To provide a positive mechanical bond for stucco and stone veneer, builders are required to install lath over felt paper or housewrap. But if you have ever worked with conventional galvanized expanded-metal lath, you know it’s anything but a pleasure. Metal lath is sold only in large sheets that are sharp, are prone to rusting, and must be fastened through housewrap or felt paper in such a way that water migration can occur. To me, the future of lath is in products like SpiderLath.

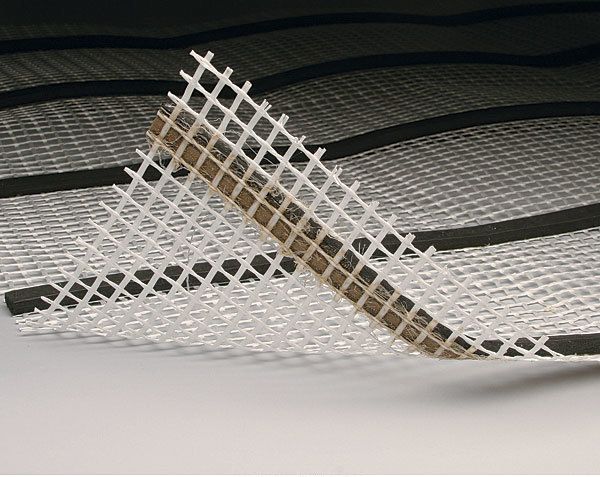

Sold in 4-ft. by 75-ft. rolls that weigh only 25 lb. and have no sharp edges, SpiderLath will change the way you work. Made from alkaline-resistant fiberglass, SpiderLath is actually stronger than expanded-metal lath, but it cuts with a utility knife. It is stiff enough to lie smoothly yet still fold crisply around corners.

SpiderLath also has foam-rubber furring strips spaced 6 in. on center that not only hold the material off the wall—allowing mortar to squeeze through and get a good grip—but that also seal every staple penetration through the felt paper or housewrap. Additionally, I like the product for its durability on the job site. Expanded-metal lath that sits around too long before being used always seems to get mangled into a crinkled mass of unusable rusty scrap metal. Other than the fact that the rubber furring strips get a little gummy when left in the sun, SpiderLath is pretty indestructible.

SpiderLath costs about the same as galvanized lath (about 45¢ per sq. ft.), but it has to be ordered from the manufacturer.

Comments are closed.