Tablesaw Accident Sparks Million-Dollar Finger

A couple of weeks ago, Fine Woodworking senior editor Tom McKenna made a guest appearance here at FineHomebuilding.com to fill us in on the story of one Carlos Osorio. Osorio recently won a $1.5 million judgment against the makers of Ryobi tools after suffering injuries to his fingers in a tablesaw-related accident.

A Boston court sided with Osorio’s contention, that Ryobi’s tablesaw design was defective because it didn’t incorporate “flesh detection technology.” According to the Oregonian, now 60 other cases have popped up across the United States, all claiming negligence on the part of tool manufacturers.

|

||

| Steve Gass reflects on his invention of the SawStop. |

So where does responsibility of one’s actions–one’s own negligence in using a tool safely and properly–end? It’s widely known that Gass developed the SawStop technology as just that–a stand-alone technology. But when faced with manufacturers who felt “safety doesn’t sell,” he put his money where his mouth was, financed his own business, built his own saw, and the rest is history.

Does the fact that tool manufacturers declined to license Gass’ technology mean they’re now responsible for any injury related to their tools – whether due to user error or not? The fact of the matter is, there is no federal regulation requiring tablesaw manufacturers to incorporate “flesh detection technology” (say that five times fast), so where is the merit in these lawsuits?

|

| Read Gary Katz’s article on tablesaw safety |

SawStop technology works, and I wouldn’t mind seeing it on every tool on the market, but unless the government passes legislation requiring saw brakes to be incorporated into all new saw designs going forward, the idea of holding every saw manufacturer other than SawStop hostage seems like one very slippery slope.

So where do you stand? A small group of FHB editors recently debated this subject on the weekly Lunch Pail Podcast and you can rest assured that we’ll be revisiting it in the coming weeks. To help us gain some perspective from Fine Homebuilding readers, please take a moment to chime in using the online poll located on page two of this post.

Consider the question, catch the podcast, and cast your vote in our online poll. As we continue our coverage of this developing story, we’d like to gauge how our readers feel about the subject.

|

After you’ve cast your vote, be sure to catch the debate as our editors hash it out on Fine Homebuilding’s weekly Lunch Pail Podcast. |

|

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

8067 All-Weather Flashing Tape

Reliable Crimp Connectors

Handy Heat Gun

When it comes to tablesaw injuries, where does personal responsibility end and manufacturer liability begin?

View Comments

If this law suit lead to saw stop tech in all saws I am glad my too larger saws will last me until I retire.

Of course many portable saws on the market are crap and unsafe anyway but the Saw stop tech on the job site cutting wet and or pressure treated wood I think would lead to many false trips. especially since the only saw now sold with this technology is the Saw stop saws and I think they still hold the paten.

If I'd had the SawStop twenty some years ago, I'd probably still have all the bone as well as full mobility and full feeling in all the fingers of my left hand. On the other hand, so to speak, if I hadn't been doing something incredibly stupid, and if I hadn't had such a cavalier attitude toward safety, I never would have run those fingers through the saw.

I hold myself entirely accountable for my accident. In fact, I don't even like calling it an accident, as it was fully preventable through ordinary care. Language matters. We should refer to fewer events as accidents. Calling something an accident suggests that no one had control over the event, and that's rarely the case beyond say, getting whacked by a meteorite.

And as someone who's utterly fed up with the ever increasing power both the government and self-anointed safety police have over my life, I think both the lawsuit and the idea of further regulation are over the top. I'll accept the risks and the penalties, thank you very much.

MFournier: You hit the nail on the head with regards to the problems the technology would encounter with portable circular saws. Wet or even slightly moist lumber is of course going to cause lots of unintended trips of the brake. That said, I remain hopeful that a way will be found to get around that problem. Perhaps a way might be found to differentiate between the electrical continuity provided by a human finger as opposed to wet wood. I'm no electrical engineer but that's where I'd put my money. Cheers, Ed

Let me state my potential bias right at the outset - I'm a retired personal injury atty. I defended companies rather than sue them but I made my money via lawsuits none the less. Two main comments: First the law is a problem because most "defective product" lawsuits don't easily let a jury weigh the negligence of the saw operator. The negligence theory is dropped before trial begins so the jury is mostly left with deciding whether the product is "defective" and whether the defect caused the harm. A defect can be the absence of a safety device that is readily available and inexpensive compared to the potential harm. That leads me to the second point - juries are the only thing that keeps the system remotely honest. I don't know if this was a jury verdict or not ( a judge could have been the decision maker) but juries really do make the right decision most of the time. Even when we give them some convoluted legal theory, they'll generally figure it out.

Personally, I think a reasonably priced technology that will minimize 60,000 table saw accidents and 3000 amputations should AT LEAST be offered as an option by saw makers - but I respect opinions to the contrary.

It is a cost issue and consumers are on both sides of the coin. Consumers want the technology, hold companies responsible for not including the technology, yet clearly demonstrated they are unwilling to pay the higher price for products that include the technology. Consumer can buy directly from Gass and SawStop.

The easiest way out is for table saw manufactures to licenses the technology for a limited number of models and charge the price demanded for the inclusion of the technology. Then consumers have to decided "do they feel lucky" or not; are they willing to learn and take adequate care using older technology at their own peril; or do they want to pay for innovation. I think saw maker were short sighted in their decision not to license. True financial reponsible rests with the consumer when the product is available directly from SawStop. Licensing the technology recognizes and rewards Steve Gass' innovation and places the burden of choice on the consumer. In the long run this approach would reward Gass AND will more than likely, with time, become a standard option for table saws. Basic economics in a capitalist society. All tablesaw produced without the technology can include the general American CYA warning label and standard instructions on proper operation.

I think the bigger issue in these lawsuits is American's are hurting economically and looking for the first opportunity to reduce the hurt and we have provided a legal system that supports this approach. If the system did not support this approach, I suspect most of these individuals would chalk their accidents up to operator error and acknowledge the very pain full but real lesson learned.

Blood will flow when flesh and steel are one...Sting

I would like to see some of the other table saw manufacturers pony up the licence fee and offer sawstop technology giving myself and fellow woodworkers more choice in getting the brand we want and the sawstop technology as well.

Are you listening Delta, General, Jet, Powermatic etc

This case will encourage more law suits trying to make a killing in the 'jury lottery', which is heavily out of control and biased for the "injured party" who does not take responsibility for his own actions. This case used the same "logic" that cost Piper Aircraft over $2M, when a person sued because a 45 year old airplane did not have seatbelts when he CHOSE to crash it into a truck on purpose.

Unless somehow legislation gets passed that juries are required to find that individuals accept responsiblity for the obvious risks they choose to take, then there will be more suits and more lawyers willing to file for their 30-75% of the judgements.

8% of respondents have voted legitimate in the poll and 92% reported frivolous. That said, despite the overwhelming numbers who see the lawsuit in a negative light, it seems like most of you still want to see the technology in as many saws as possible. It's an interesting dichotomy, to be sure.

I'm still left wondering as to whether or not it will be possible - some day - to use this technology in portable circular saws. The moist lumber issue is a major stumbling block but I wonder if there's another measurement (as opposed to conductivity moist skin which could ALSO trip in moist wood) that could be employed here. Any ideas? Who is an electrical engineer out there? Come on - we've got to have ONE!

I personally can't imagine how this verdict could have been reached. There's a rule of Evidence, Rule 407, that says as follows: [quote]Rule 407. Subsequent Remedial Measures

When, after an injury or harm allegedly caused by an event, measures are taken that, if taken previously, would have made the injury or harm less likely to occur, evidence of the subsequent measures is not admissible to prove negligence, culpable conduct, a defect in a product, a defect in a product's design, or a need for a warning or instruction. This rule does not require the exclusion of evidence of subsequent measures when offered for another purpose, such as proving ownership, control, or feasibility of precautionary measures, if controverted, or impeachment.[/quote]

And here's another one, from the "Law and Economics" realm. The economist Coase won the 1961 Nobel Prize for what we now call the "Coase Theorem," which states more or less that "in the absence of transactions costs the allocation of legal rules favoring one party over another does not matter-- the economically efficient outcome is reached regardless." That's a mouthful, but applying it here, the creation of a legal entitlement to Sawstop technology will simply force manufacturers to adopt the technology-- anyone who doesn't will have potential economic loss in the form of exposure to judgments like this one, which will raise the price of every saw on the market. Every new buyer will be forced to pay a "tax" on the enhanced safety of the new saws, which effectively "internalizes" the economic cost of missing fingers (direct medical expenses, lost wages, lost productivity, social losses etc) back on the buyer of table saws in the first place. Given the universality of the legal precedent, no manufacturer will be able to avoid it, and so the cost ends up with the person who's supposed to avoid it in the first place-- the purchaser.

Approx 14 years ago in a basement shop using a 10 inch Craftsman Tablesaw, I got in a hurry and without thinking, reached across the top of the saw blade (I had removed the blade guard)) to push a scrap cut-off piece out of the way. This tablesaw always vibrated somewhat and I feared the cut-off was going to be flung back in my direction.

The tip of my right thumb was struck by the spinng blade. Fortunately for me, it was a severe laceration, but did not stike the bone...nevertheless, it required plastic surgery to fix it.

The tablesaw vibration was not my doing, but removing the blade guard and stupidily reaching overtop the spinning blade was my doing. I had no one to blame but myself. Did I attempt to sue Craftsman? Heck no!

It's very sad that our country has become a place inhabitated by whiners, who think they are no longer responsible for their own actions. I am sorry that Mr. Osorio got his hand mangled. That no doubt is a shame. But I seriously doubt that the Ryobi tablesaw he was using caused his injury. The saw played a part in that it was the tool being used when the injury occurred, but I doubt the saw blade jumped out and attacked Mr. Osorio's hand!

Lets see, Mr. Osorio had several options prior to his accident. He could have purchased a Saw Stop, if that was the safety measure he really wanted to employ....but he did not. He could have sought to cut the wood using a different tool or device to lesson his chance of danger with the table saw he was using... but again, he chose not to.

Instead, he consciously chose to purchase the Ryobi instead of a SAW STOP, and he chose to use the Ryobi in such a manner that he got his hand mangled because of it.

THE ONLY WAY a person can get his hand mangled is by consciously removing and/or discarding the safety devices that normally come with the saw. If he did not remove them, then someone else did.

Nevertheless, he being the operator of such equipment, he has the final RESPONSIBILITY in determinig whether or not it is safe for him to use this tool in its present condition. And, failure to adhere to the manufacturer's mandated guidelines for safety precautions is again, his decision, and his full responsibility... not the manufacturer. Had he felt the Ryobi set-up was dangerous, he had the option to walk away and figure out another way to make the same type of cut....but he chose not to do this.

Seeing how he got all mangled up, its safe to say HE DID NOT OPERATE THE SAW IN A SAFE MANNER.

Everything that went wrong, he had control over to initially change or alter;...but he chose not to. Saw manufacturers should not be held accountable for this. Our lawyers and judges no longer know the meaning of "Common Sense" when reviewing these types of cases. That's why this country is going to hell.

Davo

Rule 407 doesn't apply here because the accused did not take any subsequent measure to remedy an error. Ryobi is not charged with applying safeguards after an incident to correct a mistake in manufacturing and cover their asses. That rule protect Ryobi in the case where the Prosecution charges Ryobi with negligence and proving it by saying they (Ryobi) knew they made a defective product and the safeguards they put in place after an incident proves that they knew their product wasn't safe.

i like the concept of having a tool operator choose to pay a premium for the technology. It seems to me that by having the buyer/operator choose the level of safety, they are making an explicit admission about their negligence if an accident occurs. I do not believe the safety equipment should be required but would like it as an option.

IIRC, saw manufacturers declined to use the 'saw stop' because their lawyers said it would increase their liability, and cause all manner of other claims.

We see, instead, this case making an oleo of various different legal doctrines. I'm not happy with that; we need a predictable legal climate in order for business to function.

As a workplace injury, one would expect 'workmans' comp' rules to apply. I don't know why that did not happen here.

One of the first cases to illustrate the limits to 'safety' legislation involved a table saw guard, the "Brett Guard." In the end, OSHA was forced to allow the use of this guard as an alternative to what was prescribed by their regulations.

I was, at that time, looked at with amazement by others ... as mine was the ONLY saw that had any manner of guarding. All other saws had had the guards removed. I have to wonder about the saw in this accident ... where were the guards?

As I post this, the guy across the alley from me is celebrating a year since he lost most of his hand, in an at-home accident with his table saw. Do you think he will now try to sue?

Let's assume that the 'saw stop' becomes mandatory. I can think of many bad things that will happen .... the least of which will be the greatly increased value of 'pre-ban' saws!

I'm sorry the man got hurt, but $1.5 million won't grow his finger back.

If the Saw Stop was available when the man purchased his Ryobi saw than shame on him. And I bet the jury where home owners and not tradesman. And bottom line where does personal responsibility come in. You cannot idiot proof everything, because someone will invent a better idiot?

I think in order to fully understand this and make any sort of decision, the idea behind the saw needs to be stated. It is a tool desinged to cut material. Any tool, (no matter what kind), is only as capable as the person operating it. We all know table saws are dangerous; and we've known this since 7th or 8th grade shop. The fact that a lapse in judgement caused this man to lose part of his flesh, I believe, is irrelevant to his point. He indicates it was defective because it did not incorporate something it wasn't designed for. If Ryobi's design called for a safety device to cut the power when flesh was present, AND it failed, THEN they are responsible for producing a defective product. To rule against a company because it did not take on extra liability and potentially cause the demise of their product line from buyers that want a saw that works all of the time, I believe, is wrong.

The lawsuit is frivolous, but you did not ask whether SawStop (TM) technology should be required. Laws required auto makers to provide seat belts and air bags because the technology was available and there was a public interest in preventing unnecessary deaths and injuries. I am hoping that other manufacturers will provide this safety feature on their table saws so there continues to be some competition in the market. I plan to upgrade my table saw in the next year or two and it would be difficult for me to buy a saw that does not contain this safety feature. I would like to see this technology become available for other large power tools as well.

I sympathise with people who have damaged themselves using tablesaws. I have used mine for 30 years and have avoided serious injury by sticking to rules about where I put my hands and always having a riving knife fitted.

In the U.K we have regulations which cover the use of all machinery and tablesaws must always have guards etc fitted. The operatives must be trained in their use. Braking must be fitted, even on saws manufactured before the date of legislation. These regulations are to protect workers from themselves and from employers who would have them use dangerous machines. If an injury occurs, or an inspection reveals faulty machinery or working practises the employer can be fined or imprisoned. Injury from tablesaws is reduced by new legislation.

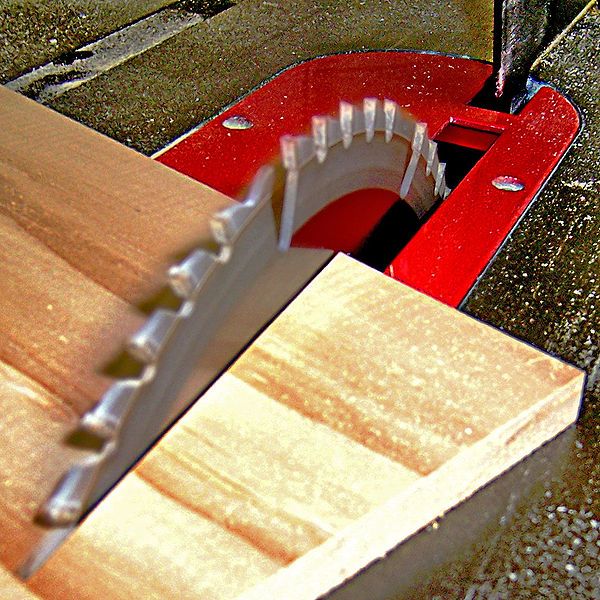

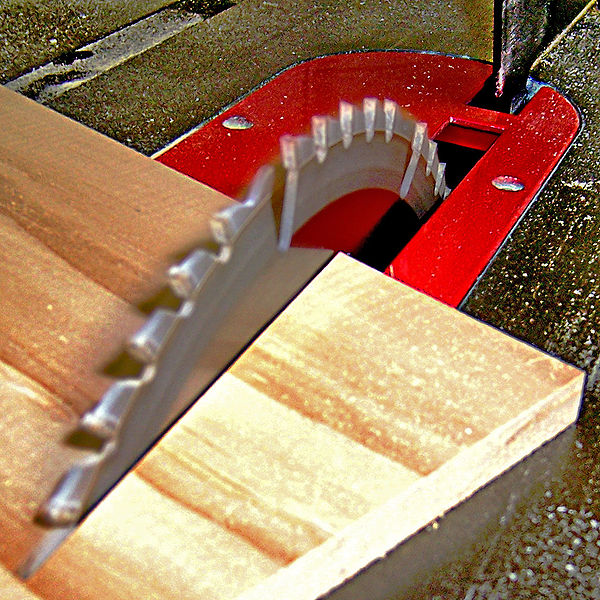

Incidentally page five of Gary Katz's article on tablesaw safety shows a fence fitted stop which is in my opinion much too thin. It should be at least 2" to leave a gap large enough to allow the cut piece to be slid out easily and prevent vibration causing it to it rotate into the blade.

The first link is to the U.K Govt. document on safe working practices for circular saws, the second to a legal action for injury to an employee.

http://www.hse.gov.uk/PUBNS/wis16.pdf

http://www.hse.gov.uk/press/2006/gnn141416p.htm

Maybe some day an evolved version of the technology will be appropriate to include in all saws. But as it is now I could not cut any conductive material with a Saw Stop saw. I do sometimes use my cabinet saw with an appropriate blade to cut aluminum angle and similar things. OK, so maybe they make it so you can turn it off, but then we will see a suit saying the saw maker allowed the user to forget to turn it back on.

Bob Wilson

All the technology in the world, or even generations from now will never defend against "Stupid is, as stupid does" (I forget who said this)

It won't be long, in this sue crazy country, and someone will have to develope a devise similar to sawstop for hand saws, kitchen knives, machetes, etc., etc.,etc.

Lawsuits and legal BS is what is destroying our way of life! Plain and simple. Look, you can not engineer stupid! I think the SAW STOP stuff is great for the beginner or the classroom or whatever but machines of all types have to have your respect. If you are stupid enough to attempt to stop a rotating motor pulley with your hand and loose a finger in the process, who should be to blame? Well, to me the answer is simple - you're the idiot.

All the guards and technology in the world will never stop someone from loosing a finger, an eye or worse and you can not, nor should you, make it the responsibility of the manuafacturer. Their liability should end with the purchase of the equipment.

When I was in school and we had to watch those goofy movies from WCB about the dangers of woodworking machines they taught you not to waer loose clothing, not to have jewlery on and not to play around whilst equipment was operating. In these cases are we now saying that you can present legal action against the clothing industry because you had a tie on or loose clothing? I mean come on where is the common sense these days people?

Ok, end of rant.

Cheers

I've had my own close call when I lost the finger nails on three fingers. I was careless and in a hurry, I was stupid. I have great sympathy for anyone who gets hurt when using their tools but it almost always comes down to operator error. For that reason, we can't blame the tool manufacturer.

I fear the day when we are required to provide such table saws on the jobsite because of lawsuits like this. Wages are low enough without employers cutting into the net income to cover themselves from loss by requiring employees to buy tools with this kind of safety provision. That is how it will go because most employers (non-union at least) expect the employees to bear costs such as this.

I am not sure of the merits of this law suit. That said, I think we are indebted to Steve Gass for getting American table saw safety out of the dark ages. When the industry turned its forward thinking back on him and his invention, he didn't give up. Forced to build his own saw, he added a proper riving knife, which European saws have had for many decades (Those #@**& socialist, taking worker safety seriously). Now all the new American table saws have them. Thanks Steve!

There is always going to be opportunist in every society and low life lawyers looking to "score the big class action lawsuits" that would make both fame and fortune. These frivolous lawsuits would never get traction if judges would cease to be legislators "public policy makers", activist, etc. all around bottom feeding scum suckers. I miss logic and respect of law.

I recently got a splinter and I couldn't get it out and I got an infection. Do I sue the tree or the supplier?

Wait until all the illegal immigrants get a hold of this case. Tablesaw sales are going to skyrocket!!!!!!!!

I have a question. Does a Saw Stop function when the saw is turned off and the blade is still moving?

A shop is a serious place but I have a problem. If every saw in a Shop has to have this technology then what happens when a pissed off person turns on all the saws and touches the blade on the side? No harm to the person but a lot of financial damage to the shop. I may be stretching the situation, but personally I have been hurt by a table saw and I would not own a Saw Stop saw. I have been a woodworker for over 35 years and the one time I got hurt was a totally freak accident. I have talked to a number of people and we all say that I could not duplicate the accident again. Stuff happens and all we can do is try our best not to be hurt. I do not want people making decisions just to sell equipment.

I am all about shop safety and as a general rule I am all for anything that makes tools and my work place safer. The first thing my son and I ever made together with a power tool was a push stick. That said, I noticed that I couldn't find a price for this SAW STOP item anywhere on the internet. I kind of got the idea that people want to suck you in to see how well it works before they tell you what it costs; because we all know "you can't put a price on safety." Except, that we do so every day.

I work in highway construction and between our agency and our industry partners, we lose more than a couple people a year to motor vehicle collisions in the jobsite. The easiest way to stop that would be to close the roads during working hours. Of course that will never happen because the economic disruption would be tremendous. By the same token, NASCAR drivers walk away from high speed wrecks all the time. But passenger cars built to NASCAR standards would be too expensive for anyone to buy. Of course that would make my workplace a lot safer...; but, also a lot less necessary.

My point is we make decisions about how much safety is enough and how much "insurance" we can afford to buy every day. We just don't usually lay it out quite so explicitly - usually it's hidden in a layer of euphemism or obfuscation to make the medicine a little more palatable. This Saw Stop thing will be great if it's affordable, but if these lawsuits are going to price table saws off the market, what good is it? Is that really going to make anyone safer?

I haven't had a saw accident in my 30 years approx. carpentry and more recently cabinetmaking, but if I was going to buy a new saw, and I could afford a Saw-Stop, I would buy it. As to the law suit, your legal system in USA had gone completely mad, allowing a case like this to succeed; and ours in Australia is heading the same way. When does an individual cease to accept any responsibility? Looks like they never have to do so, if this case is anything to ponder. While I feel sorry for anyone losing any part of their body in an accident, we (the public, manufacturers, government) can't be expected to accept the bill for in some cases, stupidity

No matter how carefull we all are we will all have small cuts and bumps. Why should we blame the people who make the tool when most problems are ones we create on are own. I have been hurt two times in over fourty wears of wood working and both time were my own fault. In fact I just had to have skin grafts on two fingers last week for getting in a rush checking out a router table depth set up before I set up my finger boards. I came very close to losing two fingers for being in a hurry so who is to blame, I AM no one else.

OSHA controls a lot of the tools that we now use but it is still up to us to use them in a safe way.

Here we are, 92% of respondents to this poll cannot see the forest through the trees. No one is debating that accidents on TS' are ones own fault. It does not matter what the excuse is. This demented machismo and twisted logic against saw stop tech has to give way to safty. I, and anyone else will still follow safty protocals when working on a TS, an exposed spinning blade still has comanding respect no matter what tech is designed into the tool.

If the tech was implimented when it 1st came out, all this trash talk would be a none issue and 10s of thousands of accidents would have never have happened, period. This law suit is just the tip of the iceberg, wait untill the patent runs out and ALL manufacturer's start comming out with saw stop tech touting a "NEW ERA IN TS SAFTY". ANYONE who gets hurt with conventional pre-sawstop TS' will be compelled to sue the pants off manufacturers since the tech has existed for many a moon and the manufactures will appear neglegent in implementing it, reguardless as to how many of you feel. The writing is on the wall and clear to see. Lets just hope that the costs that will likly be pasted on to the consumer from these lawsuits doesn't turn around and bankrupt the manufacturers.

I hope that this guy in the lawsuit gets all his $$$. There will be legions of lawyers lining up to get their share of the pie all because the lack of that ounce of prevention now requires a ton of cure.

Yes, one must allways accept personal responsibility, again no one is questioning that but if a device exists that can stem major accidents, why not use it for the geater good and safty of one's customers. Step out of the dark ages boys.

The guys and idiot. How many times have you been in the big box stores and seen Idiot #1 in a blue or orange vest (who doesnt look like he knows which end of a hammer to pick up), walk idiot #2 (Mr. homeowner who just took a 15 min class on building decks and now feels idiot #1 is smart enough to guide his project) over to the powertools and point out the wrong tools for the a specific task? Meanwhile idiot # 3 just walked over from the paint dep. and started throwing in his nonsense too. Now Mr. homeowner walks away with a portable Ryobi tablesaw confident in his newfound abilities completely uneducated about safety, or proper work methods.

Does the typical buyer of a LOW END PORTABLE POWER TOOL know that even though he once saw competent contractor use a tablesaw without a gaurd in place and make it look easy doesnt mean he should? Does he know about things like kickback?

Now I'm not bagging on ryobi's tools because I've seen many skilled people use them on jobs, but people usually buy ryobi because theyre looking for a tool that fits into a certain price point. If all saw manufacturers are required to put Saw Stop tech into theyre tools, does that mean people are all going to be willing the extra money that requires? No. Consumers are still going to want 200$ tablesaws that have all the bells and whistles and look like the real deal. But the saw stop just added money to that tool so now the manufacturer needs to cut cost in other areas. So, if you make a Cheap, Vibrating, Unstable table saw even more cheap, just so you can add a saw stop and still sell it for 200$, Are you really making a safer tool?

You get what you pay for!

Everyone knows a cheap subcompact car isn't as safe as a top of the line auto with roll cage, side impact airbags, and collision avoidance sensors. It's a trade off, cost vs safety devices. We make this trade off with many things in our lives, including the tools we buy.

Eventually the saw-stop technology will trickle down to cheaper saws, but not likely until the patent runs out. The sad thing will be the Govt and trial lawyers running up the cost of tools in an already depressed economy.

With liberty comes responsibility.

Why so much discussion about a suit of which we know only the outcome, and not the path to the decision? Do we suppose that the jury walked in (we don’t seem to know if it was a jury trial) and told the judge “Don’t bother with the presentation; we’ve already decided to award $1.5 million.” Or, did Ryobi send a first year law student who said, “I’m not prepared for this, so Ryobi rests its case.”

Year after bloody year, people injure themselves with saws; what have the manufacturers done to protect their customers? “Safety doesn’t sell?” Only when the manufacturer doesn’t want to cut into profits by looking at their 70 year-old design and actually try to make their saws safer. Think Ford Pinto for an economic decision to keep profits over safety. Years ago, I sold a consignment used Caterpillar D-8 bulldozer to a couple of brothers (they were loggers), but I insisted that they pay to have a ROPS (rollover protection) canopy retrofitted. (Had the dozer been company inventory, we would not sell it without ROPS.) They paid. A few months later, they called and said ‘thanks’. They hadn’t rolled the D-8; they dropped a western red cedar on it. The operator was unscathed. They made a mistake, but certainly not a capital punishment mistake. Similarly, a lax moment sawing a board shouldn’t cost a digit, when there is better technology to prevent or reduce problems.

Since injuries seem to be common with saws, it’s well past time that the manufacturers took responsibility for the safety of their offerings. They have gamed the system for years, judging the cost of improvements against the chance of losing an injury suit. Now, the cost dynamic has changed slightly in favor of the consumer. The cost per unit of safety devices drops with widespread adoption. Insurance will also drop. Trips to the doctor will drop, and society won’t lose the productivity of a craftsman who made a mistake.

Hmmmm...maybe I should also sue my parents for raising such a stupid boy...