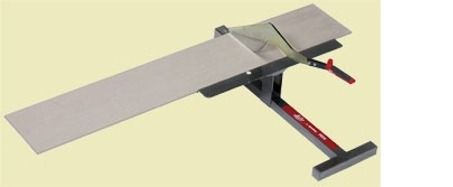

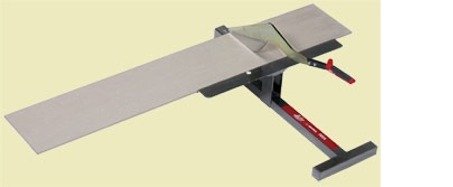

Malco brings us another option for cutting fiber cement; the FCC4 is a simple manual shear that crosscuts standard 5/16 in. thick planks up to 8 ¼ in. wide. Leverage alone drives the semicircular blade through one panel at a time with a pretty crisp cut and no break-out the backside. Cuts are dust-free like you get with nibbling shears but nice and straight.

The size and design of the FCC4 make it best suited for a cut station arrangement. The base is 27 in. deep and needs full support to keep the pivot end from lifting up during a cut. The table extends 11 inches to each side of the cutter; not wide enough to hold up long pieces of siding so you need to craft a support system. I ripped scrap 2×6 blocks down to match the 5 ¼ in. deck height and spaced them about 2 ft. apart along a plank table for panels to rest on. You could easily attach a stop along the supports but I found the integral stop adequate to align panel edges to.

The cutter is light and tends to slide around on a workbench. To keep mine in place, I drilled holes in the ends of the 9 in. long front and rear base support bars and screwed it to the table.

The ¼ in. thick cutter bar flexes when you force it left or right. Keep this in mind when making cuts and direct your force straight down for square cuts. If you do need a slightly off-square cut you can eek out 1/16th in. by flexing the bar. And unlike nibbler shears where you cut with the backside facing upwards, with the FCC4 the planks face up.

List Price 209.99

Street Price $179.95

http://www.malcoproducts.com/products/sidingfiber/fcc4.asp

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Handy Heat Gun

Affordable IR Camera

Reliable Crimp Connectors

View Comments

Skimpy handle adds new meaning to "hand shear"

I tried one of those at BuildEx last year. It does a fine job and doesn't create any dust, however the handle needed improvement. Its way too narrow. I get the impression after a day on that shear you'd be curious about RSI symptoms.

Did you find it painful to use or have they improved the handle?

John

You're right - The handle is narrow and does not have a padded grip. I wear a good pair of carpenter's gloves when I use it so I don't notice any fatigue after cutting on and off for a day. The cut guy on a production crew would probably have trouble. One suggestion I'd make is to get some good pipe insulation like Armorflex to wrap the handle as a cushion.

I've never used the product, but could you attach a piece of pipe on the end of the handle to create a T? Might this help with fatigue?

A piece of pipe to extend the handle would be a good idea. It doesn't necessarily have to be oriented opposite the handle (ie 'T'). Just slipping it over the end should work.