Inside Crown Corners

Coping crown molding is more than blindly following tradition. Understand the benefits and learn how to cope joints the right way.

Synopsis: On Tucker Windover’s first day on a finish-carpentry crew, he decided to buck tradition and miter some inside crown molding corners instead of coping them. He quickly learned that some traditions are worth keeping, and in this article he describes the advantages coped corners have over mitered ones: They remain tight even as the wood expands and contracts, they fit well in rooms with minor imperfections, they are more adjustable, and they are more forgiving. He also provides step-by-step instructions for the entire process: mitering the stock, coping the cut, testing the fit, and installing the crown. In a sidebar, finish carpenter Chris Whalen, who has been installing mitered crown for 20 years, provides a contrary view.

I can still remember my first day on a finish-carpentry crew. I spent most of my time keeping one eye on the lead carpenter, trying to pick up as many new tricks as I could. I watched him cope and fit a couple of pieces of crown molding. His movements were fluid. His process looked easy. But I didn’t quite understand why we had to complicate a joint that could be made with two simple miters. I asked if it would be OK to miter the corners instead of coping them, and the lead said, “Go for it—if you can make it look right and convince me that it will stay that way.” So I attempted to do it the easy way, or what I thought would be the easy way. In truth, I didn’t make it through a single room before turning to a coping saw.

I’ve learned a lot since then, and in my opinion, a coped joint is preferable to a miter in several ways. Due to wood movement, miters tend to open at the short point or the long point. A coped corner stays tight as each piece of trim expands and contracts in sync. A coped joint also fits well when installed in a room with minor imperfections, such as one with corners that are out of square or ceilings and walls that are less than straight, level, and plumb. The smallest bump of joint compound can throw a mitered corner out of proper alignment.

A coped joint is also more adjustable. If there is a gap in the joint, you often need only to pry the other end of the trim to squeeze the joint tight. Finally, the coped joint is much more forgiving. This makes it a faster joint to make because there is less fussing over the fit. If a piece of trim is cut slightly short, say by 1/8 in., the gap is covered by the subsequent piece of coped trim. When you’re mitering a corner, any error in length will be revealed.

Still, the coped joint has limitations. Certain crown profiles can’t be coped. In these instances, I create a hybrid joint by coping what’s copable and mitering what’s not. When working with medium-density-fiberboard (MDF) trim, I miter the inside corners instead of coping them. MDF trim is more stable than wood, but when coped, its edges become too fragile. I miter crown when installing it on kitchen cabinets that I know to be straight, level, and square. Also, I find that when preassembling crown for a column or a fireplace mantel, mitering works best.

Some people believe that coping is difficult or time-consuming. I can assure you that with a little practice, coping becomes as easy and as fast as tying your shoes.

Miter the stock

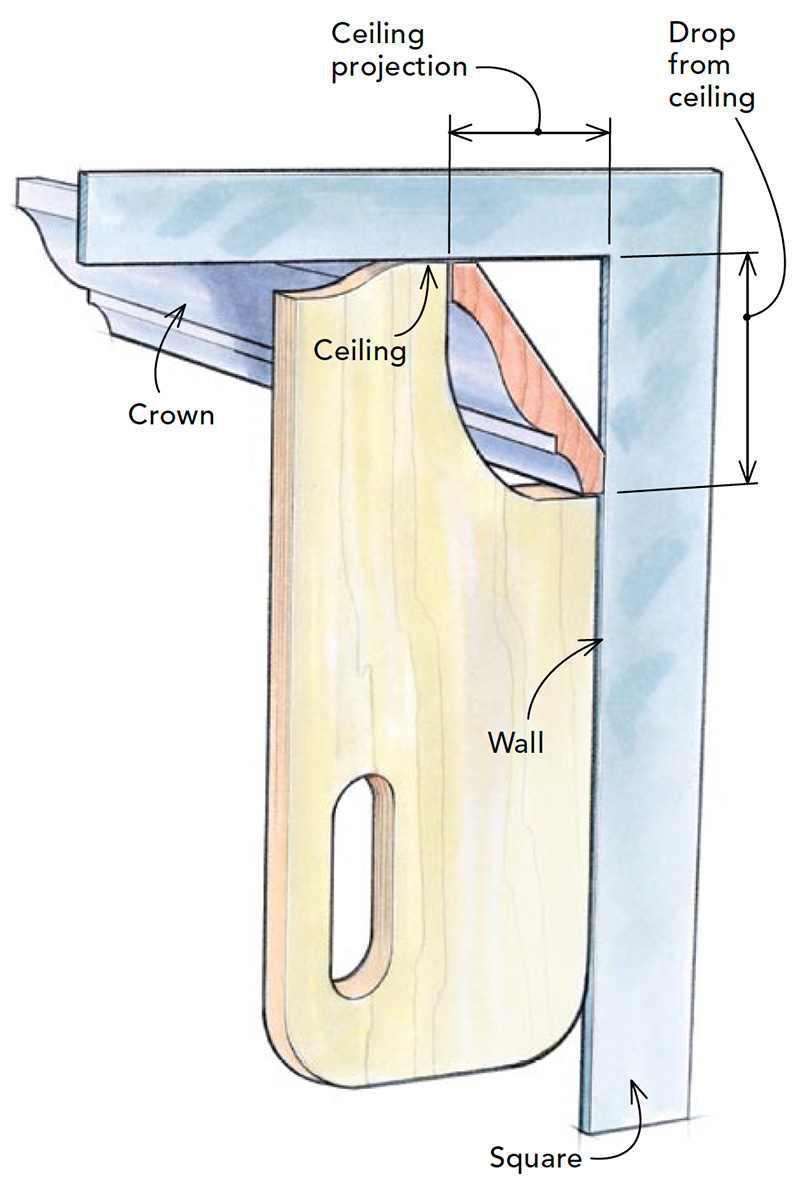

Step 1: To start, make a marking jig. Label the top of a rectangular scrap of 1/2-in. plywood as ceiling and its right side as wall. Measure the molding’s ceiling projection and its drop down the wall by nesting it in a framing square. Transfer these measurements to the piece of plywood, and cut between the points, removing the jig’s corner. This jig will be used to ensure proper crown positioning throughout the cope and the installation.

Step 2: Create a stop that replicates the ceiling position. The distance between the stop and the miter saw’s fence should match the ceiling projection. Check the stop location with the marking jig. This setup guarantees that the molding is cut in the same position as it will be installed.

Step 3: Cut a 45° miter, and measure for length. Place the top edge of the molding down against the stop, and the bottom edge of the crown against the saw’s fence. If coping to the left, the long point of the miter will be at the bottom edge of the crown. Make the miter. Then, using a measurement taken between the corners of the wall, measure from the long point of the miter to mark the trim’s length.

Cope the cut

Step 4: An auxiliary fence helps to secure the trim for the cope. With the ceiling-side edge of the trim flat against the fence and the wall-side edge flat against the stand, snug up a stop to keep it in position. Use the marking jig to be sure that the trim is seated correctly.

Step 5: A jigsaw fitted with a coping foot (collinstool.com) and a Bosch T244D blade increases the speed of the cut. When used correctly, this setup provides a very precise, controlled cope. If the jigsaw doesn’t suit you, there is nothing wrong with using a traditional coping saw. With either tool, make several relief cuts before following the profile of the molding. Hold the saw somewhat less than vertical to give the cope a slight back cut.

|

|

|

Test the fit

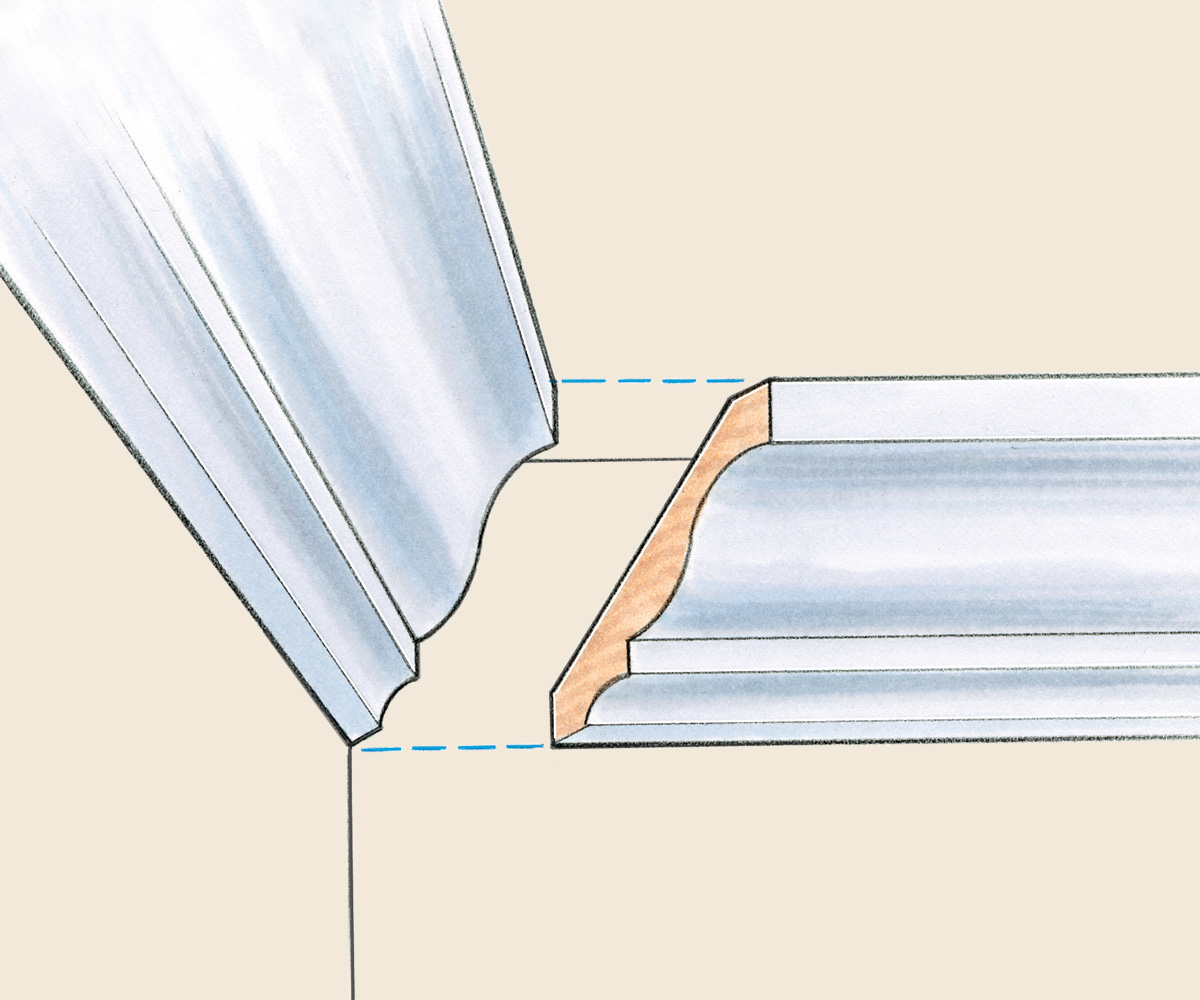

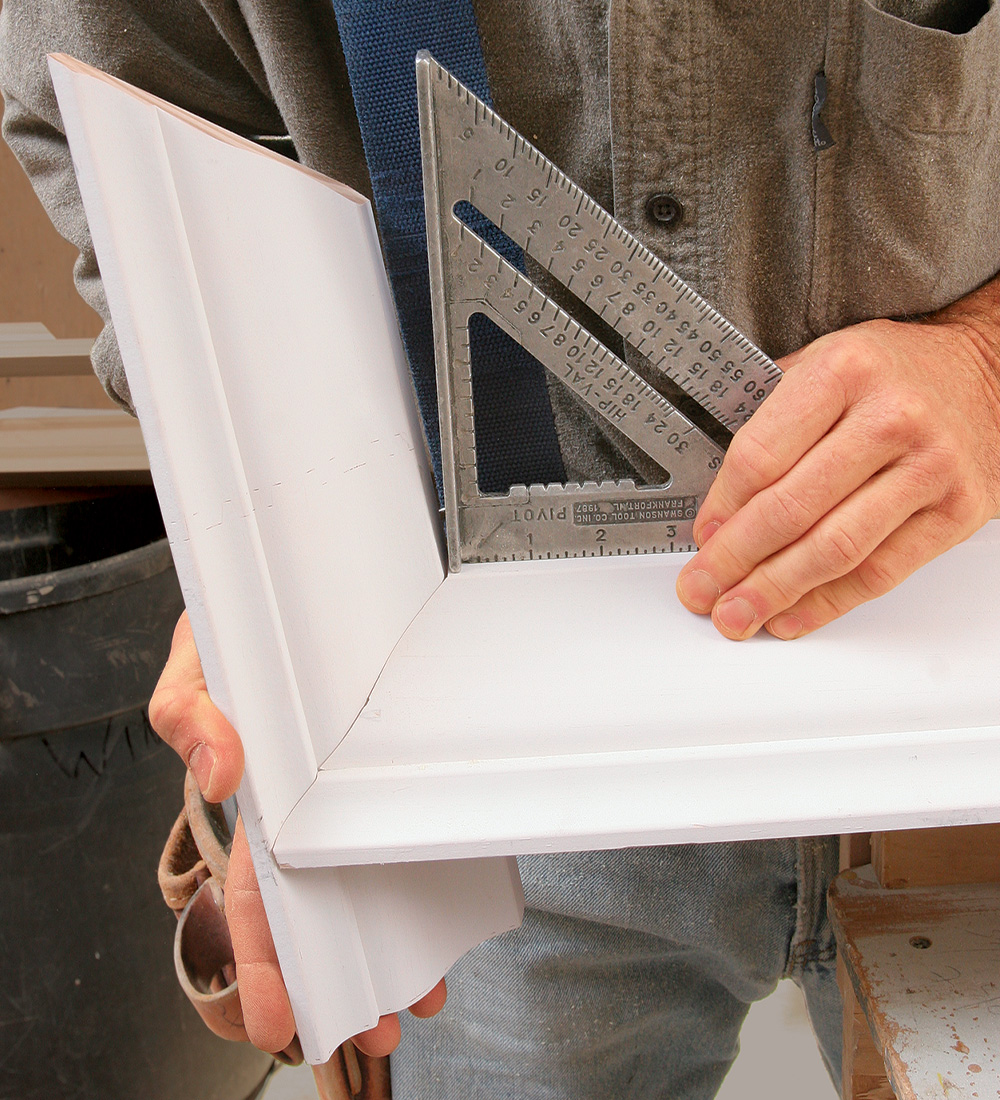

Step 6: Use a scrap of the molding to test the accuracy of the cope. Whether the corner is less than or greater than 90°, the coped joint stays tight. If the joint isn’t as tight as you’d like, fine-tune the cope with a rasp or a sanding sponge.

|

|

Install the Crown

Step 7: Cut the trim to length with a 90° cut. This butt end is covered by the adjacent coped piece of trim. Cut pieces of trim more than 8 ft. 1/8 in. long. The compression helps to keep the corners tight over time. When installing the trim, don’t nail within 2 ft. of each end until the joint fits the way you want it.

Going against the grain: I miterAs a student of two old-school carpenters, I was taught to cope the inside corners of crown molding. I installed my crown that way for 15 years because it was the only way the old guys would allow it to be done. However, 20 years ago, fellow finish carpenter Craig Lawrence suggested to me that it was a lot easier and faster to miter inside corners. I was skeptical, but tried the approach and found that he was correct. Since then, I have mitered all my crown-molding corners with nary a complaint. With the miter approach, you simply set up some stops, pull the trigger, and slice through the stock for a perfect cut every time. I even back-cut each piece a degree or so to accommodate out-of-square corners. If this is not done, the joint will open in front. I leave the ends of the first piece of crown loose until I have the second one up and in position. This allows the corner to be tweaked until it fits. I then glue the pieces together, which I have found helps to form a tight-fitting joint. Finally, I wipe the joint with caulk to blend the pieces together, using colored caulks for stained wood. My advice? Develop a system that works for you, but give miters a try. —Chris Whalen is a finish carpenter in Missoula, Mont. |

From Fine Homebuilding #209

To see this article as a PDF, click the View PDF button below: