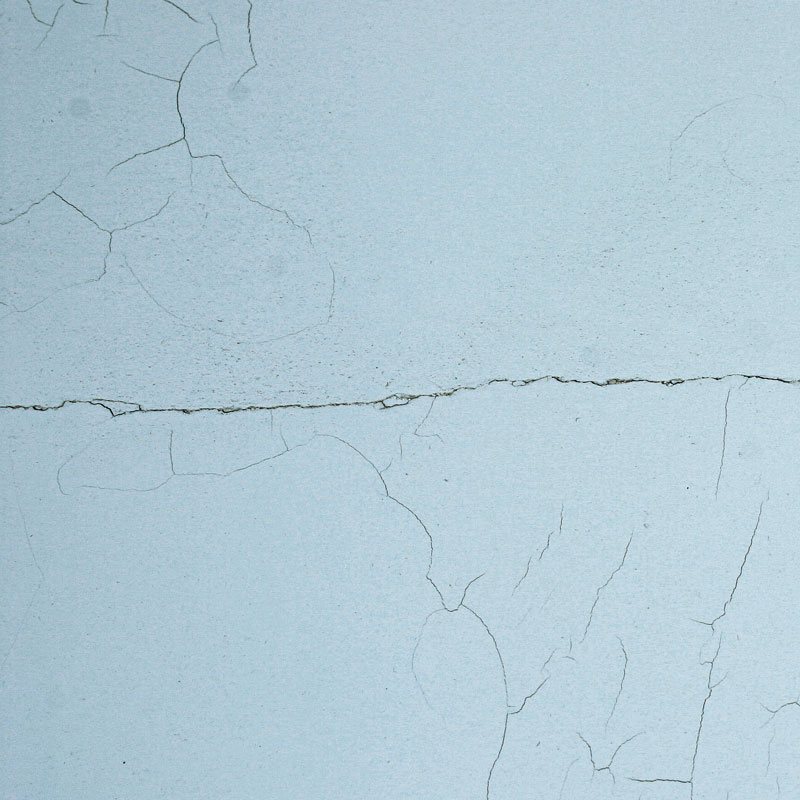

As time goes by, plaster succumbs to substrate movement, moisture, alterations, and repairs. On the surface, mildew, chalking, paint failure, and cracks were all easily visible. Before applying the mesh, we scraped and/or sanded any loose or flaking paint and leveled old patches and imperfections.

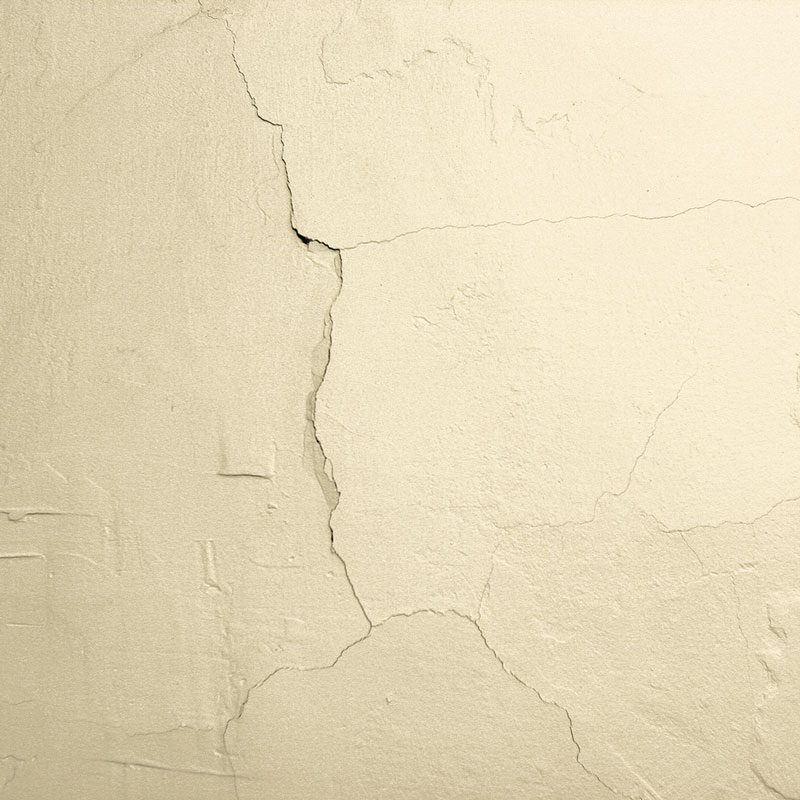

Deep cracks indicated structural movement, so I brought in one of our carpenters to assess the problem. He determined the cause and that it had been addressed long before we’d gotten there. At that point, my crew and I inspected the plaster more carefully, then stabilized loose areas.

We looked for paint that flaked off easily and for bulges in the surface, which indicate that the plaster keys had broken, releasing plaster from lath. When necessary, we used plaster washers and screws to tighten the wall back to the lath.

Some of the plaster flaked off in chunks. In these instances, we chipped away at the loose plaster until we reached an area where the keys were clearly intact. We then patched holes smaller than 8 in. dia. with setting-type compound, such as Durabond 45. Although we didn’t need to patch anything larger than 8 in., I typically patch large areas with drywall. Setting compound can slump when applied over big areas, requiring multiple coats and sanding. It’s best to attach the drywall directly to lath; cutting away lath undermines its strength around sound plaster keys.

We scraped away all flaking paint until we reached a place where it still adhered soundly to the wall. Because we were working in a home that predates the 1970s, we did all this with lead safety in mind. I suggest reading “Lead-Paint Safety, at Home and on the Job” (FHB #150 and online at FineHomebuilding.com) and visiting the EPA’s Web site (www.epa.gov/oppt/lead) for guidance.

Once the walls were patched and sound, we vacuumed them to remove dust that would interfere with the adhesive on the mesh. We used trisodium phosphate (TSP) and a damp rag to clean areas that were chalky or had greasy residue.

Self-adhesive mesh adds strength

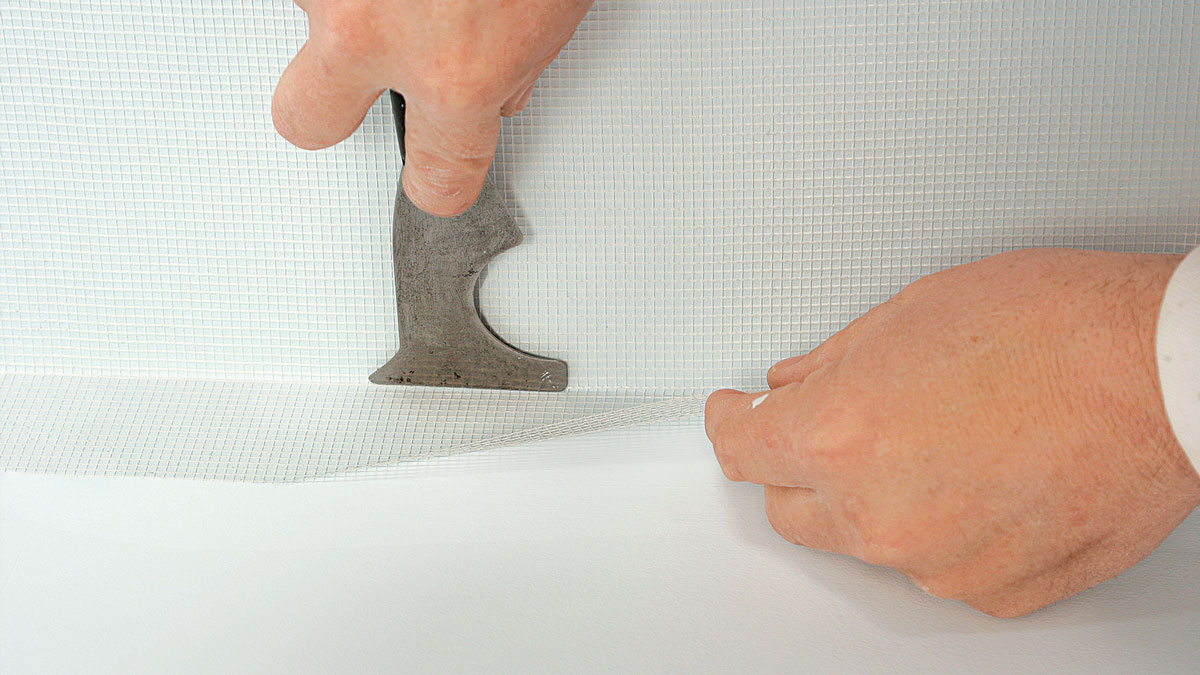

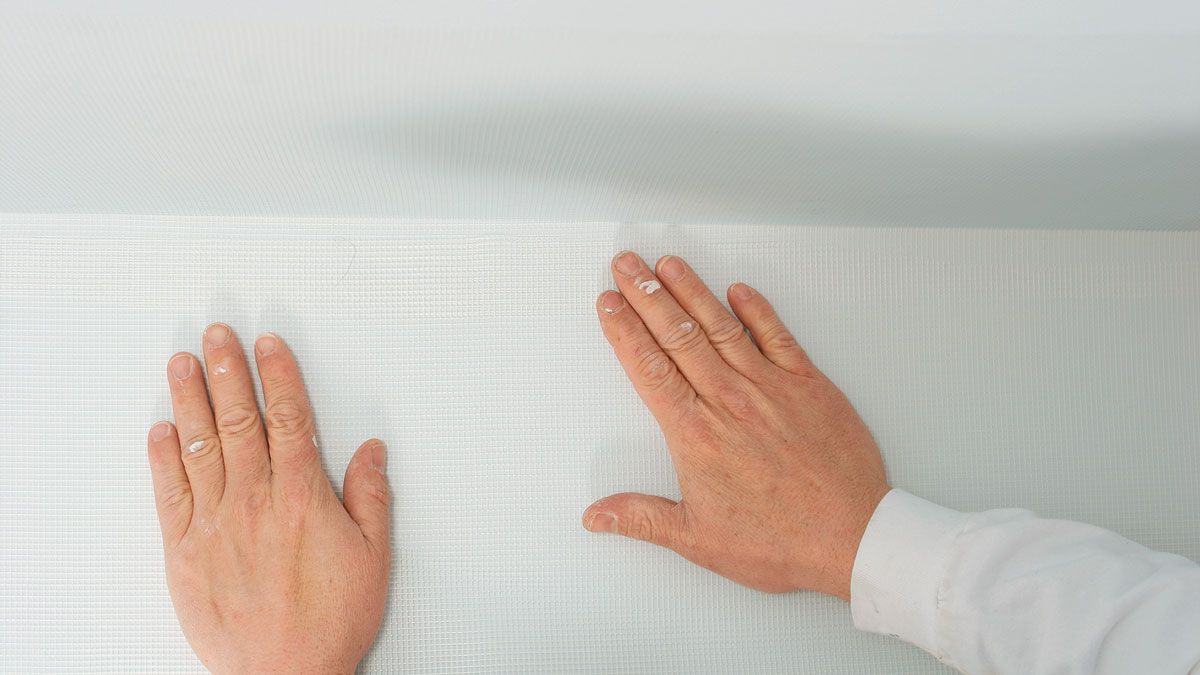

The fiberglass mesh we use comes in 3-ft.-wide by 75-ft.- or 150-ft.-long rolls. We apply it in vertical strips, overlapping each seam 1 in. to 2 in. Unrolling the fiberglass is easier if you approach it as a two-person job.

We started in one corner of the room and worked from the ceiling down to the baseboard. I like to run the mesh past inside and around outside corners by about an inch, then overlap the next section. Doing so makes for a stronger joint that is unlikely to crack. As with wallpaper, we let the mesh run long by about an inch at the ceiling and at the baseboard, then trimmed it later.

The key to rolling the mesh is to have about a foot well-adhered before trying to unroll large sections. This takes advantage of the adhesive’s strength. Using an open palm, we smooth the fiberglass over the wall, working from the middle out to the edges. Every once in a while, it is necessary to peel a bit back and reposition it to keep it smooth and wrinkle-free. I find it easy to trim the mesh with a utility knife and a taping knife or wallpaper edging tool.

All-purpose compound does the trick

For the skim coat, we used USG’s all-purpose joint compound because it is premixed and sands easily. To make the compound easier to apply, I mix it with a paddle mixer.

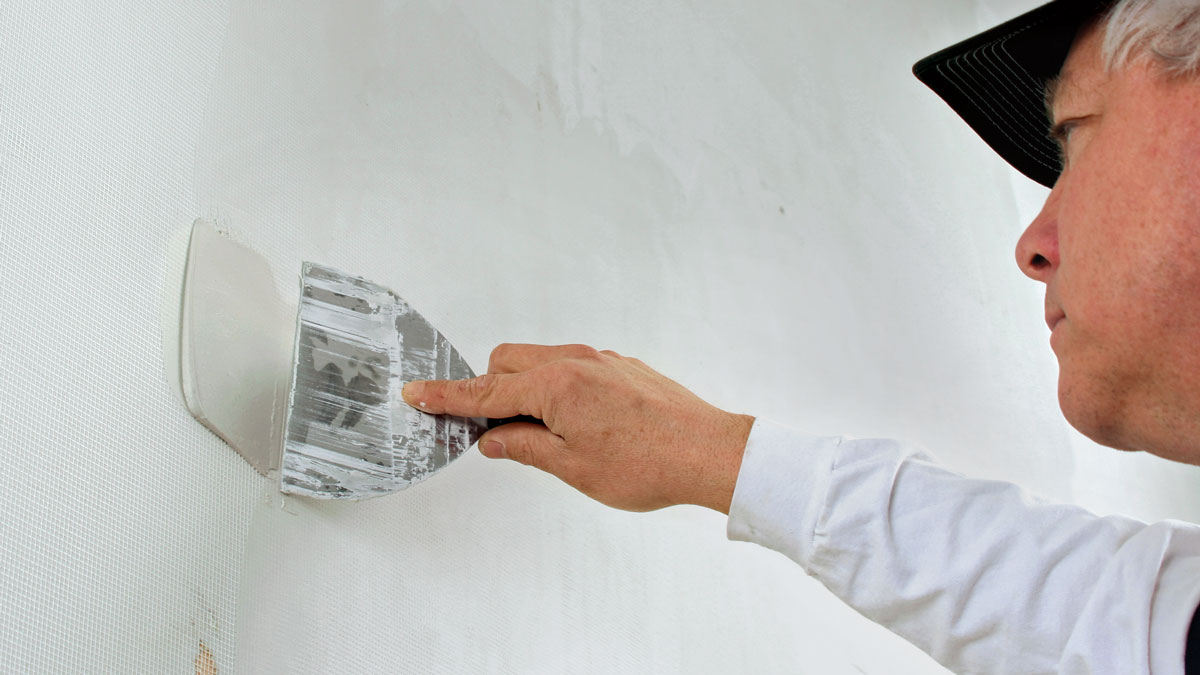

Although a wide taping knife might seem like the most logical tool for this job, it isn’t. Wide taping knives have a bend in the center to help float taped joints. For this application, a perfectly flat knife is key. I’ve found that a 5-in. knife is a good choice. We applied the mud in a two-stroke fashion using a 5-in. knife. The first coat should be only as thick as the mesh itself, so with the first stroke, we applied the mud to the wall. Then we scraped it off with the second. We also made sure to work the knife in the proper direction of any overlapped seams so that we didn’t lift the mesh.

After allowing the first coat to dry overnight, we inspected the surface. We knocked off small nibs or ridges with a taping knife or with 120-grit sandpaper. We trimmed bubbles or wrinkles flush with a razor knife and filled them with compound.

We then applied another coat in the same fashion, again removing the excess compound to leave a tight, neat surface. Once the second coat was dry, we used a fine sanding sponge to smooth out minor imperfections. I didn’t worry about areas where the mesh was slightly visible because the primer and paint would cover them. You also can use joint compound to spot-coat areas where the mesh sits proud of both coats.

Once the walls were well vacuumed, we applied an acrylic primer, then two coats of Benjamin Moore Regal wall paint. The wall profile and slight irregularities were not changed in this project, but the surface is as it used to be: even and smooth.

Cover the walls with mesh

Peel, stick, and roll. Start each section by peeling several inches away from the roll, then pressing it against the wall. Let an inch or so run onto the ceiling. Keep the roll horizontal as it’s unrolled to ensure that it stays in a straight line down the wall.

Overlap inside and outside corners

Apply two thin coats of compounds

Work the room

Before you prime, sand the highs, and fill the lows

Use wide mesh and a narrow knife

Although covering walls with adhesive mesh and applying two thin coats of drywall compound take a little time, the process requires minimal sanding and costs only about 35¢ per sq. ft.

|

Reinforce plaster that has pulled away from lath with 1-5/8-in. drywall screws and plaster washers (a 120-count container costs $20; www.charlesstsupply.com). |

Coat the mesh with two thin layers of all-purpose joint compound. Allow each layer to dry 24 hours before recoating and/or priming. A 5-gal. bucket of mud costs about $11 at most home centers. |

|

Use a knife this size to apply the compound to a wall or ceiling. The work goes quickly. Wider knives curve in the center, so it’s difficult to get a smooth, even layer. |

Apply 36-in.-wide adhesive fiberglass mesh over the entire wall to create a strong, unified substrate for the skim coats. The FibaTape SuperCrackstop (www.fibatape.com) used here costs about $35 for a 75-ft. roll. |

Tim Leahy is a finish foreman for Kirby Perkins Construction in Newport, R.I. Photos by Chris Ermides, except where noted.

From Fine Homebuilding #208

View Comments

If you're going to go to the trouble of knocking out the plaster to the lathe why not use gypsum plaster and plaster for a scratch and brown coat and finish it off with lime plaster or plaster of paris. You would also do well to add a bonding agent to the lathe and some fiberglass to the gypsum plaster when you mix it.

I'd like to see the finish after the plaster washers are applied but I think there better solutions these days