Nobody is saying that a tape measure and pencil are obsolete, but the SawGear coming to market certainly makes them appear about as high tech as the bunny ears on your Aunt Gertrudes television set. While I haven’t gotten my hands on one yet, I thought I’d chime in with a few initial thoughts.

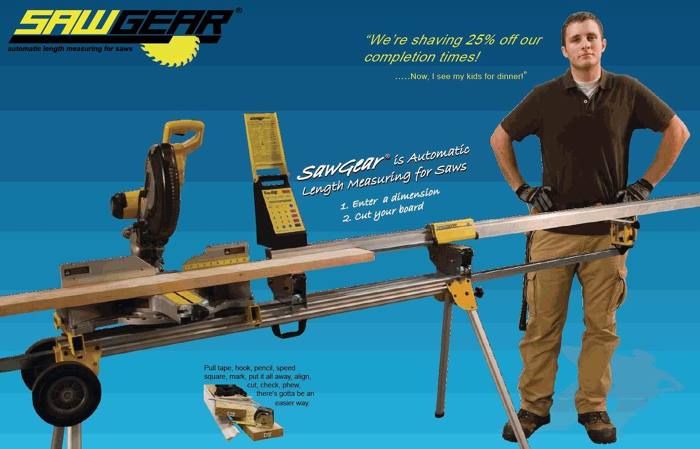

This tool has an electronic stop that slides down an armature at the push of the keypad, giving you perfect lenght cuts in everything from 2xs to trimwork. The process is pretty straightforward, you attach this armature to your miter saw/stand, calibrate it to the blade, and you’re good to go.

Once you know the measurement you want to cut, you just punch it into the keypad on theSawGear armature (in either fraction or decimel form), press the “start” button, and the stop slides down the track to the exact distance from the sawblade.

When cutting angles, you punch in your outside measurement, swing the miter saw to the appropriate angle, and you’re good to go. In fact, you can cut miters just by entering the inside length of the piece (the head casing on a door, for instance) enter the width of the trim stock, and the stop will slide to the appropriate distance to give you a perfect long point measurement for the molding.

The downside, and it’s a BIG one, is the price. Get ready to sell your wife’s fine china, because for an armature that has an 8 ft. capacity, you need to shell out about $2,200. If you want to be able to cut 12-footers, the pricetag is $2,500.

But then you’ve got another problem…where to store this thing? The armature that can handle 12 footers is over 13′ long. That means you’ve got two choices, a really big trailer, or a white-knuckled ride on the roof rack of your pickup or van.

My gut tells me that unless you have trim jobs where you are installing miles (literally) of trim, this tool would take a long, long time to pay for itself.

Am I just being close-minded?

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Affordable IR Camera

Handy Heat Gun

Reliable Crimp Connectors

View Comments

It looks like it folds/slides down and has wheels, no? It's not really always 13 feet long and seems to be portable.

Good for a permanent setup.

Ok, it all sounds good, but they must be joking about the price. If the darn thing is made in China just like anything else around here, then why the heck they priced it out of the market. Even a contractor won't shell out that much money on something like that yet alone a hobbyist. then they wonder why they don't have that many people picking up this kind of hobby "woodworking". I wonder why?!

Home Depot has the 12 ft version for $2995.00. If it saved 1 second from every cut that a $20/ hr guy makes, it would take roughly 54,000 cuts to break even. (Our case and base wunderkind would probably loose time punching the keyboard.)

And according to the video of the worker unloading the thing from the truck it does look like it's a single piece.

Yeah, you might say I'm a little skeptical. I won't go on about machines making us all lazy....

I like the concept. Having worked around CNC stuff before, and making many repetitive cuts trimming hundreds of homes this idea had crossed my mind. But.... would it save time over what we do now on our crew? I doubt it..Not with having to enter manually with a keypad and wait for the stop to move. Then there is the issue of transport. We are looking at ways to work more efficiently with less tools to size down our truck and trailer to save fuel. So something like this would have to really be a time saver to earn a ride to the job site. I think a setup with a plain ruler or a digital readout that would read like a tape and a solid stop on a ball bearing slide that you move manually would be faster and cheaper. If they came out with a 16' version that folded down to 8' and would take measurements by voice command I would be much more interested.