Making Wood Countertops

Built well, they’re both attractive and durable, so choose a species, construction style, and finish that fit the way you use your kitchen.

Synopsis: Although the beauty of a well-crafted wood countertop is obvious, its durability is not. Dan Vos, a custom woodworker who specializes in countertops, shows in this article how to construct a countertop that is both beautiful and durable enough to hold up under the challenging conditions of a kitchen. He discusses the importance of choosing a species and then provides step-by-step instructions on milling the stock, gluing up the blank, shaping and sanding the top, and finishing the counter. Although these instructions (and the accompanying photos) cover the process for making a face-grain countertop, Vos describes the benefits and drawbacks of making edge-grain and end-grain countertops as well. He concludes with a list of steps to take during installation to ensure that the wood’s natural movement can occur and that the counter is sealed against water damage.

The most common thing I hear when people first see my wood countertops is, “Wow, that’s beautiful. but are wood countertops durable enough for a kitchen?” my answer is, “mine are.”

Having made a career of building wood countertops, I’ve developed construction methods and finishing techniques that make them both durable and beautiful. Beauty comes from the nature of wood itself, from the way I orient its grain, and from the finish I apply to it. Durability comes from design and construction specifications appropriate for the use of the top. For instance, no matter how much you love the way that it looks, a face-grain pine top is not an appropriate chopping surface. Pine is soft, and face-grain construction is not durable enough to handle pressure from knives.

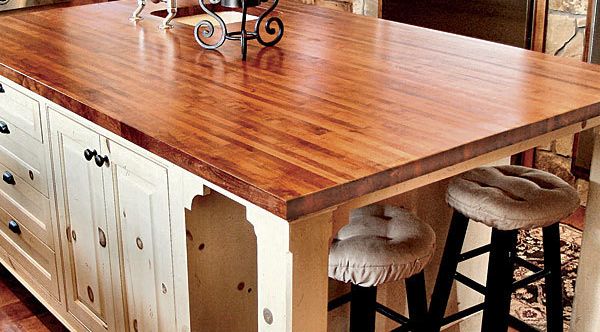

My shop is production-oriented with special tools and work surfaces that allow us to build large, complicated countertops efficiently. But as you’ll see in the process of making the face-grain walnut island counter shown in this article, all you need to make a wood counter is a large work surface, a jointer, a planer, a router, a random-orbit sander, and a handful of bar clamps. Before you jump into a countertop project, though, it’s a good idea to explore the aesthetics and durability of different wood species and three types of construction for wood counters. Then you can determine if a top like this one is right for you.

Choose a wood you like, and expect it to change color and move

I try to guide my clients toward a wood species and grain orientation that appeals to their aesthetics and also suits how they will use the countertop. Where nothing more than a tough chopping surface is what the client wants, I usually recommend an endgrain top of hard sugar maple (more on grain orientation later). When a homeowner wants visual interest, there are lots of wood species that make great face-grain or edge-grain tops. among domestic hardwoods, cherry, walnut, beech, and oak are good choices; among tropical hardwoods, sipo, santos, african mahogany, and jatoba (brazil ian cherry) are all stable and are all easy to work with.

I don’t get caught up with the hardness ratings of various wood species, but I avoid some that are either inordinately difficult to work or are better suited to outdoor use, including cypress, cedar, and hemlock. also, some of the super-hard tropical woods, such as bloodwood and ipé, have problems with end-checking.

Bear in mind that wood can change color over time due to age, ambient conditions, or the type of finish you use. For example, the tung-oil-based finishes I use bring out amber tones in lighter woods, and they deepen and enrich darker species.

Once you determine which species to use, make sure to buy kiln-dried stock to minimize the potential for movement. I test one or two boards from every order to be sure the moisture content is between 6% and 9%. Still, every board and every top will move, especially across the grain. you have to take that movement into account when you build and install a wood top.

For more photos and details, click the View PDF button below: